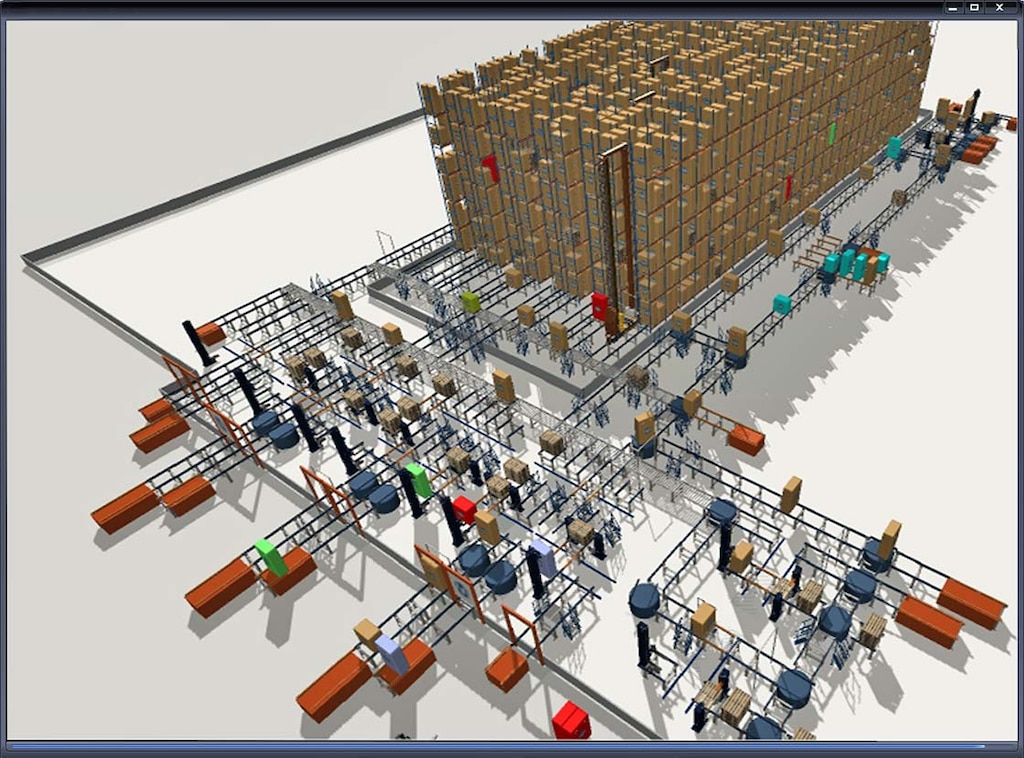

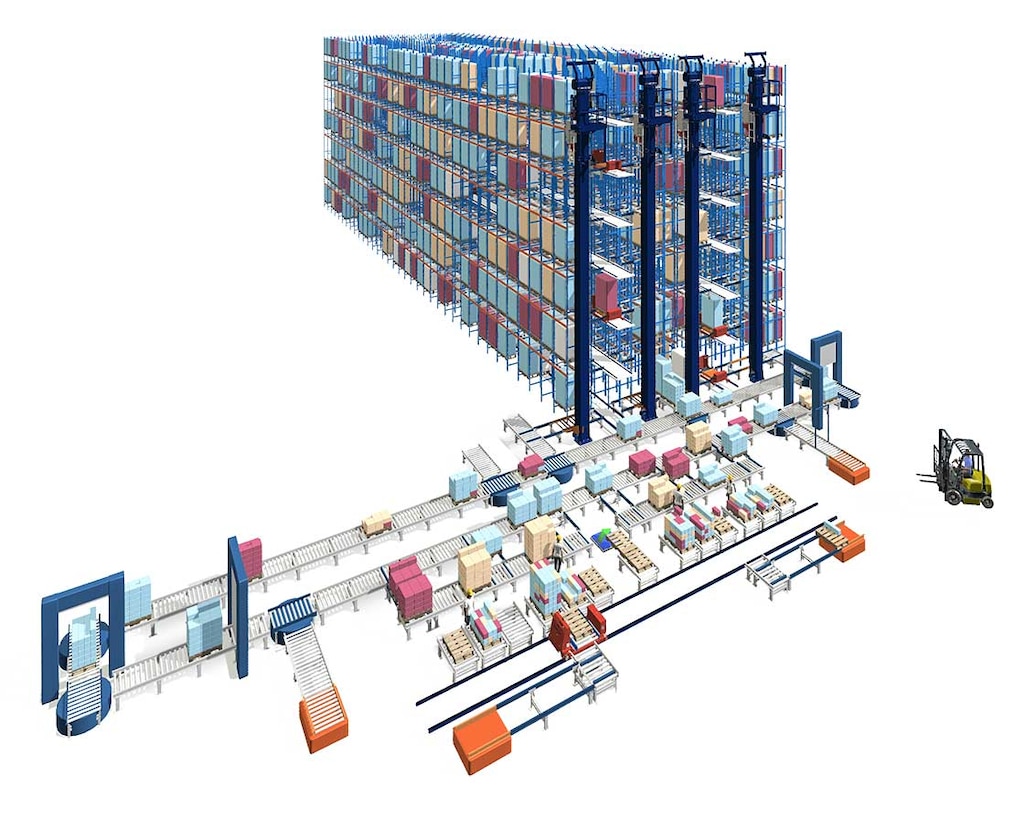

Simulation is a technological tool that enables companies to optimize their logistics facilities before commissioning them. Interlake Mecalux employs digital twins, virtual replicas that reproduce all processes and elements present in a warehouse: the goods, storage systems, automatic handling equipment, and software.

Interlake Mecalux uses simulation software to create virtual replicas of its clients’ warehouses and optimize operations

Interlake Mecalux’s simulation projects aim to predict the behavior of storage solutions in a virtual environment. They are carried out following a sequence designed to validate the facility’s future performance.

