LOGISTICS RESEARCH

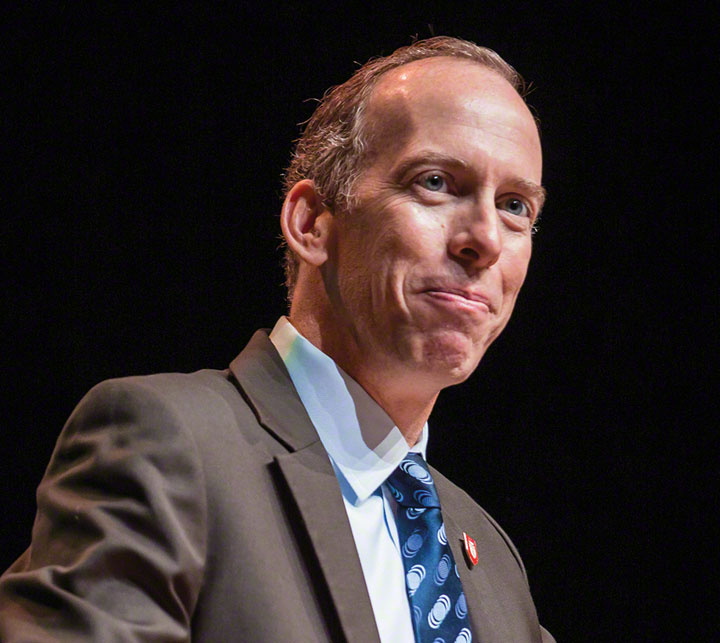

By Thomas J. Goldsby, Donald F. Kuratko, and Michael G. Goldsby

Entrepreneurship is commonly viewed as the combining of existing resources in creative ways to exploit an opportunity. Supply chain management (SCM), meanwhile, is described as the process of planning, implementing, and controlling operations to satisfy customers as optimally as possible. Both have risen to prominence over the last three decades and, arguably, represent the most vital means to instill growth and create market value.

So, why have these two fields not been integrated more meaningfully? One explanation is their seemingly divergent perspectives directed toward risk. Entrepreneurs are believed to have a much higher tolerance for risk and, even, a propensity for risk-taking. Supply chain professionals, on the other hand, are renowned for their risk aversion. Yet, as the COVID-19 pandemic demonstrated, supply chain leaders and organizations that embraced risk in the form of enhanced agility were rewarded.

Can supply chain professionals learn from entrepreneurs?

In light of the current business environment — characterized as highly volatile, uncertain, complex, and ambiguous (i.e., VUCA) — companies would be wise to encourage supply chain professionals to develop an entrepreneurial mindset. The goal is to explore untapped avenues for entrepreneurial activity that yields alternatives in supply chain design, inputs, processes, relationships, and outcomes. In support of this premise, we offer the corporate entrepreneurship assessment instrument (CEAI), a diagnostic tool developed by Kuratko et al. over the years. We have adapted the CEAI scale for supply chain management (CEAI-SCM) to enable supply chain professionals to instill an entrepreneurial mindset in their businesses.

Innovation in the supply chain

Corporate entrepreneurship (CE) — as the process of creating strategies for pursuing new opportunities for growth and renewal inside existing organizations — resembles the innovation, risk-taking, and planning of nascent startup efforts. However, size, legacy, mission, and brand discipline place obstacles toward major innovation for larger firms that emerging enterprises do not encounter in the early stages of entrepreneurial endeavors. CE, therefore, is better enhanced when a company’s executive team recognizes, supports, and encourages middle managers to explore and develop new business opportunities.

Nevertheless, SCM rarely encourages visionary thinking, and the maverick path is often unwelcome. Rather, supply chain professionals resort to metrics that emphasize customer service achievement, operational efficiency, cost reduction, asset utilization, and more recently, sustainability. Certainly, these are critical dimensions of performance, but they fail to account for the contribution to top-line (revenue) growth and the customer attainment/retention potential of the supply chain, particularly in new markets.

Yet, supply chains are often under-considered bastions for innovation. For one, they account for the largest share of employees in many organizations. This represents an immense collection of minds that understand the company’s product/service portfolio, market prospects, what sells and does not, capabilities and limitations found in the supply base, and how products are made and moved. The cross-functional, boundary-spanning nature of these employees’ work contributes to what is known as supply chain orientation, a concept that holds game-changing potential for entrepreneurs in corporate and startup situations.

