High-Performance Pick Station

Ergonomic, efficient picking of multiple orders simultaneously.

Product

This automated picking solution greatly increases the number of orders filled.

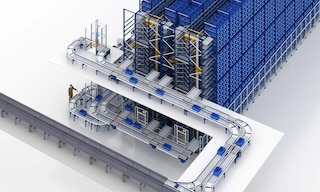

Our high-performance pick station is designed to boost order picking. It provides operators with immediate and direct access to as many boxes or totes as possible when filling orders. It is ideal for high-turnover products, and thanks to its ergonomic design, it facilitates the preparation of up to 6 orders at a time.

The picking station consists of two levels. The totes containing the goods used to fill orders arrive on the top level. The operator removes the products from these totes and places them in a tote on the lower level corresponding to a specific order.

Advantages

Up to 1,000 picks/hour of small and high-turnover products

This system speeds up order picking operations, eliminating trips around the warehouse to locate the various products that make up each order.

- Product receipt via the goods-to-person method: operators automatically receive the boxes or totes containing the items they need to put together orders. Conveyors move the goods expeditiously, reaching speeds of up to 3.3'/min. and avoiding operator travel in the facility.

- Pick-to-tote: operators remove products from the bins brought to them and immediately deposit them in one of the totes. Each tote corresponds to a customer order. Operators can prepare up to 6 orders simultaneously.

- Error elimination: thanks to WMS’s instructions and the help of the pick/put-to-light systems, the risk of error is practically non-existent.

- Safety: the goods-to-person picking station is outfitted with operator safety and protection systems. These include light curtains and a safety perimeter, among others.

- Ergonomics: the picking workstation is designed to make the work of warehouse pickers more ergonomic. The operators themselves can adjust the height of the platform to remove products from boxes as comfortably as possible.

- High work pace: the intuitive use of the system and elimination of warehouse travel lead to peak efficiency in order picking. Throughput is extremely high, reaching 1,000 picks/hour per person and station.

- The system is adaptable to totes weighing up to 110 lb. and unit loads of different sizes. This order-picking workstation can operate at temperatures ranging from 32 °F to 104 °F.

Operation

Ergonomically designed for more agile order picking

Order picking is performed in line with the goods-to-person strategy, the choice method for automated storage and retrieval systems (AS/RS). Operators remain at the high-performance pick station as the goods they require to prepare orders are brought to them. The system works with pick-to-tote: placing all items that make up an order directly in a specific tote streamlines consolidation.

By following this approach, businesses that handle small, high-turnover items can dispatch a large number of orders per day without errors.

This is how our high-performance pick station enables the fulfillment of higher order volumes.

Case Studies

See more case studiesCatalog

High-Performance Pick Station (catalog)

Ergonomic, effective, and productive preparation of multiple orders at once

DownloadAsk an expert