Rica Group opens the Dominican Republic’s first pallet AS/RS

A leading producer and distributor of dairy products, juices, and food boosts logistics productivity by 35% with Mecalux technological solutions.

Rica Group drives its logistics operations with an automated storage and retrieval system (AS/RS) from Mecalux, doubling its export capacity and increasing productivity by 35%. Automation ensures an efficient flow of goods, reduces costs, and enables accurate inventory control with real-time traceability.

Rica Group: Over 58 years of experience

Renowned for its commitment to quality and innovation, Rica Group has become a trusted brand for millions of consumers in the Dominican Republic. The company operates six distribution centers that supply a wide network of grocery stores — its main sales channel — as well as supermarkets. Founded in 1966, Rica Group is present in over 22 countries.

CHALLENGES

|

SOLUTIONS

|

BENEFITS

|

|---|

“Logistics automation is crucial for achieving operational excellence, delivering high-quality products, and building a faster, more efficient supply chain.” Alejandro Rojas, Logistics Director at Rica Group, underscores the importance of the new automated storage and retrieval system (AS/RS) from Mecalux at the company’s Santo Domingo headquarters. This AS/RS — the first of its kind in the Dominican Republic — marks a national milestone. It will enable Rica Group to double its export capacity in the coming years and strengthen its presence in more than 22 countries.

To meet growing demand, the business has made strategic investments in the past few years to optimize its milk and juice production capabilities. More recently, it has shifted its focus to logistics, consolidating products previously distributed from multiple warehouses into a single facility. Through automation, it has increased its logistics productivity by 35%.

“As part of our commitment to innovation, we’ve implemented the Automated Pallet Shuttle system. This AS/RS has maximized space utilization and quadrupled our storage capacity without expanding the facility,” says Rojas. Centralizing its logistics operations has enabled Rica Group to gain stricter control over its processes and SKUs, lower operating costs, and provide faster, more efficient customer service.

According to Rojas, when selecting a supplier to install the Dominican Republic’s first AS/RS, the decision was clear. “We chose Mecalux as our strategic partner because of its leadership in warehouse automation technology, strong presence in Latin America, and extensive experience across a range of industries.”

The new automated warehouse is fully integrated into Rica Group’s production process. The company’s Santo Domingo facility holds FDA Grade A certification, ensuring compliance with stringent food safety and quality standards. This accreditation is essential for exporting dairy products to the US market.

Uninterrupted product flow

Automation is the ideal solution for the major challenges facing Rica Group’s food logistics operations; it enables the continuous movement of goods and accurate traceability of perishable items.

“Mecalux’s comprehensive solution ensures a steady and efficient product flow, minimizes disruptions, and optimizes inventory management. It provides us with more rigorous control over our dairy products, juices, and food,” says Rojas. “These benefits have significantly boosted our production capacity.”

The new AS/RS can store and dispatch up to 120 pallets per hour. Before its implementation, managing that same volume took three hours — highlighting a remarkable improvement in both speed and productivity. Automated conveyors installed along the front and side of the AS/RS feed pallets from production into the system without manual handling. This technology reduces physical strain on personnel and increases operational efficiency, streamlining the flow of goods.