- Data collection. This phase defines the project scope and establishes the initial data that will feed the simulation model, e.g., current and expected goods flows.

- Solution design. Interlake Mecalux runs the warehouse simulation, testing different configurations in a virtual environment to ensure that the chosen systems meet the client’s objectives.

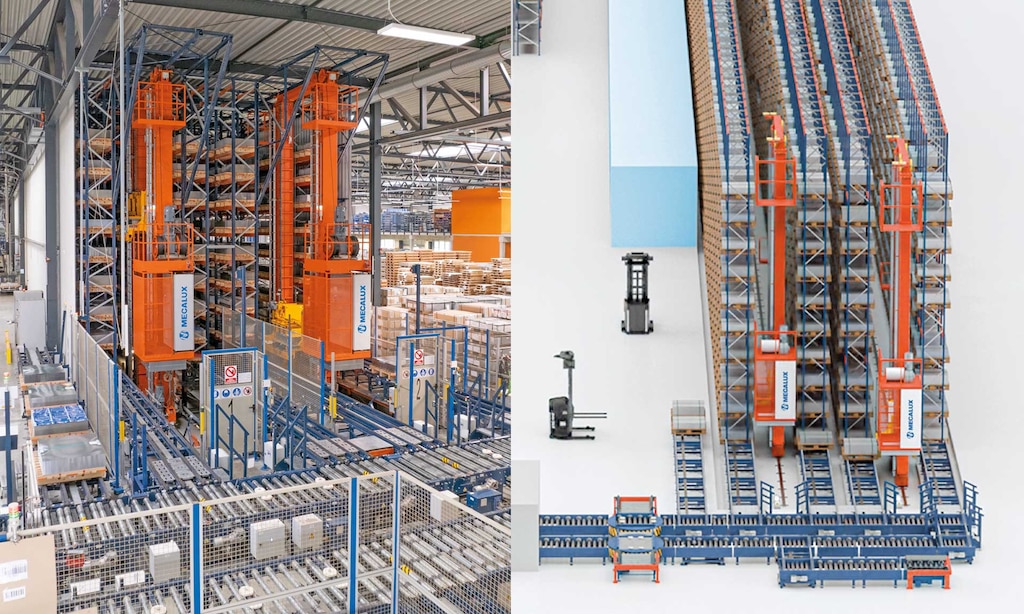

- Production. The storage and handling equipment is manufactured after simulating its mechanical and operational characteristics to guarantee throughput.

