Automated warehouse with 2,755 tons of frozen fish and seafood

Conservas Cerqueira automates its raw material warehouse to drive the daily production of one million cans of food.

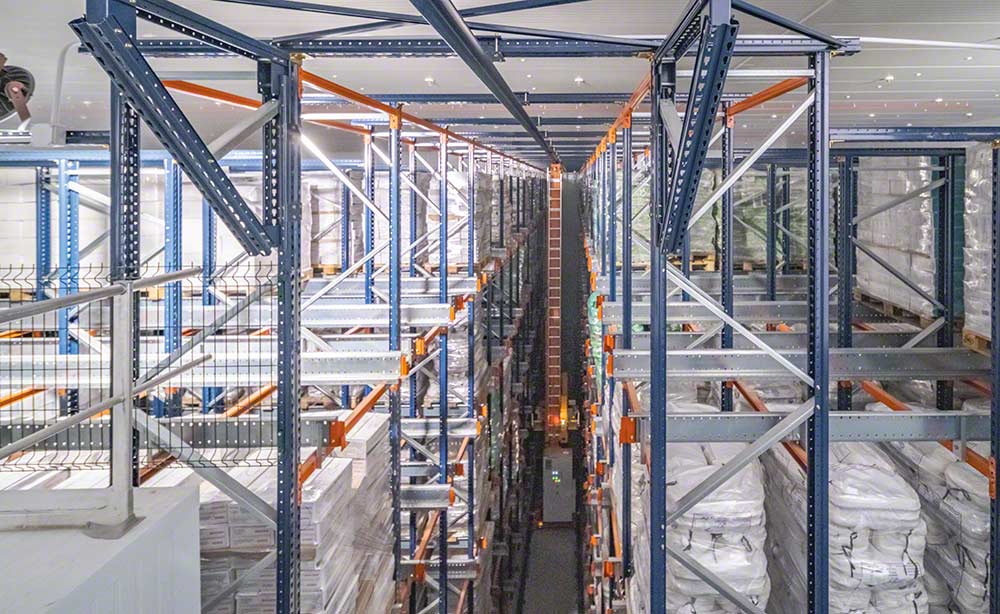

Conservas Cerqueira, which produces and sells canned fish and seafood, has opened its new plant in Rianxo (Galicia). The company has installed the Automated Pallet Shuttle system to house frozen raw materials. The AS/RS is managed by Mecalux’s Easy WMS software.

Conservas Cerqueira: tradition and quality

Conservas Cerqueira is a Spanish company specializing in producing and marketing canned fish and seafood. Founded in 1890, its long-standing tradition in the canning industry is synonymous with high-quality products. Based in Vigo (Spain), the business offers a wide range of canned food, including tuna, sardines, muscles, octopus, and other seafood. Conservas Cerqueira stands out for its commitment to quality, sustainability, and innovation in its manufacturing processes. Conservas Cerqueira has 170 employees, 2 production plants, and a presence on 5 continents. The company has 170 employees, 2 production plants, and a presence on 5 continents.

CHALLENGES

|

SOLUTIONS

|

BENEFITS

|

|---|

Rianxo, a Galician town known for its rich fishing tradition, is home to Conservas Cerqueira’s largest, most technologically advanced, and sustainable manufacturing plant. The megafactory is equipped to produce and package up to one million cans of fish and seafood per day. Between this Rianxo plant and the factory in Vigo, where its headquarters are located, the business manufactures 50 million cans annually. Today, it stands among the top 15 canning companies in Spain.

Conservas Cerqueira’s logistics strategy involved centralizing all its operations. “We needed a space at subzero temperatures to store the raw materials used on our production lines. We chose our Rianxo facility to improve stock management and control, removing the need for third-party storage,” says Antonio Otero, Head of Administration at Conservas Cerqueira Rianxo.

After weighing several options, the company decided to install the Automated Pallet Shuttle system served by a stacker crane. “We chose Mecalux as our storage solution provider because we’ve been working together for many years; we’re familiar with their work and expertise in these types of systems,” says Otero.

Storage at -22 °F

“The new AS/RS houses 2,755 tons of raw material — mainly cephalopods — which are subsequently canned,” says Otero. To operate at a constant temperature of -22 °F, the automated storage and retrieval system (AS/RS) was built with sandwich panels. Mecalux also outfitted it with compressors, condensers, expansion valves, and evaporators to maintain the warehouse at the proper temperature.

The Automated Pallet Shuttle is an ideal high-density AS/RS for meeting food logistics challenges. Its benefits include traceability of perishable products, uninterrupted flow of goods, and optimization of costs linked to temperature control in the warehouse. “We opted to automate because it provides significant energy savings when generating cold air. Additionally, it eliminates the need for operators to access the cold storage area to handle the goods,” says Otero.

The motorized shuttle works in coordination with the stacker crane for pallets to provide a continuous flow of products. “Through automation, we’ve gained more accurate control over the location of our stock and greater speed in inflows and outflows,” says Otero.

Apart from throughput, the Automated Pallet Shuttle has increased storage capacity, accommodating 3,000 pallets in 9,688 ft². Furthermore, it has considerably reduced energy consumption for cooling, as cold air is distributed among a larger number of pallets stored.

Sustainable production

Conservas Cerqueira’s megafactory is a benchmark in sustainability, employing innovative, sustainable production processes such as fish selection and preparation, cooking, packaging, and sterilization. Automating these tasks enhances food safety and compliance with environmental regulations.

The building is equipped with photovoltaic panels that capture solar radiation and convert it into electricity used for production and logistics processes. The plant features a unique sterilization system that optimizes product quality and an innovative water management technique for reuse in various operations.

Fish and seafood traceability

“The Easy WMS warehouse management system ensures complete traceability of stock,” says Otero. The software communicates continuously with Conservas Cerqueira’s SAP ERP system to guarantee the supply of the production lines while maintaining the cold chain.

The fish and seafood sent to suppliers arrive palletized, stretch-wrapped, and labeled. At the inbound checkpoint, Easy WMS identifies the pallets and validates that they meet the established requirements before assigning them a location in the AS/RS. The Mecalux software optimizes storage by taking into account the number of empty positions, the product’s SKU, and its demand level.

To supply the production lines, the ERP informs Easy WMS of the required raw materials so that it can schedule their dispatch as quickly as possible. Digitalization enables Conservas Cerqueira to maintain a steady, continuous production pace.

Digital logistics for Industry 4.0

Conservas Cerqueira’s megafactory in Rianxo, which blends tradition with technology, is prepared to sustain the production of one million cans of fish and seafood a day. Thanks to its logistical capacity, the company has built a reputation as a manufacturer of high-quality canned goods. It ensures that the finest seafood reaches consumers around the world fresh and in optimal condition.

We chose Mecalux as our storage solution provider because we’ve been working together for many years; we’re familiar with their work and expertise in these types of systems.

Gallery

The Automated Pallet Shuttle system at Conservas Cerqueira’s facility

Ask an expert