Artificial intelligence (AI) is the present and future of technology. But how can we implement it to make our production and supply chain processes increasingly more efficient? AI opens up a huge number of scenarios to discover and delve into. It also provides the possibility to explore new business opportunities to achieve greater growth, profitability, and sustainability. An example illustrating this is the use of AI combined with digital twins (digital replicas of a process, product, or service) to personalize production according to a customer’s requirements.

What is artificial intelligence?

AI is the simulation of human intelligence by machines and computer systems. Its aim is to create machines that can act like people. Although that may have seemed like science fiction a few years ago, it is closer and closer to becoming a reality.

The term artificial intelligence was coined by American scientist John McCarthy in 1956. However, British mathematician Alan Turing had previously raised the question of whether machines could come to think like humans with the Turing test. According to this criterion, the intelligence of a machine can be judged on the basis of whether its responses are similar or discernible to those of a human being.

By applying AI to the field of software, software is able to change its behavior without being specifically programmed to do so.

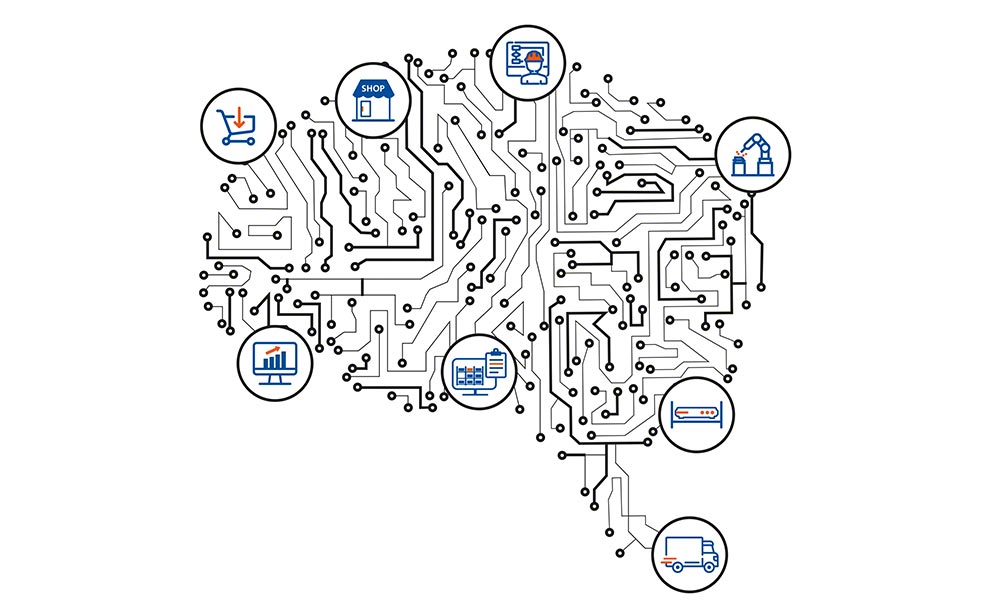

To carry this out, AI has a deep neural network (DNN) that analyzes complex information, such as videos, images, and datasets in order to decide, detect, and predict based on the data received.

In line with the data collected, analysis, and observation, AI systems can detect patterns, make probabilistic predictions, and operate without supervision in certain situations. AI is used in many fields, such as machine vision and automatic speech recognition.

It remains to be seen whether innovation will enable new technologies to sense, comprehend, and act. The latest advances in AI, the Internet of Things (IoT), and machine learning have made it possible for machines to process images, sound, and voice; they analyze the data obtained, make decisions accordingly, and perform actions in the physical world.

Three factors have fostered the development of AI

- Unlimited access to processing capacity. The cloud has been the driving force behind data intelligence given its flexibility, elasticity, and efficiency, in terms of both storage space and the speed and security of data management and control.

- Rise in data intelligence (big data). This is not only a question of storing a vast amount of information, but also of managing and exploiting it.

- Proliferation of specialized hardware to power AI, such as GPU Computing, FPGA, and TPU. These tools are much faster and more advanced when it comes to analyzing data.

One of the premises of AI is to ensure that production processes are increasingly efficient

How is AI implemented?

The application of AI, in both our everyday lives and the professional world, is a growing phenomenon. According to a study by Gartner — a global leader in market research and consulting — centered on around 200 IT and business professionals, 24% of organizations surveyed increased their investments in AI, while 42% kept them unchanged since the start of COVID-19.

“Enterprise investment in AI has continued unabated despite the crisis,” says Frances Karamouzis, Distinguished VP Analyst at Gartner. The report adds that 79% of respondents affirm that their organizations were exploring or testing AI projects, while only 21% said their AI initiatives were in the production stage.

Up to now, most businesses have invested in automation to strengthen their development. Nevertheless, the latest advances in AI underline the fact that companies need to go further and leverage the potential of machine intelligence if they want to differentiate themselves from their competitors.

AI development and implementation phases

- Choose the application areas. First, make a list of the fields in which it would be possible to employ this technology. To do so, it is necessary to identify the expert for each use case and verify the existence of valid data sources and KPIs that provide objective data on progress.