- Commissioning. Simulation helps optimize warehouse performance, enabling a faster start-up and preventing issues related to design and flows.

- Future development. Once operational, simulations can be conducted to identify improvement opportunities, such as warehouse expansions or new configurations.

Interlake Mecalux’s simulation software

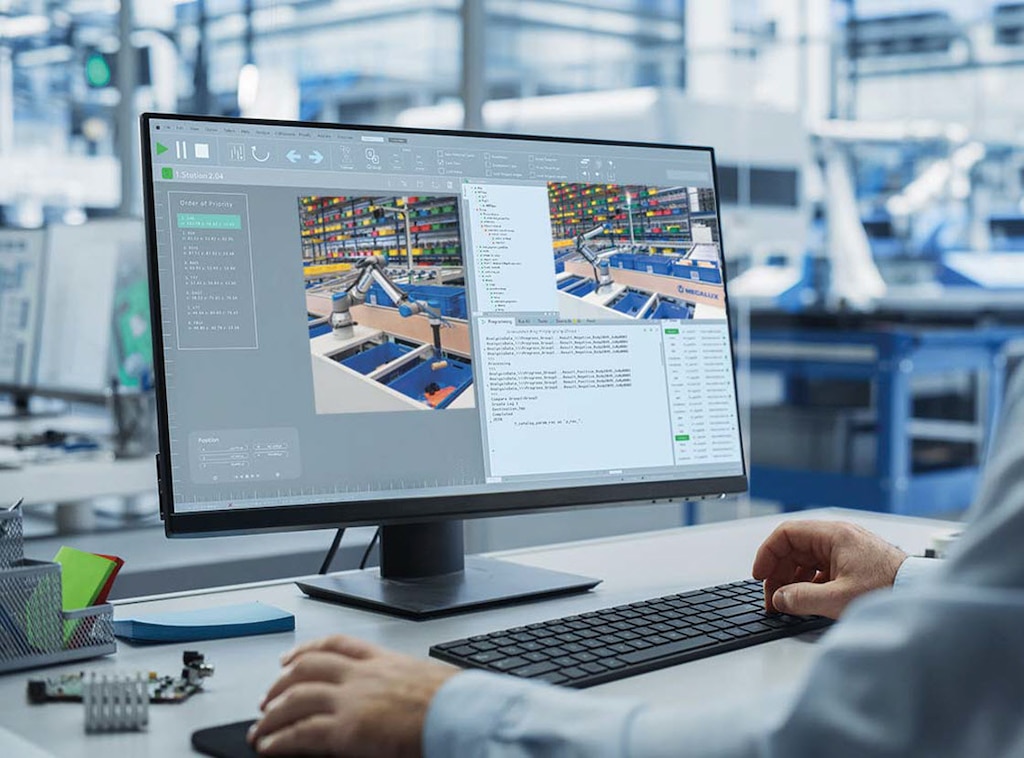

Interlake Mecalux’s technical team uses proprietary simulation software to design, test, and optimize its clients’ warehouses. Real company data are input into the system. These include basic needs as well as solutions to be integrated into the facility, e.g., stacker cranes, mobile robots, or conveyors.

The software sunsequently generates a digital twin. Leveraging the client’s real data, this virtual replica predicts the warehouse’s future performance and anticipates potential bottlenecks. Before implementing the solution, the model runs simulations to calculate operational capacity and determine the most effective way to execute cycle times and material flows.

Interlake Mecalux also refines the design of its products by incorporating empirical data from each machine into the simulation software. This ensures that the solution can adapt to the client’s needs and validates that the warehouse will operate according to specifications.

Advantages of simulation software

|

Optimal designLogistics solutions are designed to meet companies’ operational expectations while minimizing performance-related risks. |

Error preventionAdvanced analytics tools help correct potential design flaws, avoiding additional costs. |

|

Creation of a test environmentThrough simulation software, logistics strategies are validated through a virtual representation. This eliminates the need for real-world tests, which are often costly and sometimes impractical. |

Movement previewClients can view a practical demonstration of how their system will operate before it goes live. |