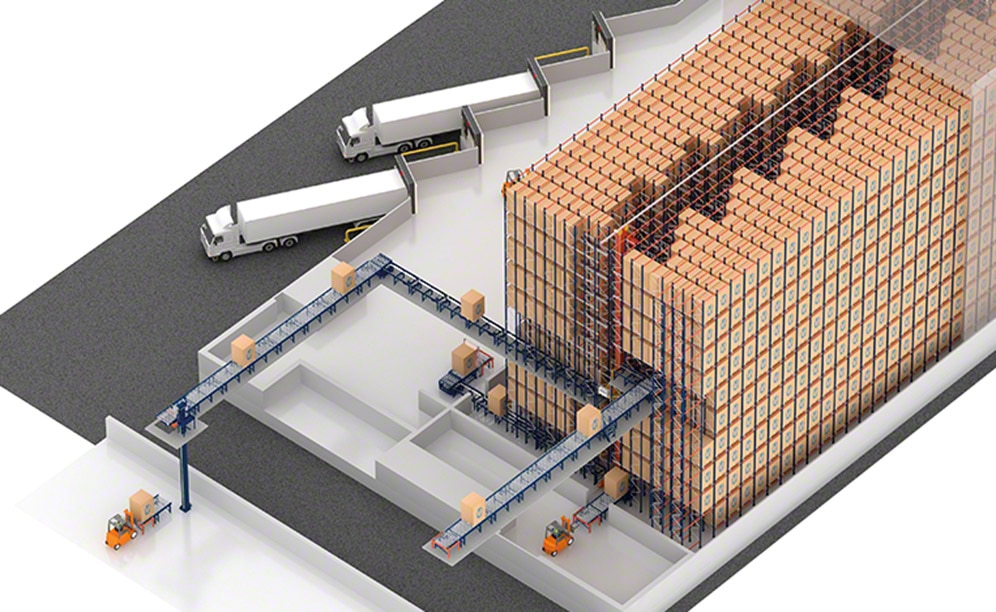

The AlzChem chemical company will build a new 82' high automated warehouse run by the automatic Pallet Shuttle system. Overall, the warehousing capacity will exceed 5,000 pallets. The company will deploy the Easy WMS, a powerful warehouse management system (WMS) developed by Interlake Mecalux, to guide the operations of such a large project.

The warehouse will include a single-aisle run by a combined stacker crane-Pallet Shuttle system. Two installed blocks of racks, either 33' and 36' deep, will accommodate between seven and eight pallets per channel. The warehouse will be linked to the production building via a conveyor circuit that will move raw materials. End product will flow straight back to the warehouse installation by means of a second conveyor.

The Interlake Mecalux WMS will stage an organized input and output of the goods, and assign locations to the pallets. The constant, two-way communication between the Easy WMS and the AlzChem ERP means better productivity in this logistics center.

Andreas Hensel - Materials Manager at AlzChem

“Mecalux caught our attention with its competitive project proposal. Now, we run 24/7 and do it completely operator-free during the night shift.”

About AlzChem

AlzChem Group AG is a vertically integrated business that manufactures nitrogen-carbon-nitrogen (NCN) based fine chemicals used in a full gamut of industries. The company is a niche market leader in products like food additives and nutritional supplements. Currently, it has more than 1,500 employees, as well as four production plants in Germany and three abroad.