- Prioritize the application areas. Estimate the value that each of the cases identified has for the business, in addition to anticipating the possible difficulties that could arise when implementing AI (such as the lack of adequate data or the impossibility of effecting improvements). Radical changes should not be introduced until improvements to existing processes have been implemented progressively.

- Group the application areas. The application fields should be grouped according to the data that feed them so that they can be worked on together and not in isolation.

- Implementation. Any of the project implementation methodologies using programming languages such as CRISP-DM should be used. If the company lacks experience in implementing this technology, it is preferable to work with a partner with technological expertise in this field.

- Assessment. Determine in the test datasets whether the application of the AI prototype is really enhancing the KPIs to be improved.

- Launch. Once the solution has been successfully evaluated, it must be rolled out in a controlled way to check that the test results match up to reality. In other words, it is necessary to verify that the system correctly adapts to the data received from the real environment.

- Full deployment. This consists of the complete rollout of the system to then move on to the next set of application areas.

AI makes it possible to explore new business opportunities to achieve further growth, profitability, and sustainability

AI applications in logistics

Although AI applications in logistics are still being developed, they are expected to reach their maximum potential within the next few years. In any event, some practices have already gained a foothold in the sector:

- Prediction of consumer trends. Artificial intelligence makes use of big data for logistics purposes: it cross-references internal information, such as sales figures, with data extracted from forums, social media, and other internet sources. Thus, the system can make deductions about users’ consumption intentions to predict demand behavior. This serves to implement anticipatory logistics, which avoids stockouts and the storage of excess merchandise. It is a good way to mitigate the waste of resources.

- Automation of storage operations. One of the best examples of AI in logistics is automated warehouses. They combine two fundamental systems: warehouse automation and warehouse management software. Together, they ensure logistics that integrates both transportation and storage movements as well as operational management. This work-sharing generates patterns over time that are continuously analyzed. This way, AI helps to optimize resources and correct movements in the case of variations in flows.

- Selection of transportation routes and the most efficient movements. AI greatly simplifies the coordination of logistics transportation. On the one hand, the WMS keeps a digital X-ray of the company's facilities and records all intralogistics movements that occur. AI processes these data and organizes the movements, including those of self-driving vehicles that react to their surroundings and adjust their route as required, and those of operators aided by handling equipment. On the other hand, AI also manages the goods transportation fleets, interpreting up-to-date traffic information and incorporating it into the on-site systems. Using this data, the software maps out the most suitable routes for delivering the various orders; it also adjusts itineraries in real time if any incidents occur.

- Stricter control over supply chain data. The automation of supply chain processes — enhanced by AI — opens the door to managing inventory in real time, issuing supply orders instantly, and monitoring orders accurately, among other actions. Likewise, data integration and improved traceability systems mean that businesses can satisfy users’ need to know. For example, the typical “Where’s my order?” question about a package purchased via an e-commerce retailer can be resolved quickly and effectively by implementing AI chatbots.

With AI, companies can take inventory in real time, issue instant supply orders, and accurately monitor orders

How does Mecalux implement AI?

Mecalux Software Solutions works in several fields of application to add value to Easy WMS, the warehouse management system that runs approximately 1,200 facilities around the world. These are some of the areas in which it is working:

Improved picking in e-commerce warehouses

One of the challenges of an e-commerce facility comprises managing the large number of outgoing orders. Therefore, when it comes to picking the SKUs that make up each order, it is extremely important to optimize operator routes.

The application of AI enables the system to give each operator instructions on each particular order. The system can do this through history-based learning. This achieves maximum efficiency, especially in warehouses with intense picking operations such as e-commerce facilities.

Predictive system to optimize order picking

AI applied to Easy WMS can be useful for forecasting the time required to prepare new orders, based on the analysis of historical data. The main objective of the predictive system is to estimate well in advance the time allocated to picking according to the type of orders entering the system and the items that make up each of them.

Additionally, the warehouse execution system (WES), as part of Easy WMS, is capable of deciding when and how picking orders are released to operators, thereby ensuring continuous workflows (order streaming).

Labeling and traceability verification

Together with image recognition systems, AI can help to automatically detect serial numbers in packaging processes. For example, it facilitates the identification of serial numbers relating to the appellation of origin of wine bottles and their associated boxes.

The system identifies which items labeled with the serial numbers for the appellation of origin need to be put on the conveyor belt to be packed in boxes. It also recognizes the serial numbers as they move along the conveyor, which helps to pinpoint the box in which a specific bottle has been placed.

The use of AI in image recognition substantially improves current hardware equipment.

Conversational user interfaces

Mecalux will soon incorporate a mechanism to consult KPI dashboards and results via platforms such as email, Skype, and Telegram.

The advantage of this system is that users can access warehouse productivity data instantly from anywhere in the world with an internet connection, navigating the dashboard in an agile way.

Mecalux promotes AI

To say that AI forms part of our day-to-day and logistics is a truism. So, too, is the idea that technology is an ally for further improving supply chain processes. For those reasons, Mecalux has spent years developing technological innovation projects and applying their results to improve warehouse management. Its end goal is to boost its clients’ efficiency and profitability.