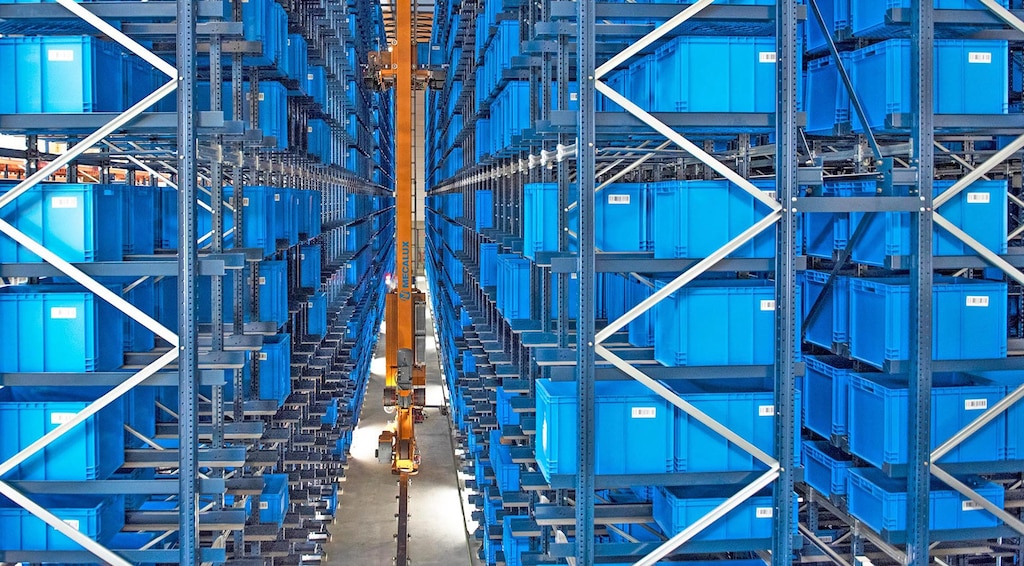

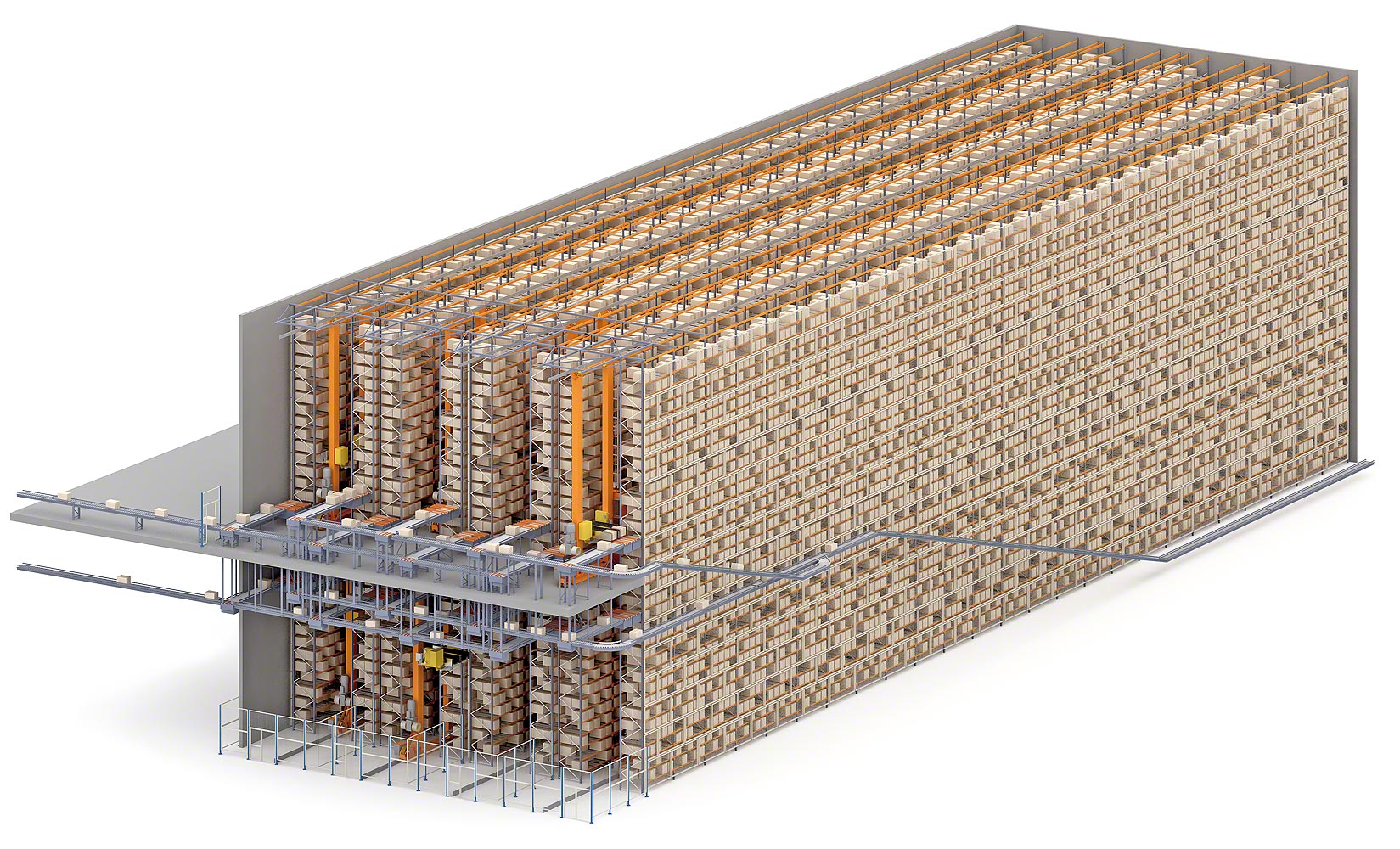

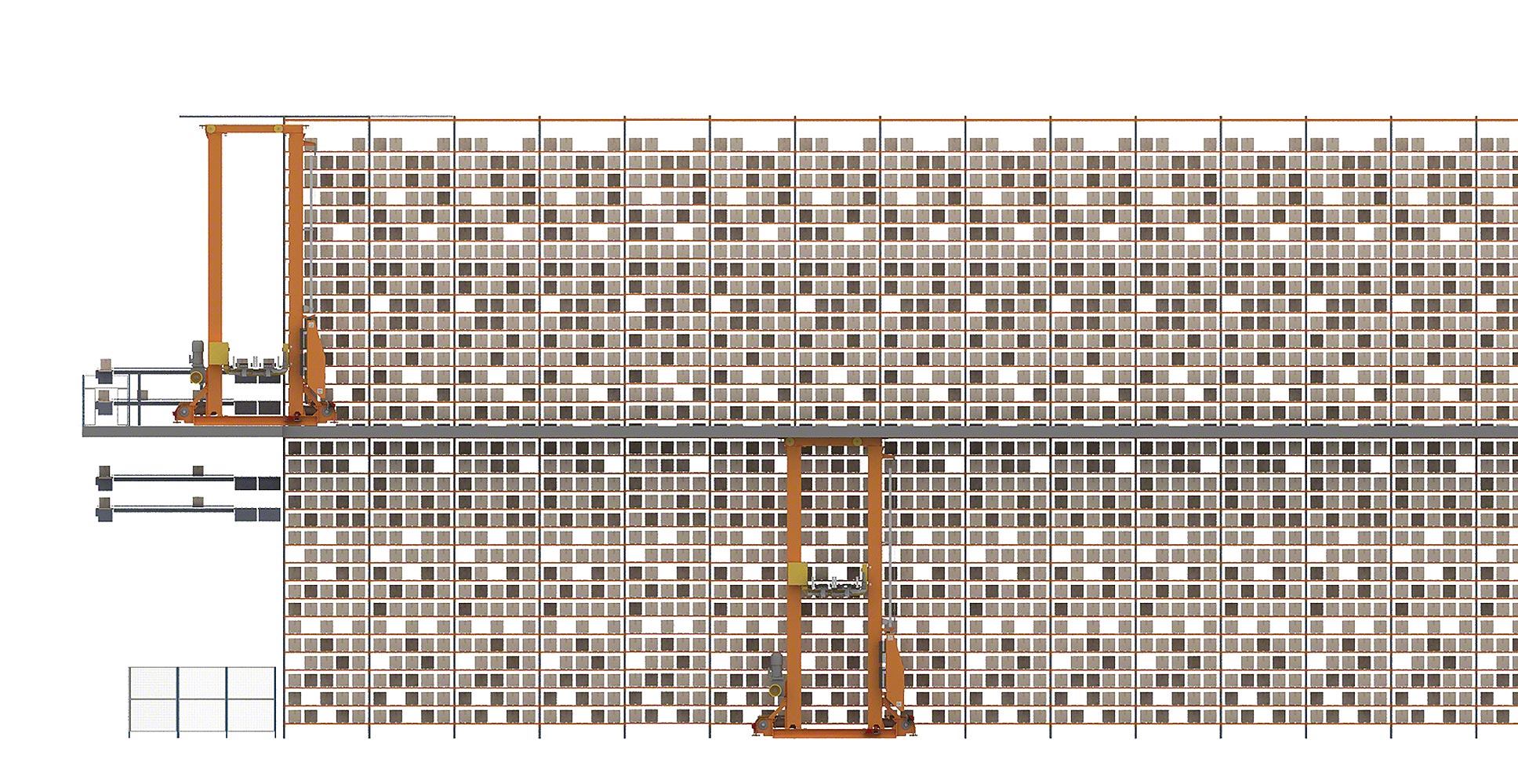

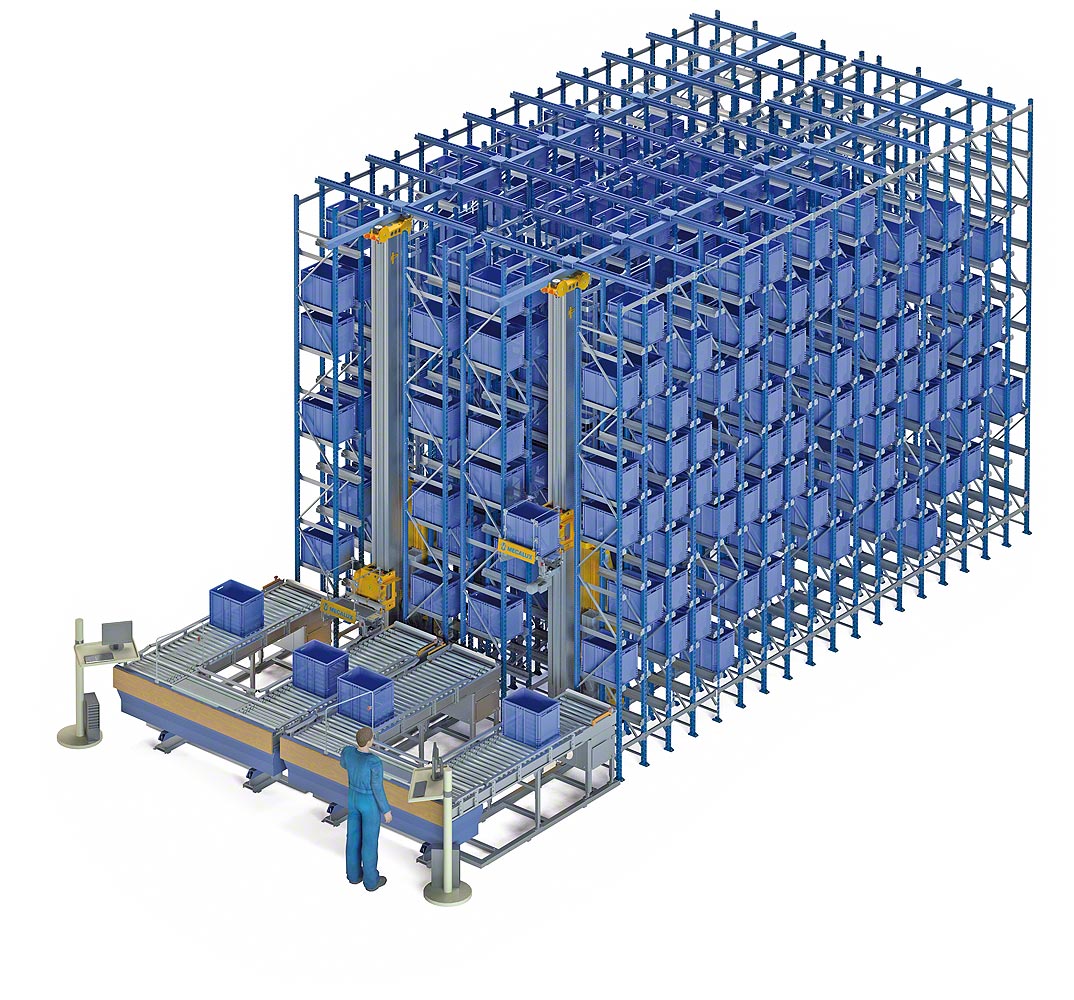

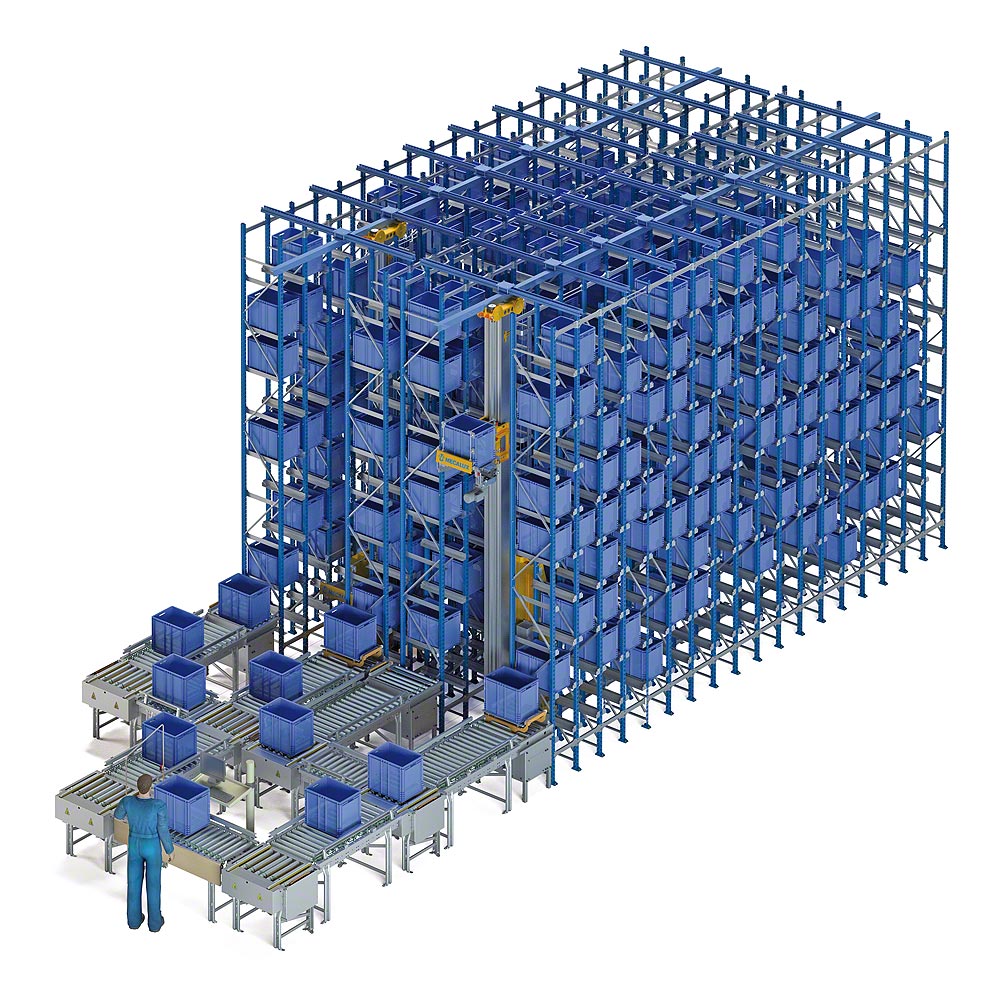

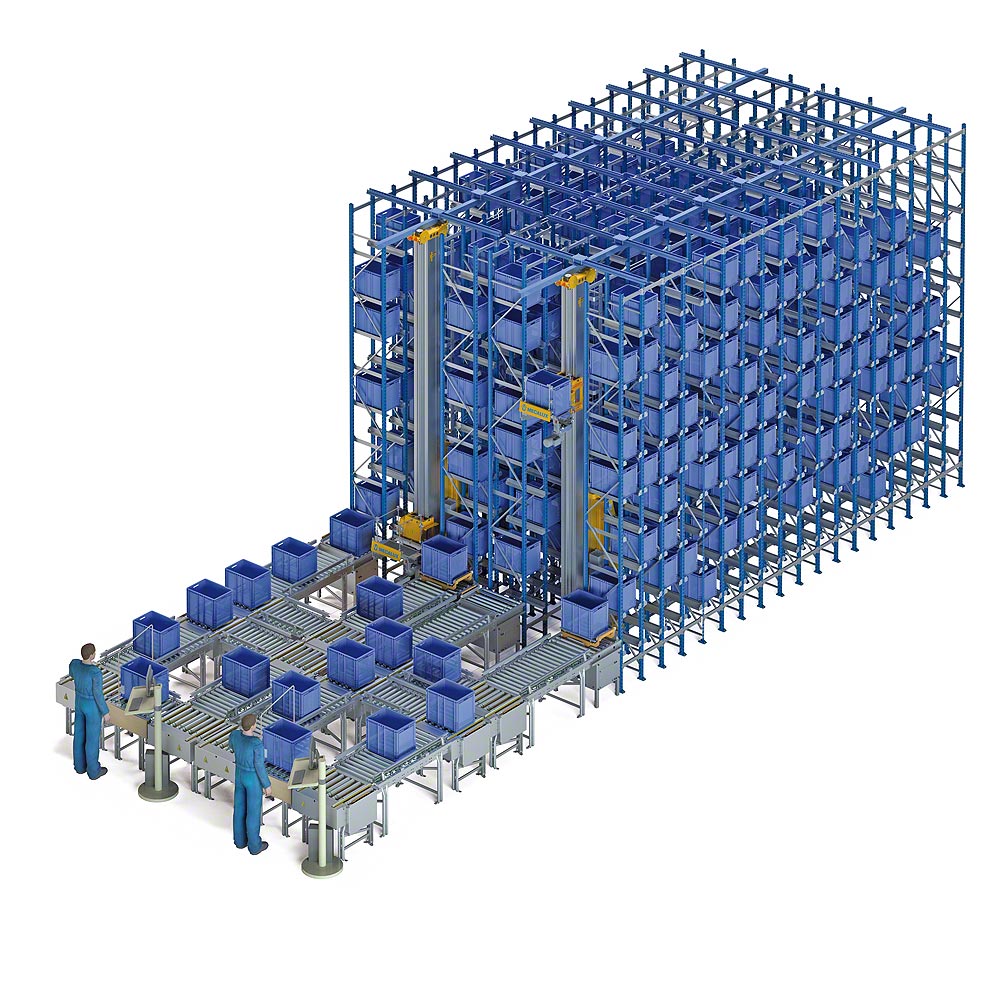