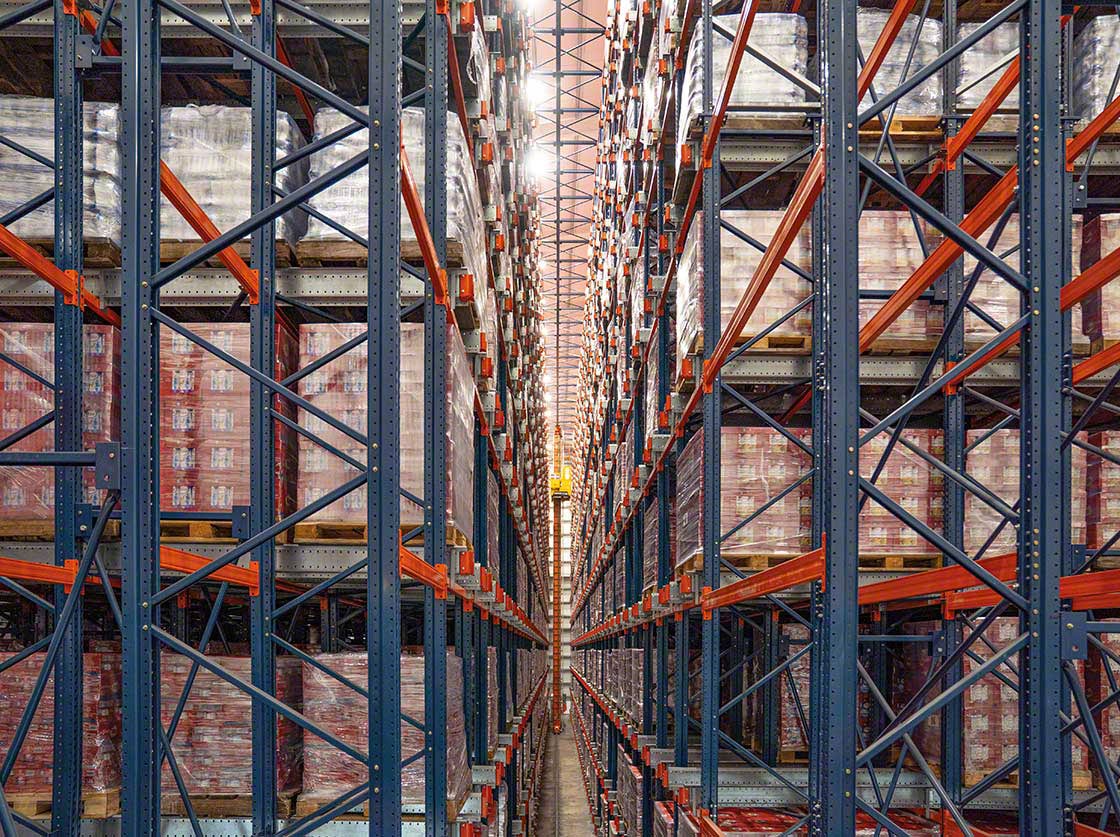

Rica Group’s Automated Pallet Shuttle system stands out for its compact, high-performance design. It combines efficiency and capacity across three 197-foot-long aisles with 69-foot-tall racking. The company can now store nearly 10,200 pallets in less than 21,527 ft².

Warehouse synced with production

Integrating Easy WMS with Rica Group’s ERP software has synchronized production and logistics in real time. Now, the warehouse management system identifies finished goods from the factory in advance, giving the company control over which products it will ship. “Digitalization guarantees strict inventory management based on weight, quality criteria, and expiration date,” says Rojas.

Pallet monitoring is vital for Rica Group’s logistics operations: “We have full traceability of our goods. We know at all times the number of SKUs, their location, quarantine period, and batch number,” says Rojas. Rica Group’s finished products undergo a thorough quality control process, making them fully suitable for consumption. During this process, items remain in quarantine until they pass inspection and are subsequently distributed.

When shipping goods, Easy WMS applies the FEFO (first expired, first out) inventory management strategy, prioritizing items with the nearest expiration dates. This method fosters stock turnover, reduces waste, and maintains product quality until delivery.

Centralized, interconnected logistics processes

“Thanks to our close collaboration with Mecalux, we’ve successfully designed and implemented a system that drives our logistics operations and growth,” says Rojas.

Rica Group’s new automated warehouse in Santo Domingo is a capital investment aimed at optimizing product distribution across the Dominican Republic, the Caribbean, and the US. Additionally, it will reinforce the company’s leadership in the regional food sector.

Mecalux’s comprehensive solution ensures a steady and efficient product flow, minimizes disruptions, and optimizes inventory management. It provides us with more rigorous control over our dairy products, juices, and food.

Gallery

Automation enables Rica Group to manage up to 120 pallets per hour

Ask an expert