Warehouse modernization and consulting

Warehouse upgrade, improvement, and redesign services to optimize performance and adapt to new logistics needs.

The service

Modernization services for a future-ready warehouse

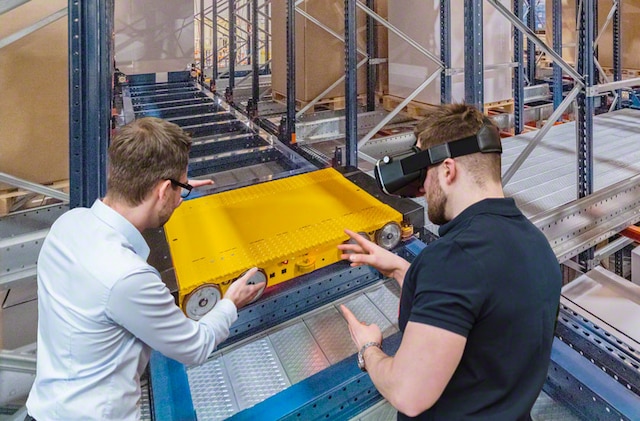

Interlake Mecalux supports its clients as their business evolves. We guide them in transforming their intralogistics operations to meet market demands and supply chain requirements. Drawing on its extensive experience designing and developing storage systems, Interlake Mecalux assesses each organization’s specific needs. It then provides fully customized solutions that respond to critical challenges such as process automation and operational digitalization. Warehouse modernization helps prevent obsolescence and future-proofs facilities by implementing cutting-edge technological solutions. This transformation optimizes operations and expands intralogistics capabilities.

Benefits of warehouse modernization

- Maximum upgrading: modernizing storage systems boosts warehouse efficiency, reliability, and stability. It keeps facilities up to date with state-of-the-art technology and reduces the risk of obsolescence.

- Extended lifecycle: replacing parts, introducing improvements, and regularly updating warehouse control systems help extend the durability of the facility’s automated equipment.

- Performance optimization: increasing storage capacity and introducing innovative solutions for continuous process improvement help logistics centers adapt to changing scenarios.

- Tailored solutions: warehouse redesign and upgrade services are fully customized to meet clients’ requirements. Projects are organized to minimize interference with routine facility operations.

- Comprehensive modernization: Interlake Mecalux’s services cover the entire renovation, from consulting and designing the personalized solution to implementation and ongoing technical support and lifecycle services.

Modernization solutions

Custom projects that transform warehouses to boost growth

Interlake Mecalux offers its clients a wide range of services designed to adapt their facilities to ongoing market and supply chain changes. Based on a thorough assessment of each company’s needs, Interlake Mecalux designs and carries out modernization projects that boost performance, increase productivity, and extend the warehouse’s lifespan.

Testimonials

Case studies

See more case studiesAsk an expert