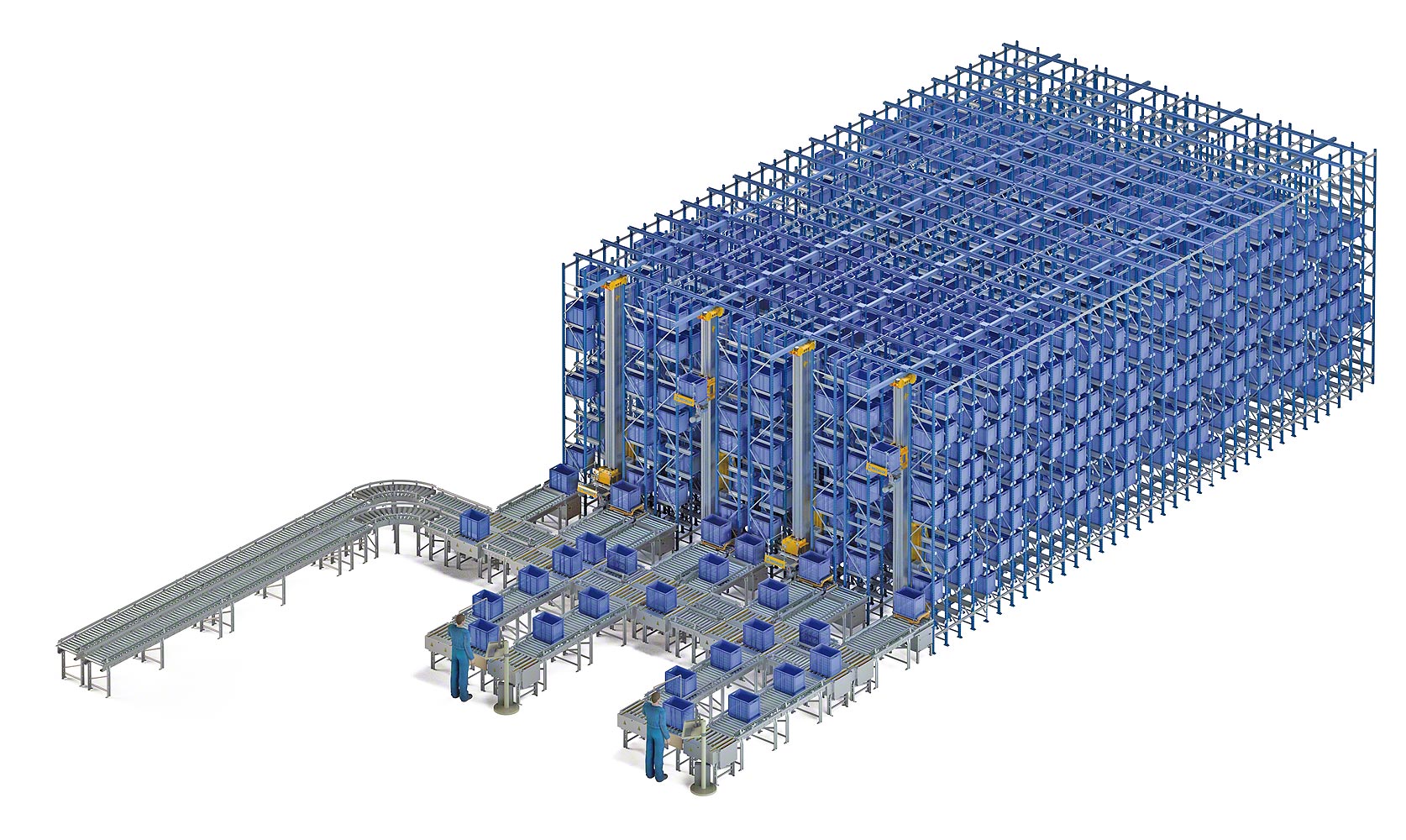

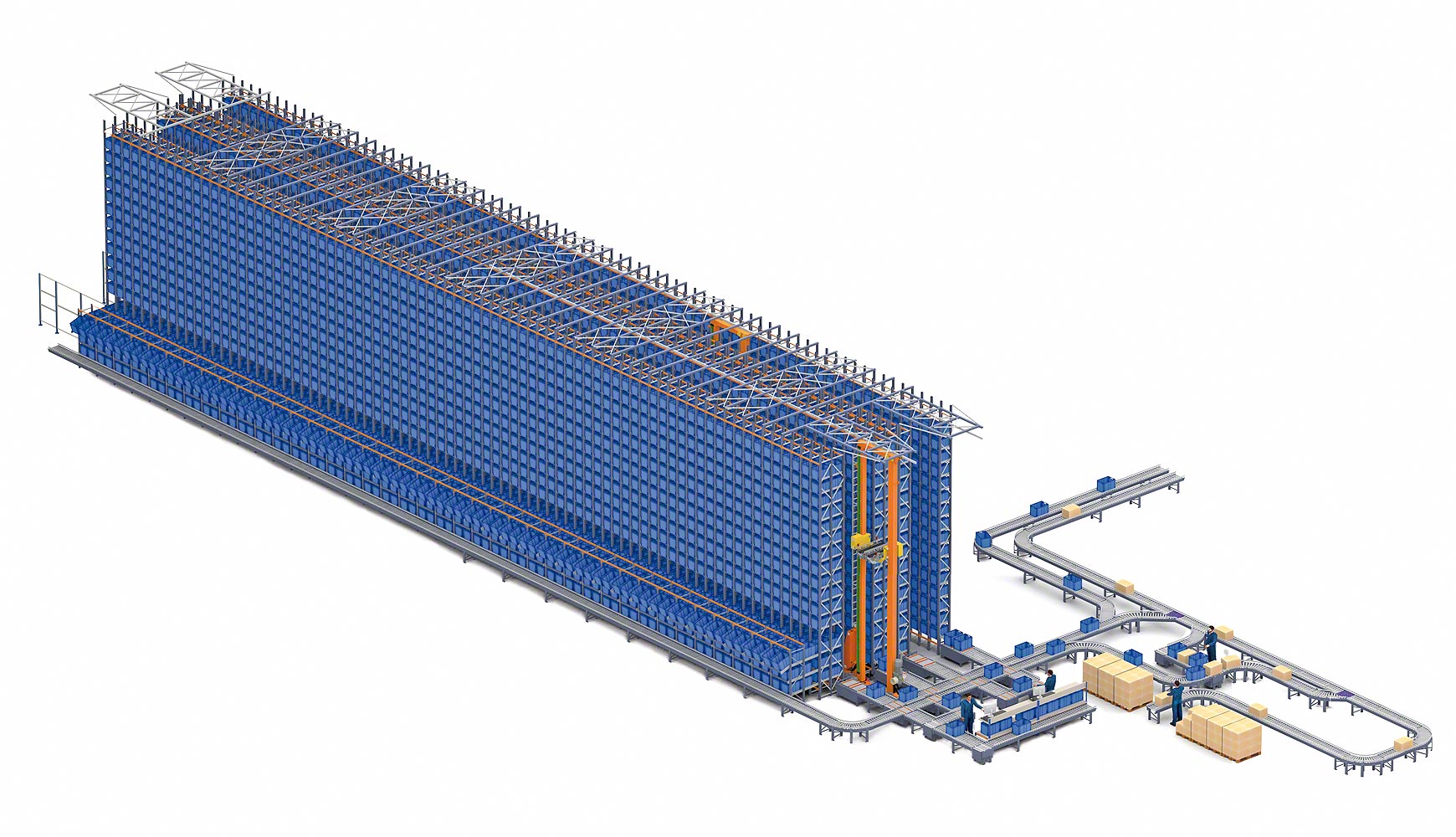

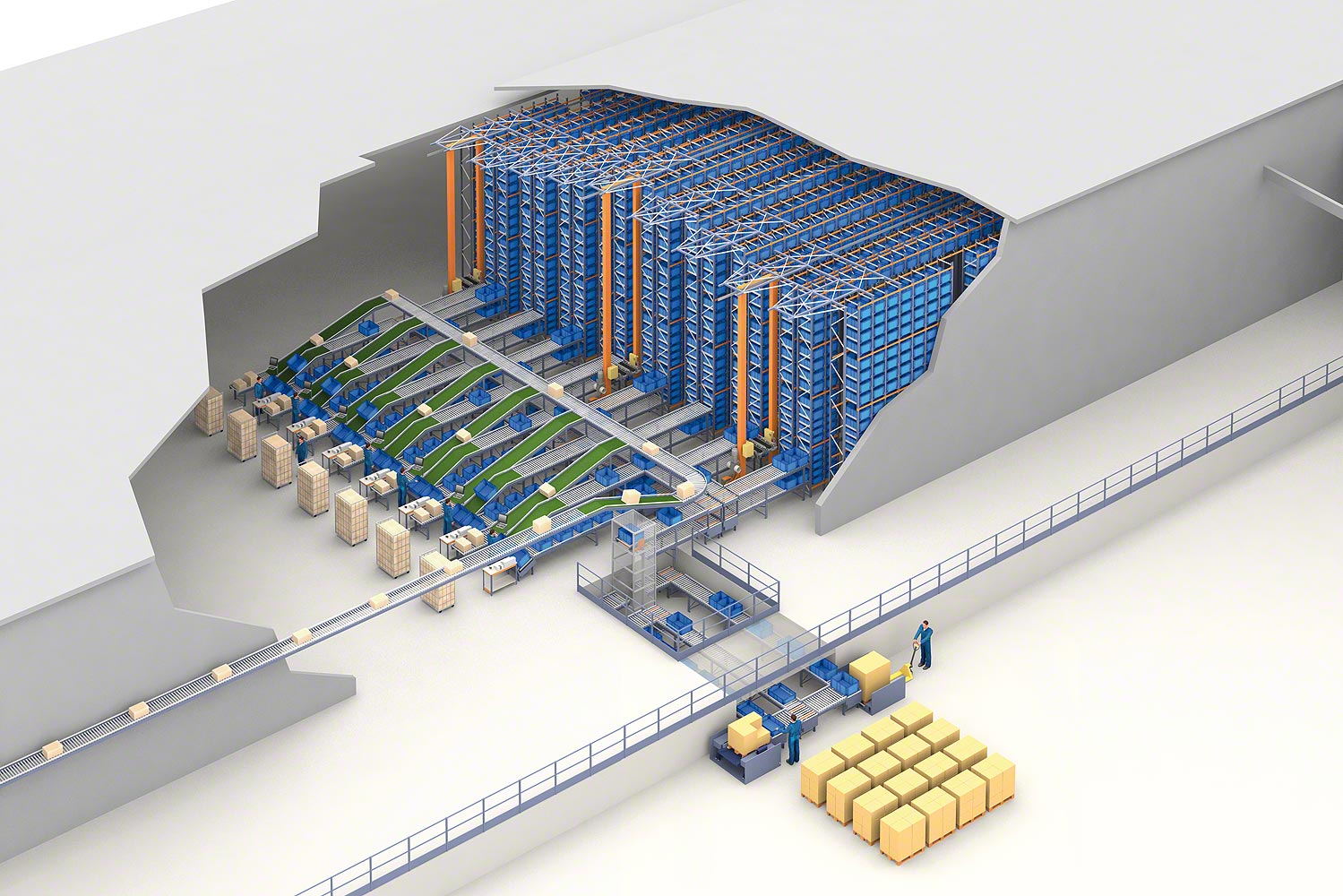

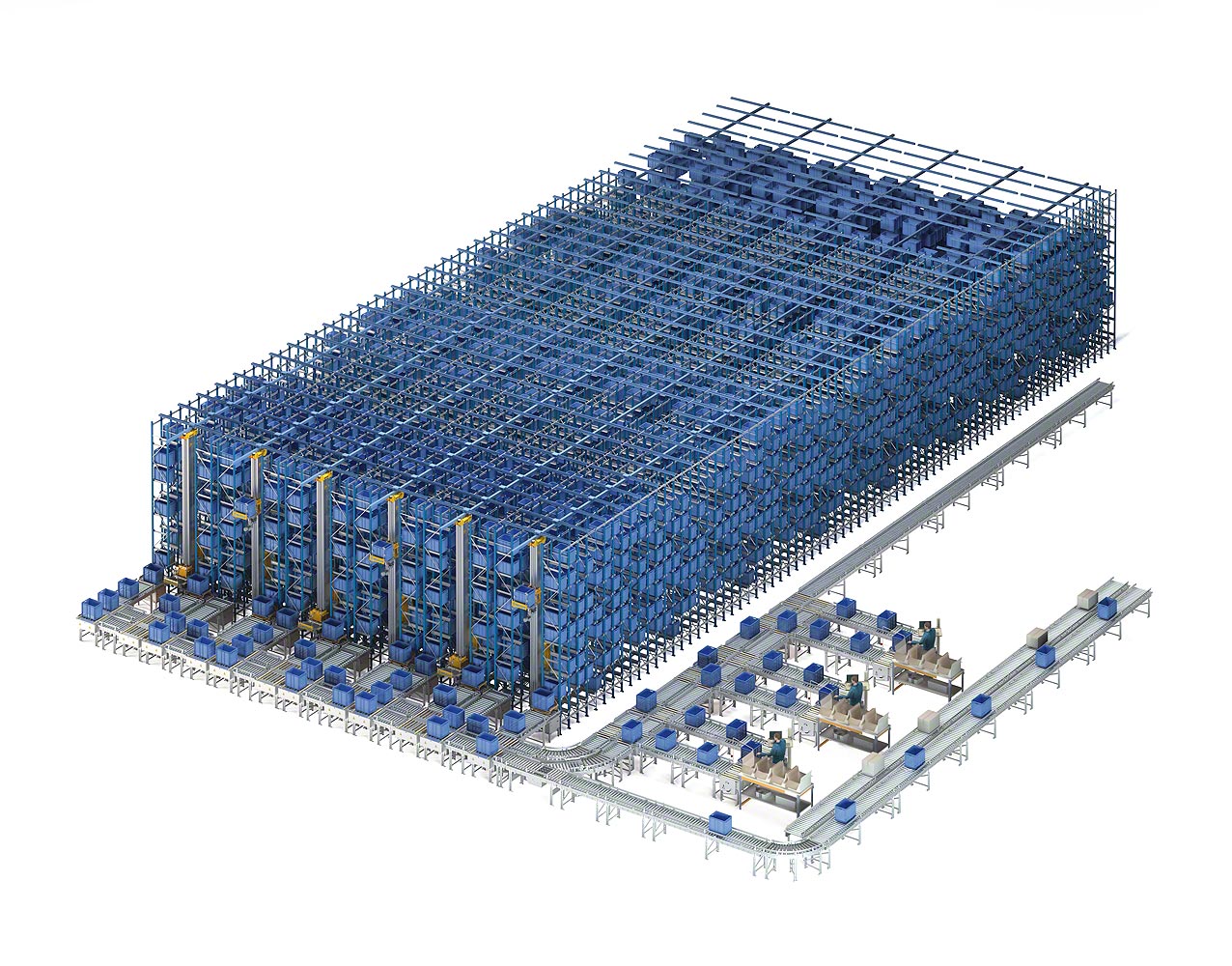

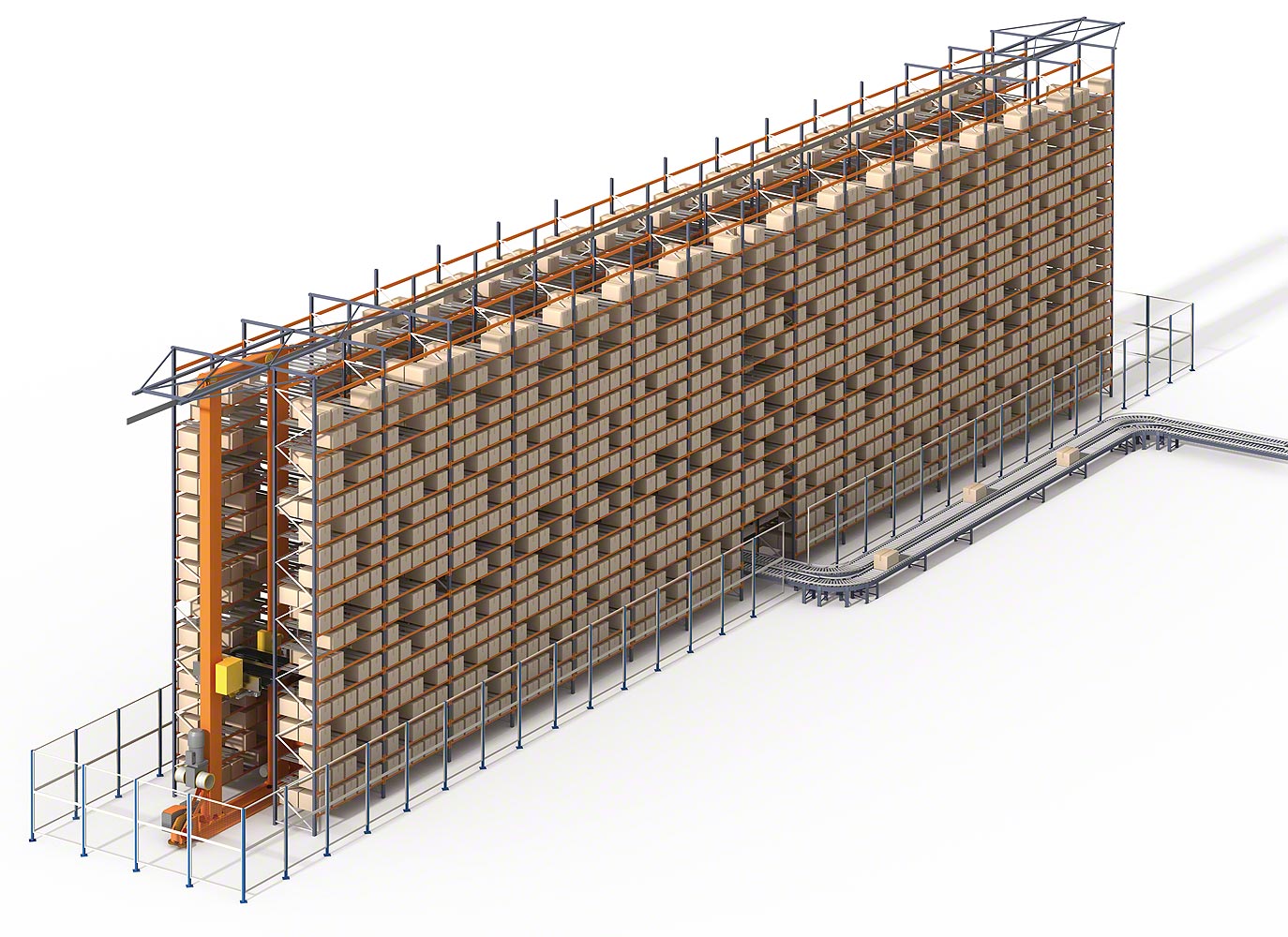

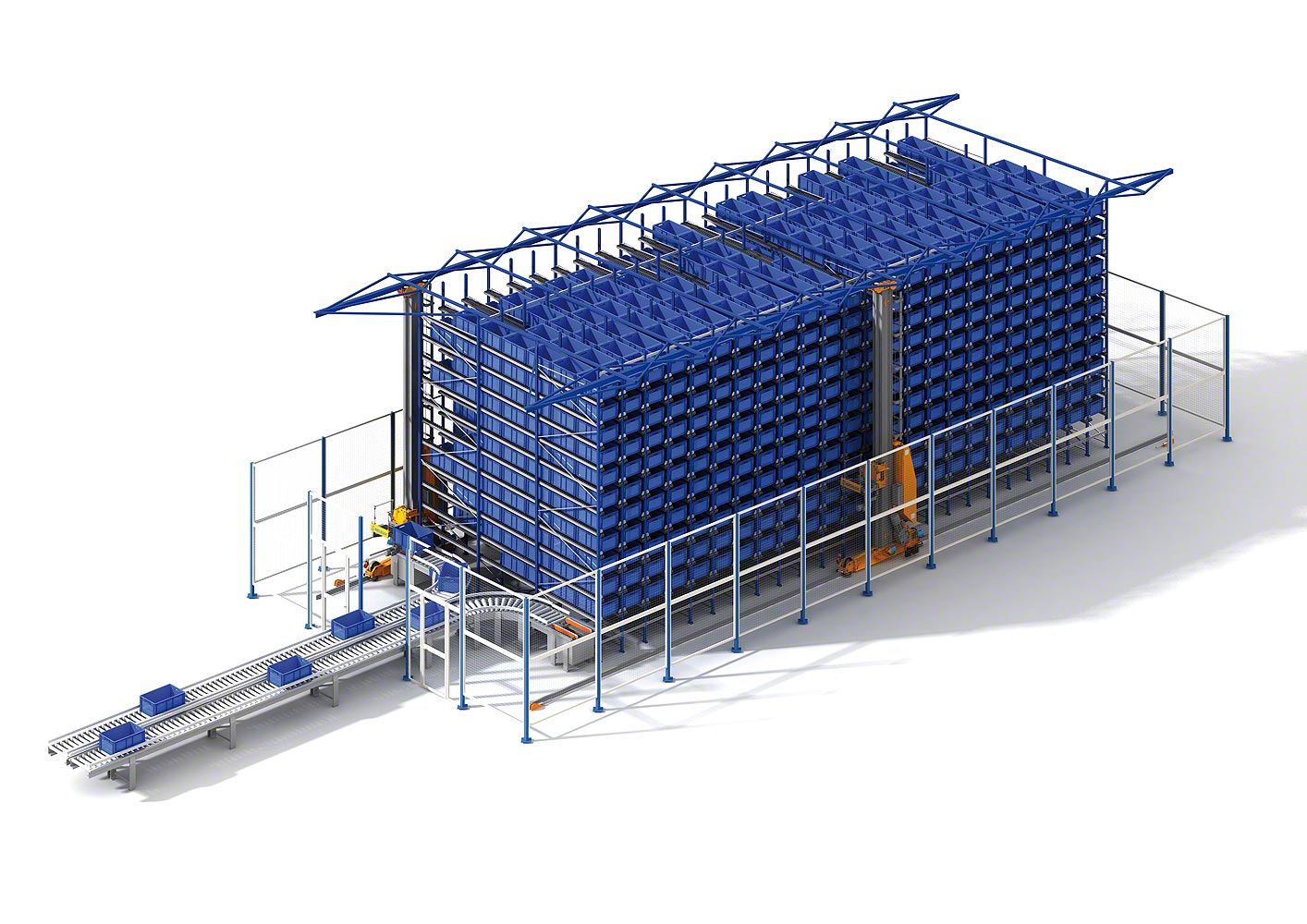

Mini-Load Systems (AS/RS for Boxes)

Automated storage and retrieval system designed for boxes, totes or trays.

This miniload system offers extraordinary versatility, and can be integrated into any production or storage system.