Real-world business success stories

History evidences the success of leaders and organizations that recognize and support the supply chain’s vital role in innovation processes. One example is the iPhone and Gorilla Glass. When Steve Jobs reimagined the smartphone industry by creating a phone that was more interactive and had more space for visuals, bringing a durable touchscreen to the new device was a significant supply chain challenge.

Jobs realized that a critical resource for the iPhone was Corning’s Gorilla Glass, which was strong enough to withstand phone-drop impact and yet conducive to the finger interaction needed on a screen. The problem was that Corning did not have the capacity to meet Apple’s needs and had no interest in doing so. Jobs flew to New York to meet with Corning CEO Wendell Weeks to look him in the eye and say: “Yes, you can do it. Get your mind around it. You can do it.” When Weeks retold this story, he explained that Corning managed to produce a glass that had never been made in just six months. Apple continues to profit from the product and supply chain breakthroughs that Jobs and his successor, Tim Cook, put in place over a decade ago.

Coca-Cola has a similar story. In the early 2000s, carbonated beverages were the target of scrutiny by consumers, the media, and regulators. The business was in need of an innovation. The story goes that a senior leader at Coca-Cola saw a Cargill advertisement with the closing tagline: “Collaborate, create, succeed … this is how Cargill works with customers.” Cargill had just discovered rebiana, an extract from the stevia plant. It was all-natural, very sweet, and calorie-free. However, it had a bitter after-taste that the business had not yet resolved. After initial discussions, the two giant companies set out to address the bitter flavor, sending food scientists from each to the labs of the other. Ultimately, the problem was fixed, and Coca-Cola and Cargill entered into an exclusive agreement on the use of the latter’s rebiana output.

The role of agile supply chains

Gligor defined supply chain agility as a company’s ability to quickly adjust tactics and operations. Prior to the pandemic, organizations regarded this quality as something of a luxury. Developing responsiveness involves agility, resilience, flexibility, adaptability, and improvisation. And at the heart of the multidimensional construct of responsiveness is change — a concept that does not come easily to most supply chain professionals due to the risk it entails. McKinsey notes that mid-level managers in other industries are also risk-averse. These professionals are particularly rife for opportunities that can improve the business without risking its livelihood or causing massive financial distress.

Supply chains play a substantial role in the success or failure of new products, services, and processes. But executives are directing more attention to the creation of new products and services, with sourcing and distribution as an afterthought of CE. Research in CE demonstrates that entrepreneurial behaviors are individually driven but very much dependent on the environment of the corporation to be conducive to CE activity. Fulop asserted that middle managers were critical to the successful implementation of CE. Cross-functional interaction with other department middle managers that goes beyond these supply chain confines would be key for supply chain innovators. After all, history is replete with examples of middle managers and employees who started their own companies because executives would not consider their ideas.

Result of the CEAI scale

Our application of the CEAI instrument for supply chain management (CEAI-SCM) consists of 48 Likert-type items. It revealed that there are five antecedents of middle-level managers’ entrepreneurial behavior.

Five antecedents of entrepreneurial activity

- Management support. Willingness of top-level managers to promote entrepreneurial behavior and facilitate necessary resources.

- Worker autonomy. Top-level managers’ commitment to delegating authority and responsibility and tolerating failure.

- Rewards/reinforcement. Recognition of performance and significant achievements.

- Time availability. Assurance that workloads allow time to pursue creation.

- Organizational boundaries. Precise explanations of outcomes expected; mechanisms developed for evaluating, selecting, and using innovations.

How to develop an entrepreneurial mindset

Certain research avenues look to advance both entrepreneurship and SCM simultaneously. This involves identifying new ways to do new things in the scope of operations that are essential for products to reach end customers. Technologies that hold this potential include digital platforming, artificial intelligence, and 3D printing (i.e., additive manufacturing). We should also point out that non-technological advents warrant consideration. These include innovations in management methods and practices (e.g., collaboration, digitalization, and operational excellence).

In conclusion, the importance of instilling an entrepreneurial mindset into all organizations cannot be overemphasized. When there is an opportunity to reach more customers in a novel way, SCM supports — and often initiates — the recognition of such market opportunities.

Original publication:

Goldsby, Thomas J., Kuratko, Donald F., Goldsby, Michael G. 2024 “Developing an entrepreneurial mindset in supply chain managers: Exposing a powerful potential.” Journal of Business Logistics, volume 45, issue 2 (Wiley).