12ba1041-4cb2-c613-24d2-4c75246b83ed

2e3730a9-499b-b0ac-f65b-f4f18fb4f607

1a7280d0-5204-d458-8e5c-1308c61b530c

a686c8c3-cb14-ea2c-b90a-e5e5842979d5

315ee82c-6f3f-3382-7a16-9ca3fbfad6f9

af6c93aa-deba-d9b5-70da-fad130d09a00

136a51b6-69d5-d50c-fda5-bd0f9fddc535

897af267-acb5-c7ce-a25d-f74bd755e7ee

67211507-2785-4ac5-da09-44e71b03355b

20aceaa8-5a74-dd89-f25f-fe466c230fb4

cd59ef18-a31c-e78e-9b89-79b63d38ee5b

fd0d4f23-8ae6-4f90-0234-f2700c64e16e

ea67c556-f994-af07-67cc-dabe61419824

02a830df-f093-4edb-7389-729e2a3039b4

e56526ea-4b6c-6bc7-7e2e-a1d34d4aa056

18874552-fd08-e33e-1e20-fd6b07e0a4e7

b08f5409-497c-8eaa-3f7a-653f9e6523b1

880ebde2-8b97-b421-6e7b-fd2f06c1eba3

94e0177c-f43b-3a9b-3ec4-7d60255d3036

55073640-f756-a11e-e350-1b406bb3fe02

658aefc2-6d7c-caf7-439e-0d9889f6aad6

d9bb15ef-4f15-69cc-a7f0-ff38aa5f301d

b4fe34a8-7094-c1e7-6a48-74cc7a0be2f8

2b7c1667-6489-2442-1348-aab2cd174ea2

7e7c5164-67e9-08e6-04e6-e4f5894bf928

53574132-612f-1162-b2d6-f3db1a886dca

4d7288b7-d0cb-beea-f87b-e525178febe9

b08f1e56-30e2-e7bd-680d-e036e71ca8b2

1af83852-c329-1d41-7553-8f7c61876f6d

c96f41ec-9e82-6c17-5fd7-44aede580a1f

c05f95da-7220-7515-ee1a-cccb610fca1c

31d3451f-47cc-4618-d712-6c851a167656

5228ff96-2701-6083-a1ec-9d5dcc55d4f7

fc8ed309-5f82-96fe-fb20-4cc21e623fad

dd2b40dc-9ee2-77c1-345f-0e784364a8ec

23eb636e-a9bf-e0db-b943-69d56d81124d

7593da69-0296-f0db-dd19-5de37f677f99

ff4768bf-6cb8-113e-4101-0441c47d8664

ee8d63c7-1082-e4fb-08d4-5ccad050a8f4

511f6e13-5d32-8957-cfe2-9e1975c9cacd

cec08ea7-204d-511a-7aa0-1c0d9934f816

da3f601f-9bdc-2857-a722-d1753b6291a5

2b80c40e-5b1e-8747-ebfd-952e238a44b8

1839b6ff-226d-a025-1721-b722b6782b03

2eb306d6-22d3-137b-7083-e9c92fc91d4b

6a60a8b9-8714-2872-0c38-5a2317490c03

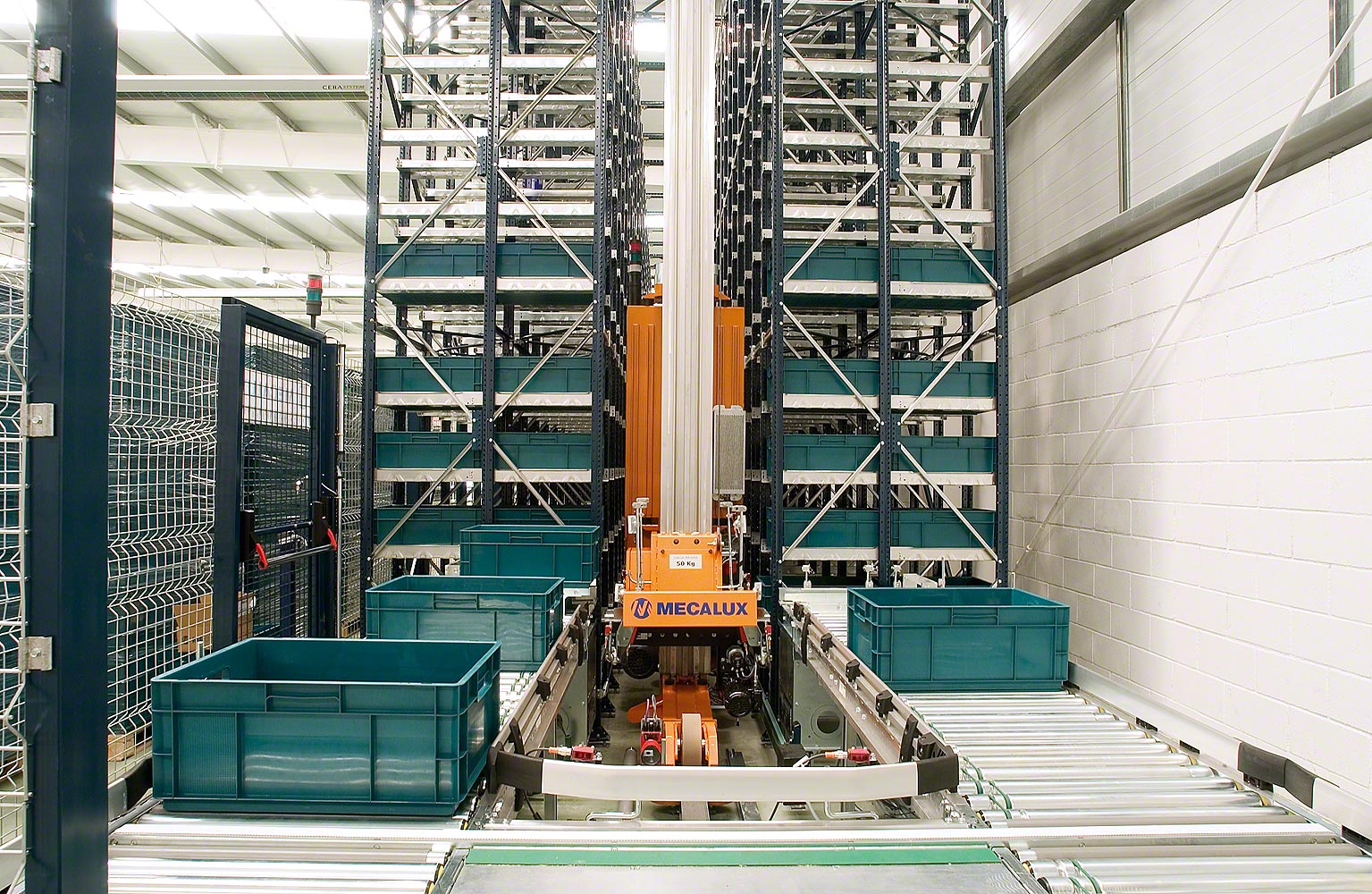

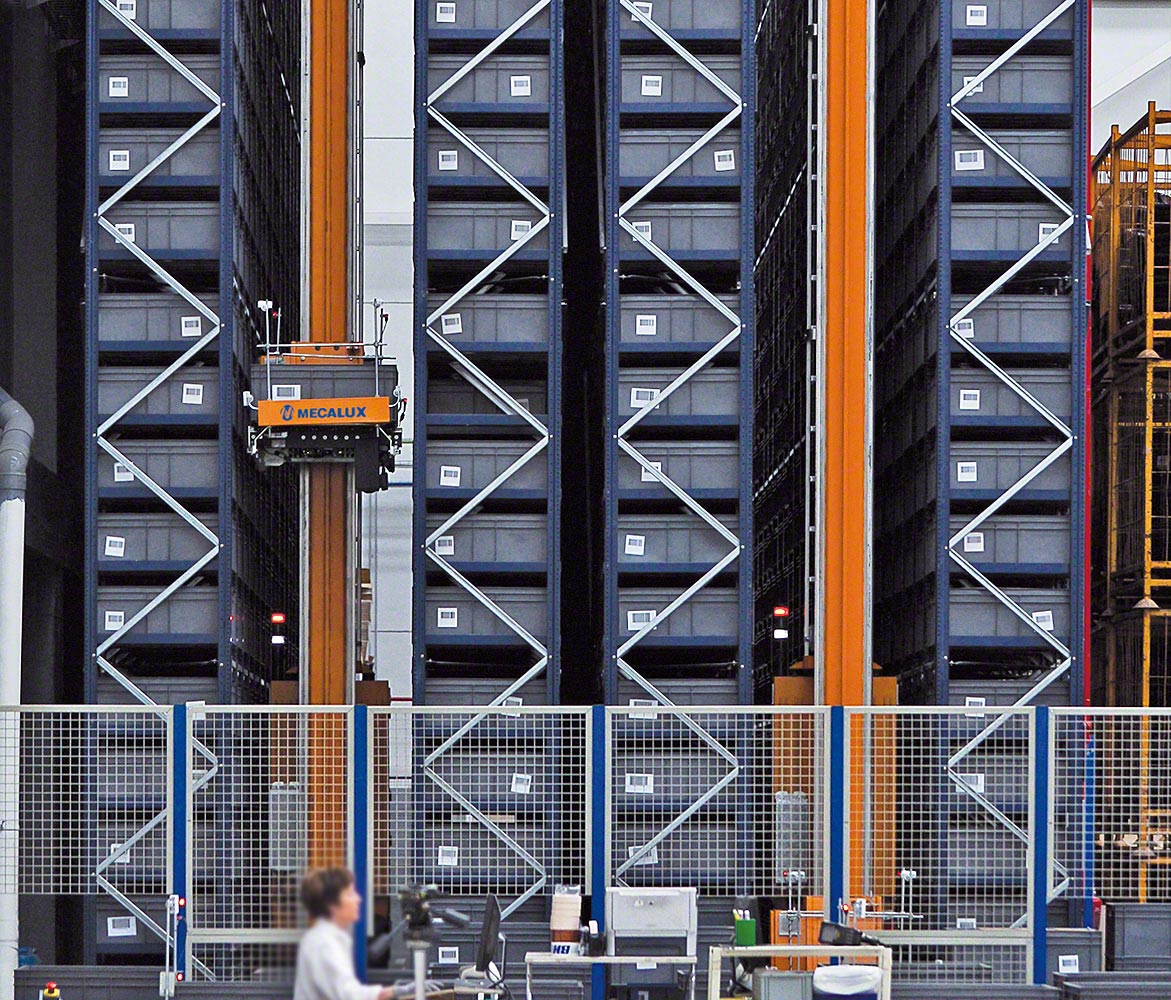

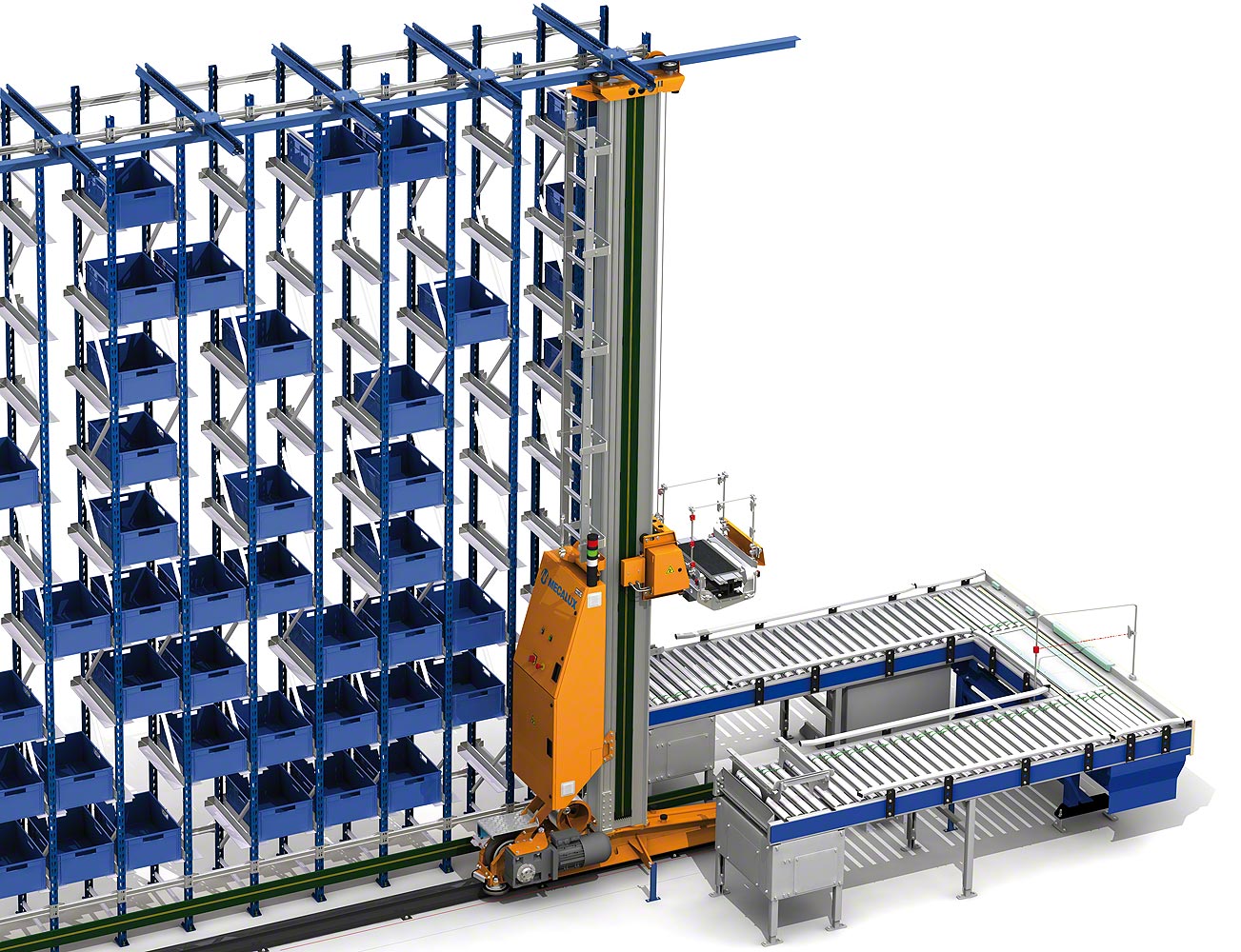

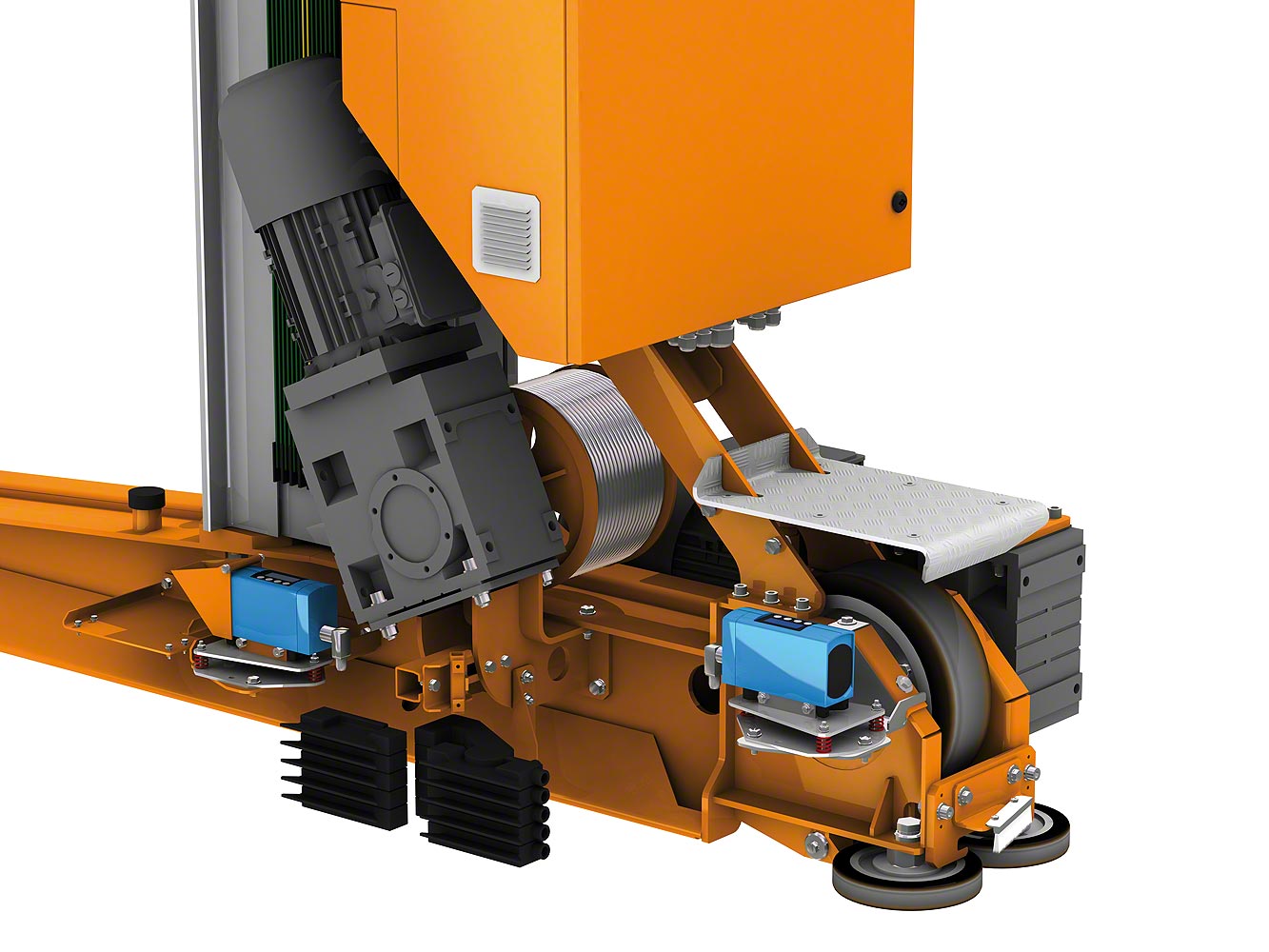

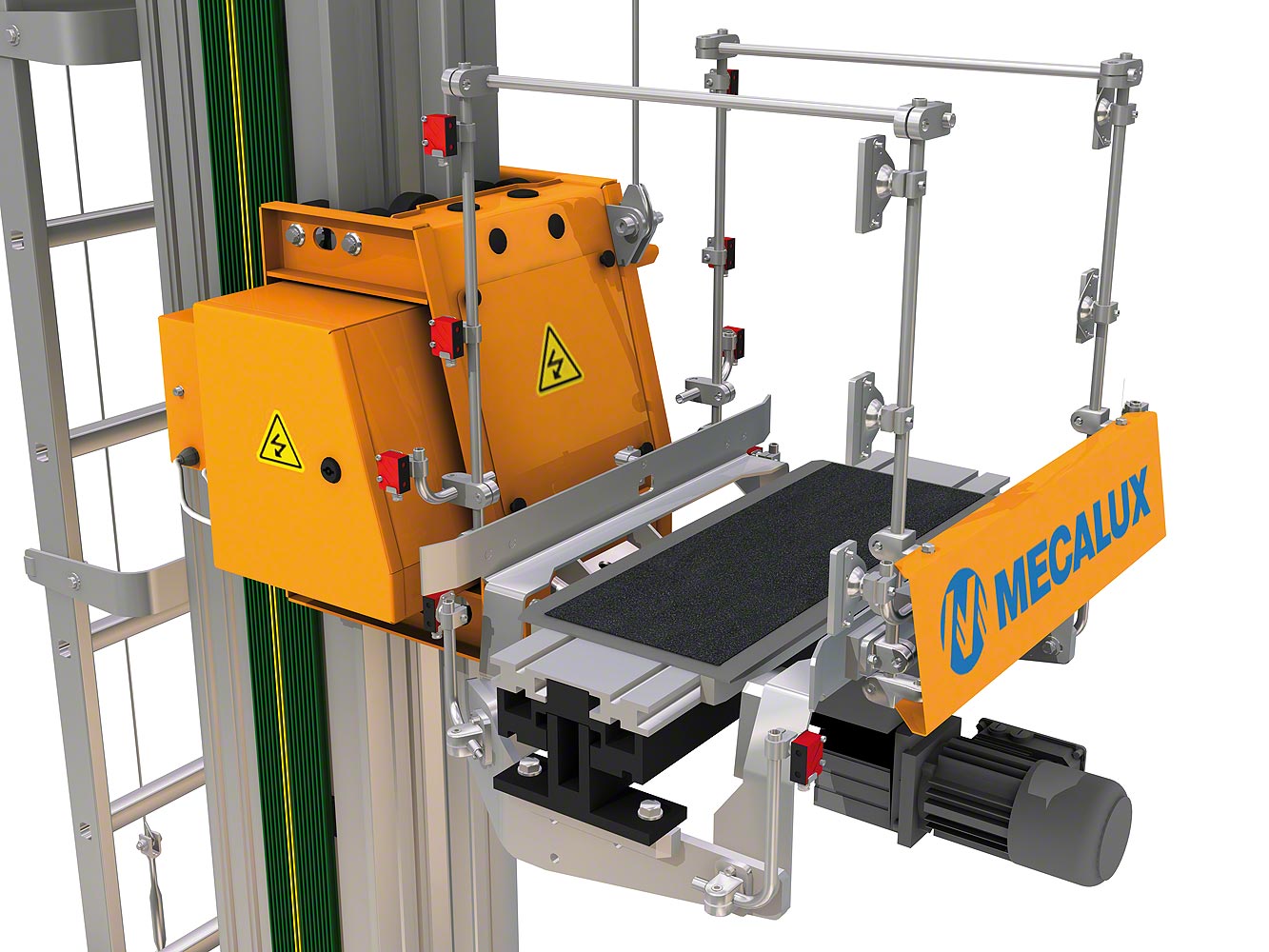

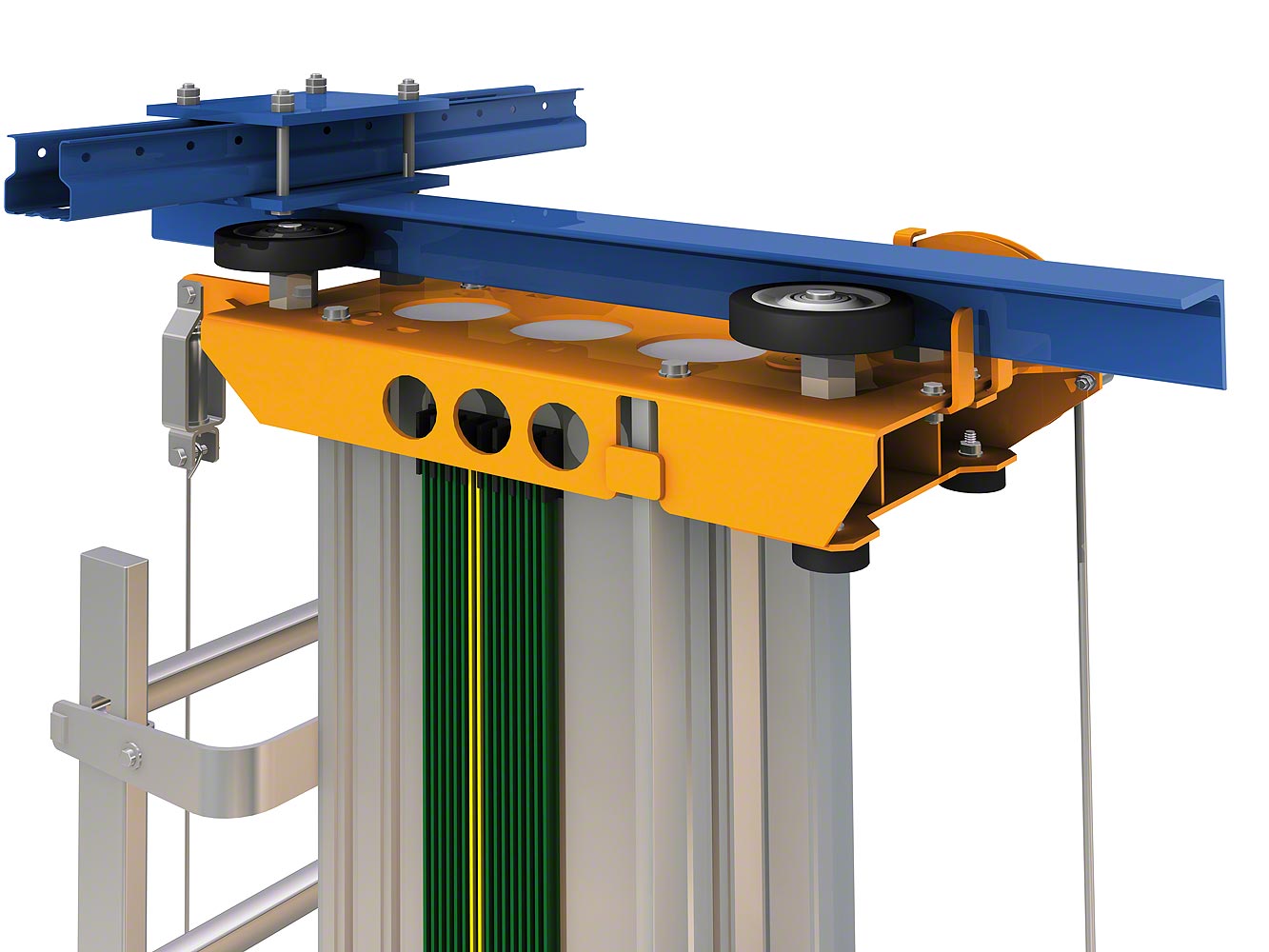

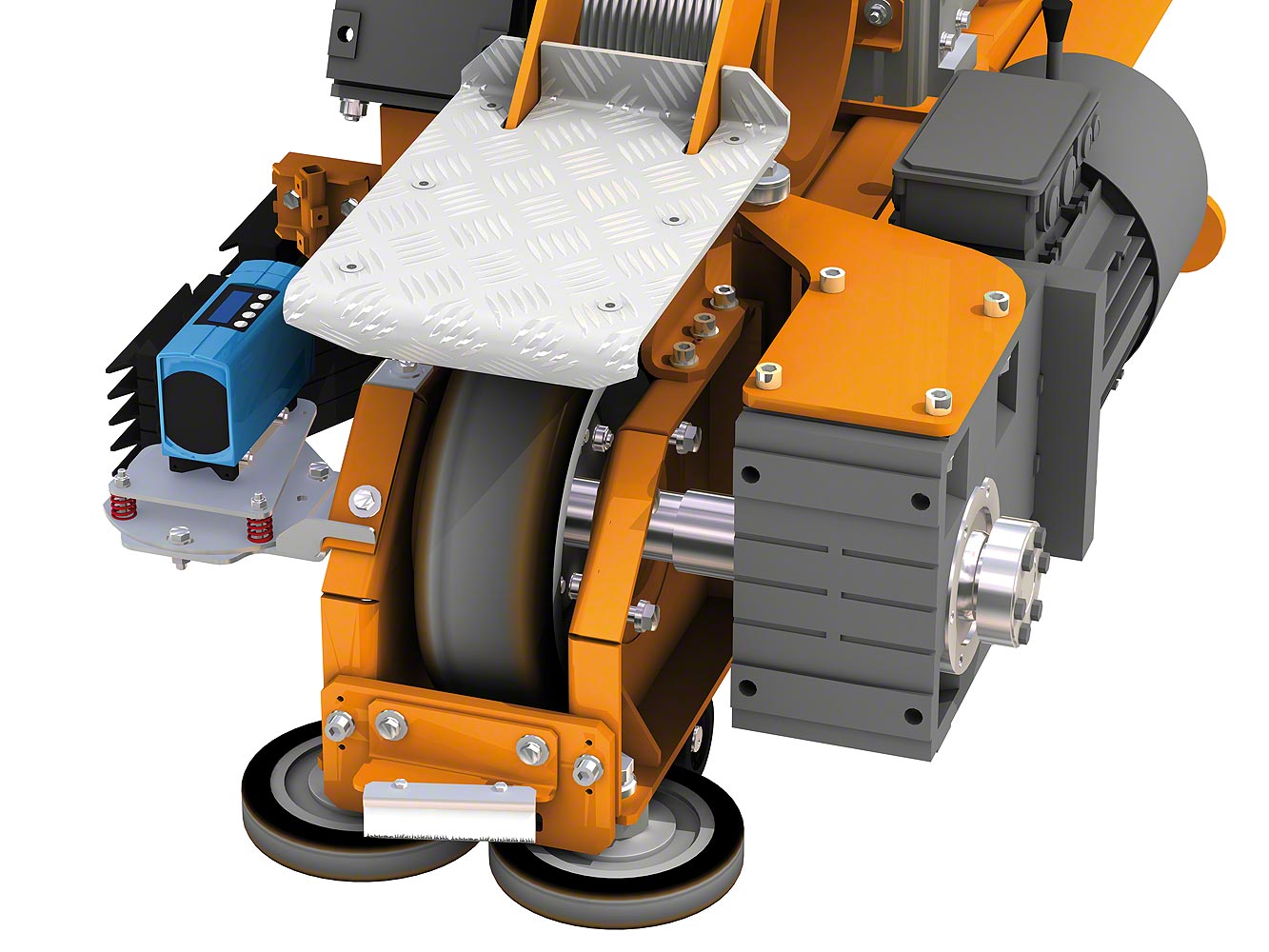

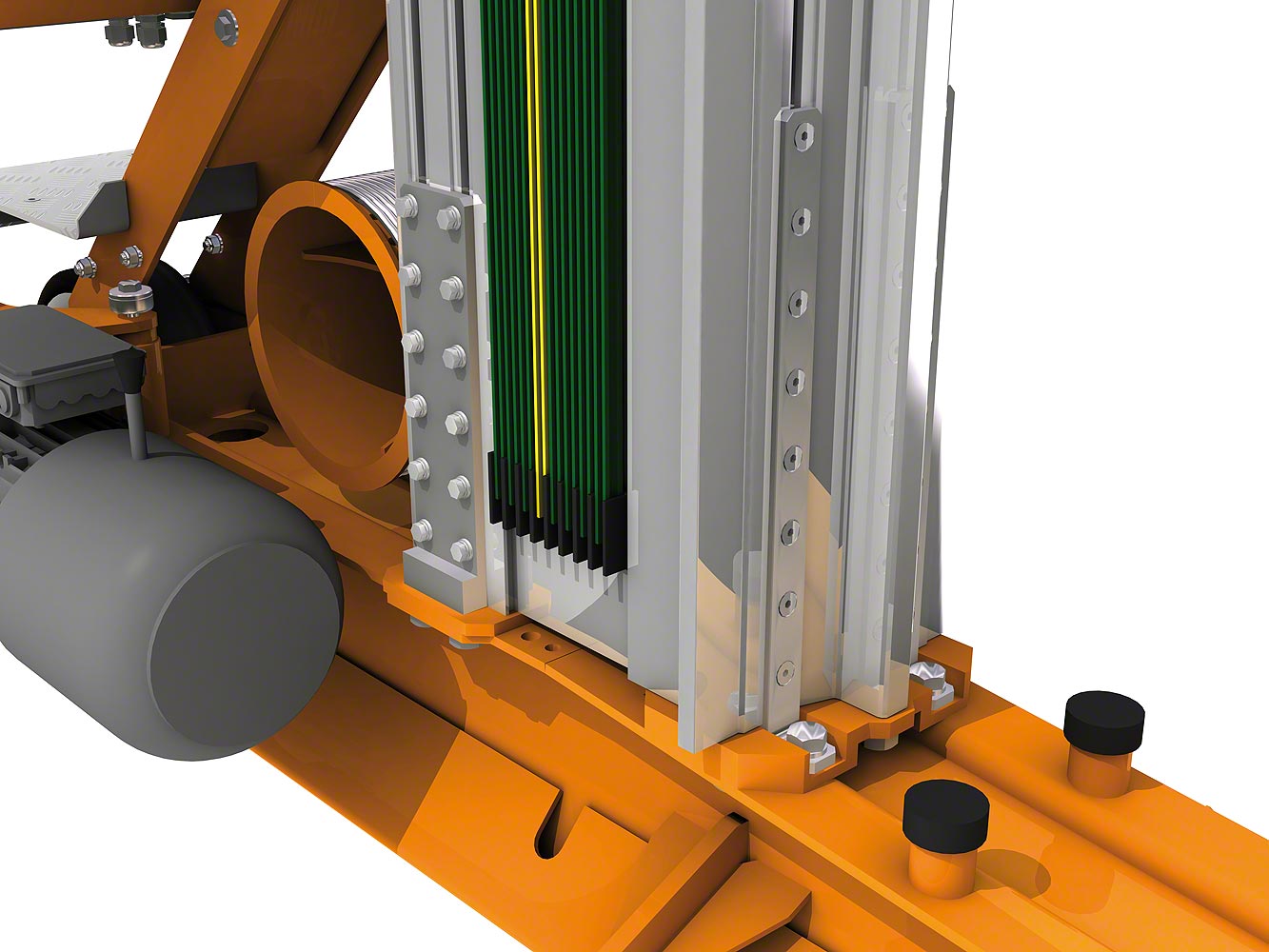

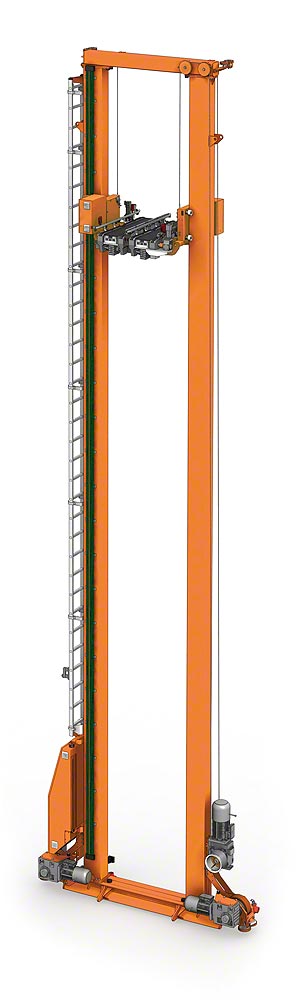

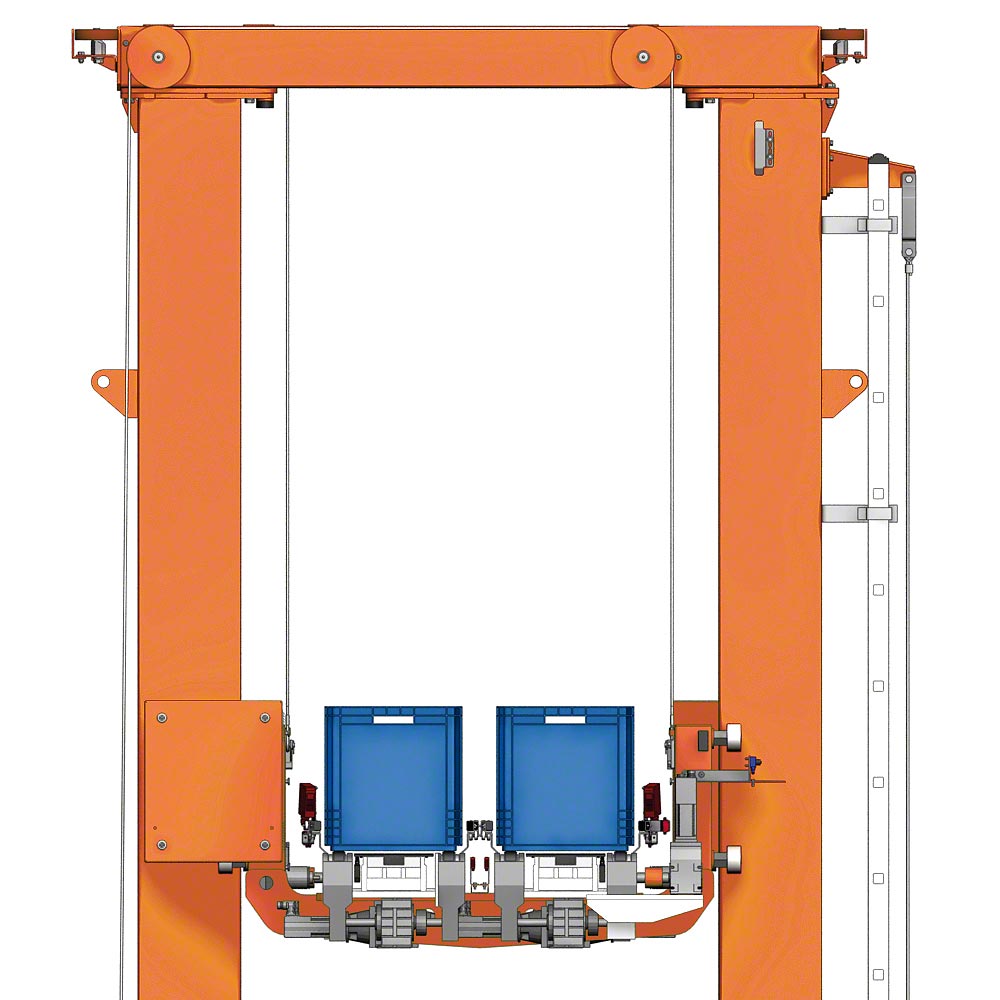

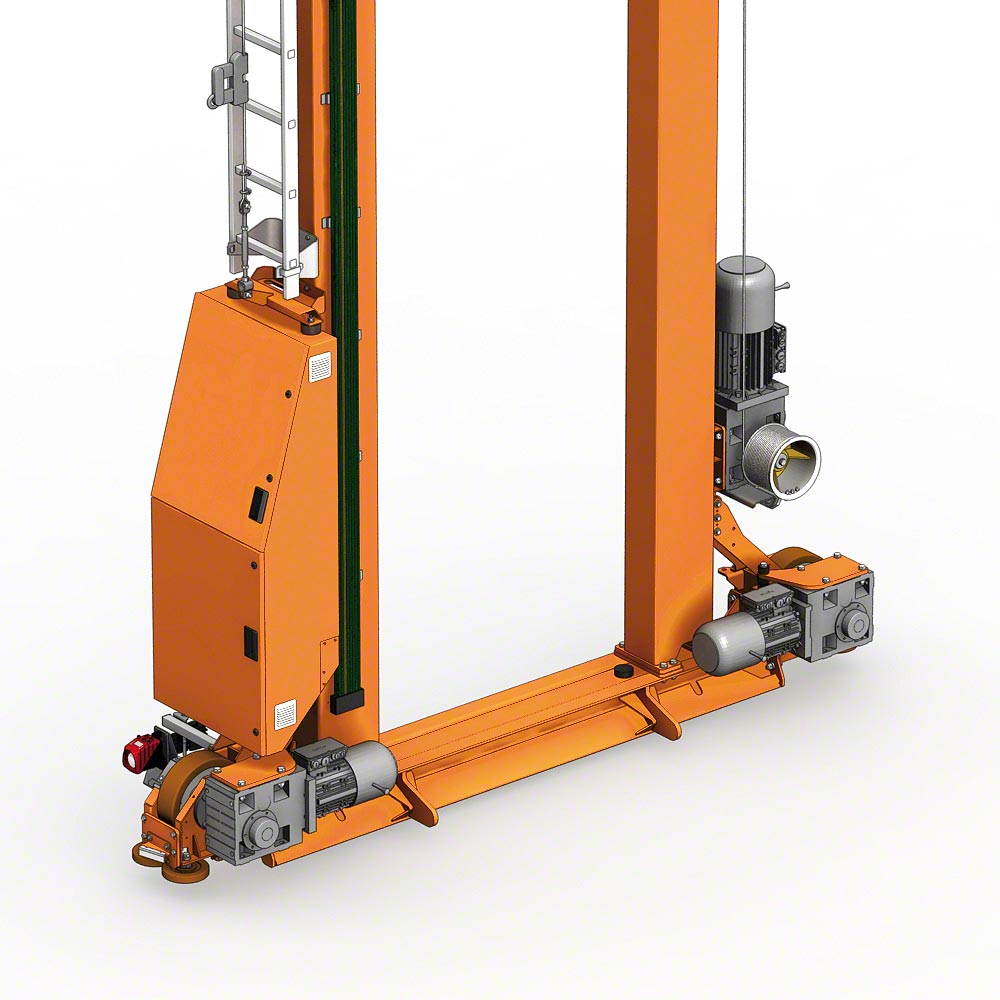

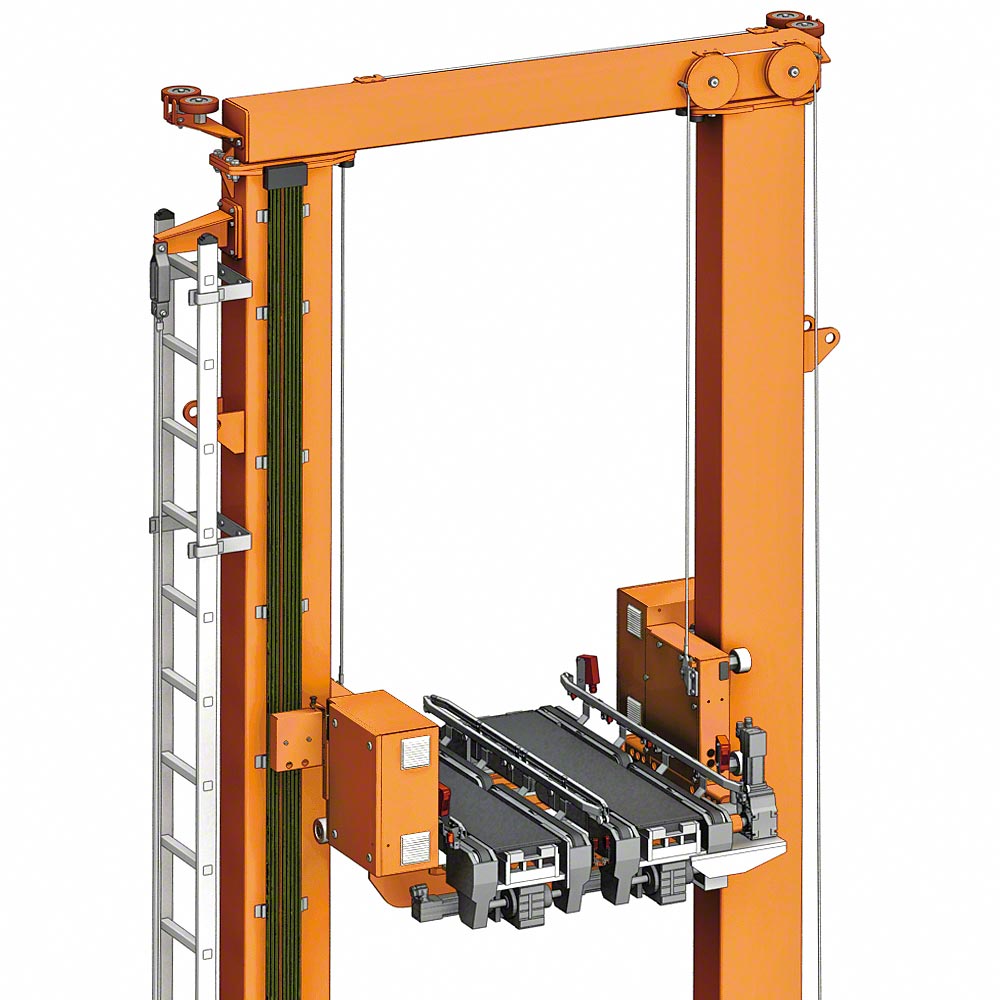

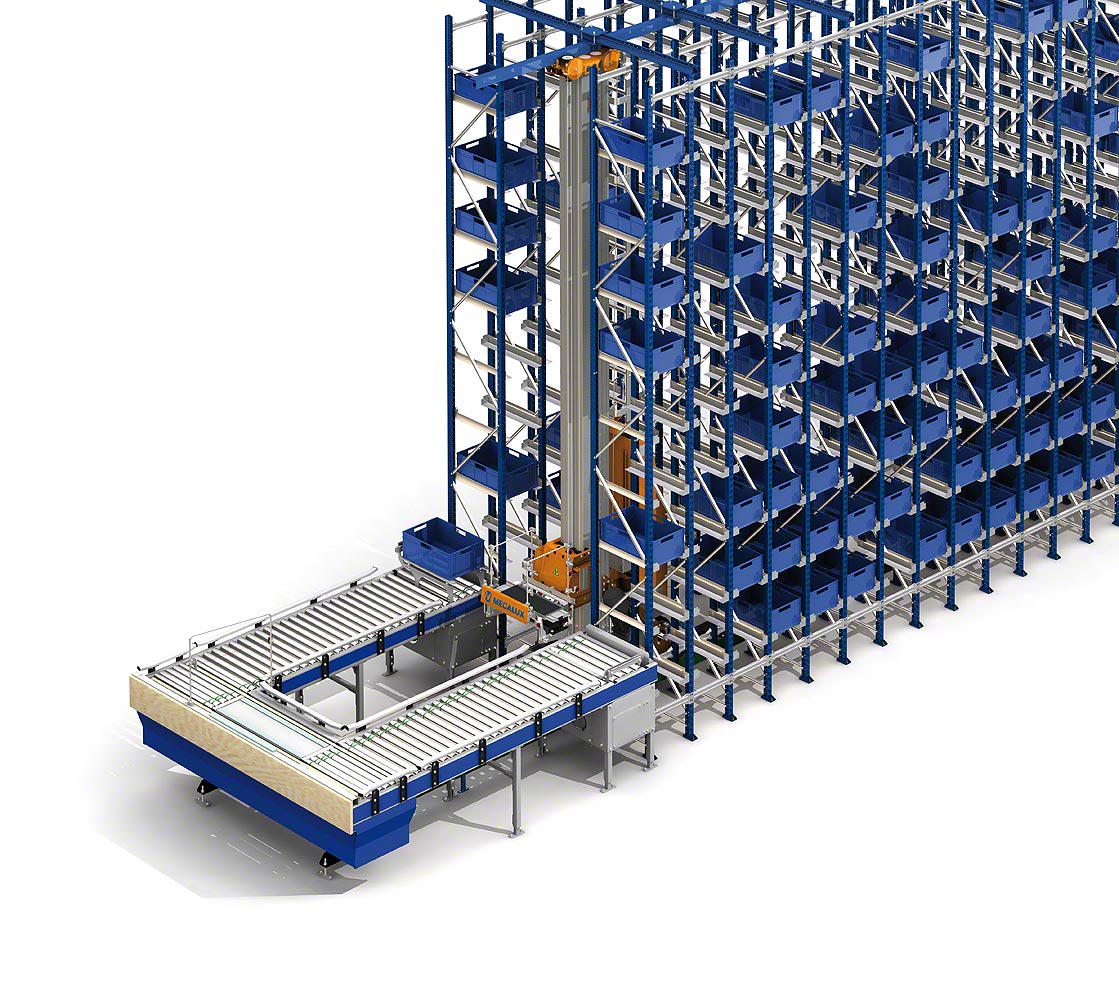

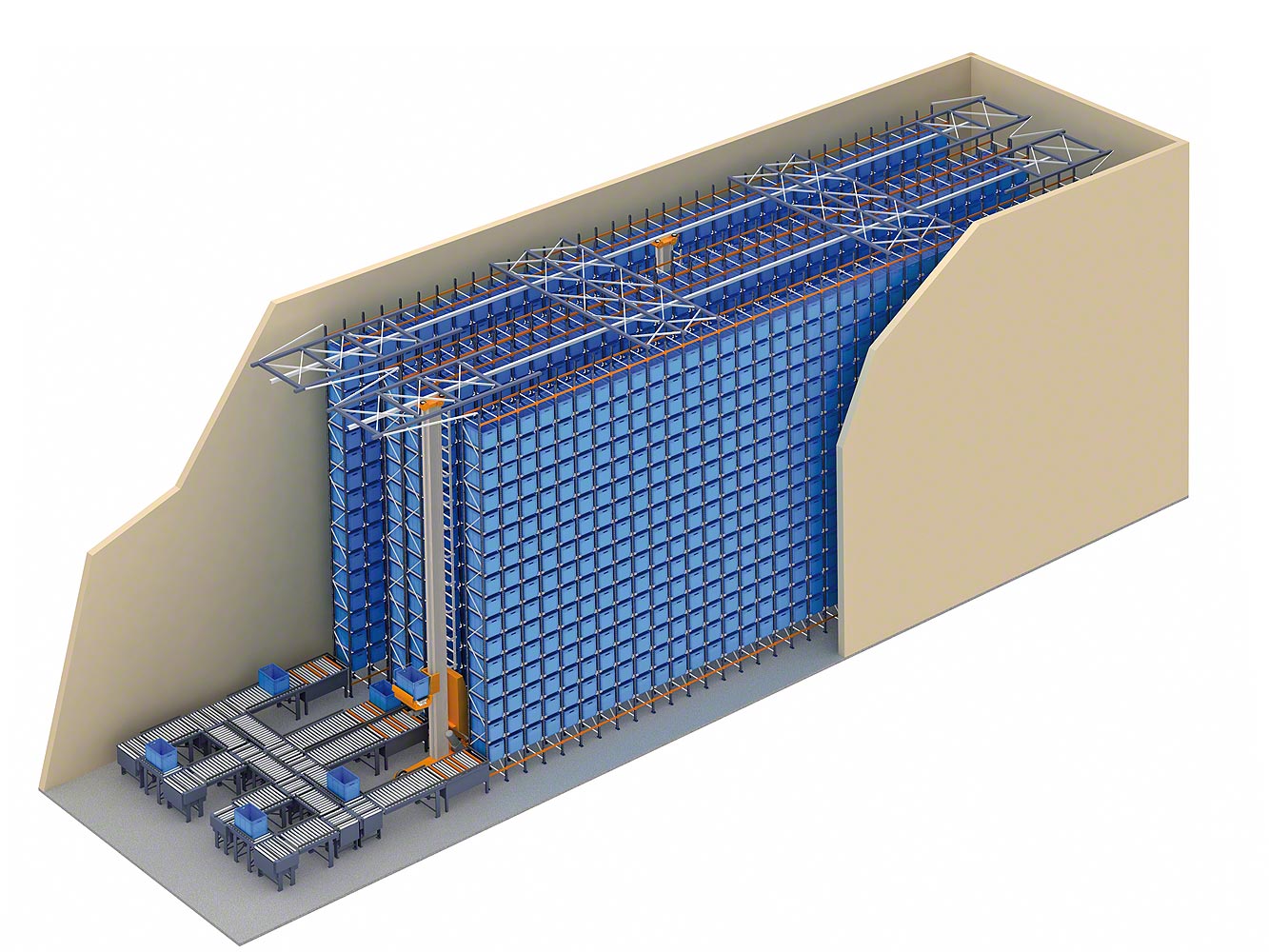

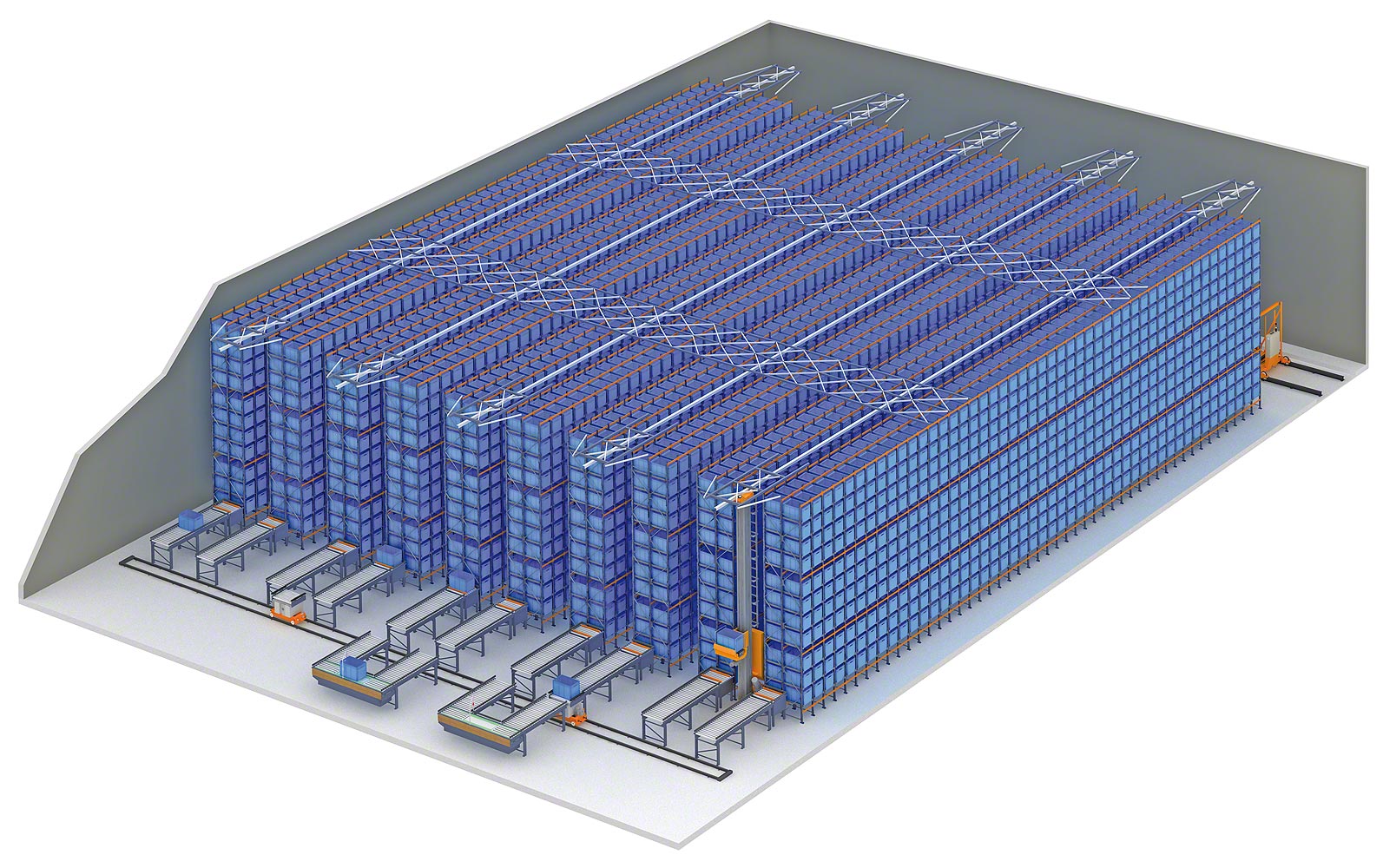

The Mini Load automated warehouse for boxes is an extremely dense storage system designed to move at high speeds for increased productivity in a compact footprint. Utilizing stacker cranes, the mini load system has a standard horizontal speed of 590 feet per minute and a standard vertical lifting speed of 328 feet per minute which improves picking times and operator efficiency.

The mini load system is primarily used for the storage, movement and order fulfillment of small or irregular goods in boxes. In addition to providing the optimum method for handling pick boxes, it is also designed with the basic ergonomic and safety equipment need to perform work and maintenance operations as simply as possible.

Advantages

- Easily expandable system which can be quickly dismantled and reassembled.

- Increases safety by reducing operator fatigue.

- Stacker cranes maximize capacity and increase throughput while operating smoothly and quietly.

Whether selecting the automated warehouse IN-A-BOX or fully customizing a product for specific storage needs, the Interlake Mecalux Mini Load AS/RS has the versatility and functionality desired in an automated warehouse. With three operating modes, fully automated, semi-automated, or manual, and a warehouse management software designed to be user-friendly, training on the system is simple. Although plastic boxes (totes) are used most often, the system is compatible with metal containers, plastic trays, collapsible totes or cardboard cases/boxes.

Ask an expert