Clad rack warehouse: maximum capacity

Interested in maximizing both your storage capacity and operational speed? A clad rack warehouse could be the perfect choice for enhancing your intralogistics processes.

What is a clad rack warehouse?

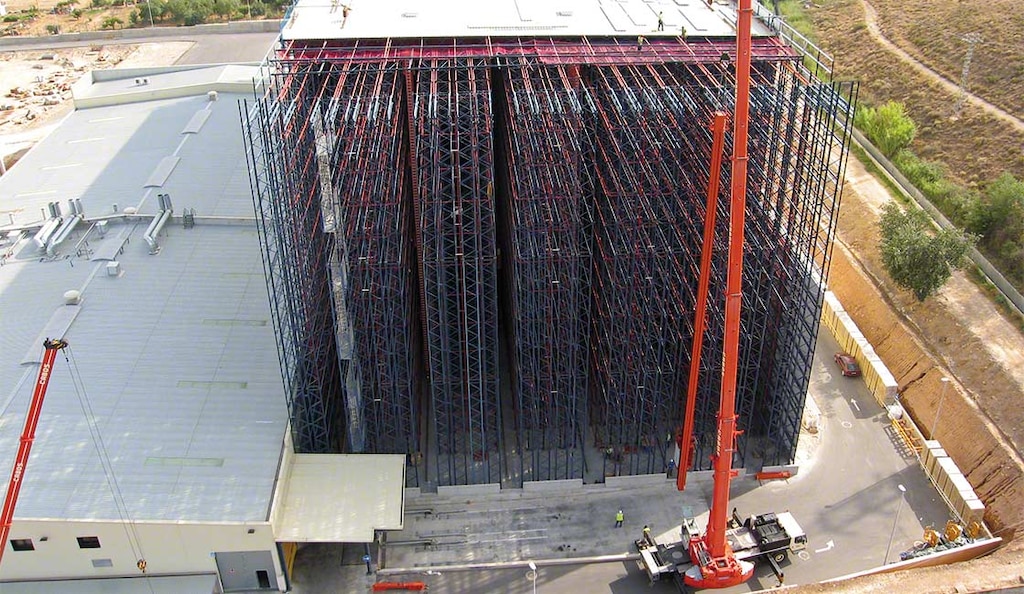

A clad rack warehouse is a facility where the racks that hold the goods are part of the frame that supports the building. The racks are the main structural component of these facilities, which require neither pillars nor columns.

Clad rack warehouses support the loads of stored goods in addition to the side and roof enclosures and the effects of external agents (e.g., wind force). This solution brings companies multiple advantages, including space maximization. However, it must be designed to spec by qualified professionals.

Advantages of clad rack warehouses

Also known as rack supported buildings, clad rack warehouses offer businesses several benefits:

- Space maximization. By housing goods from floor to ceiling, these high-density facilities significantly increase the total storage capacity.

- Fast construction. Clad rack warehouses require minimal civil engineering work. This facilitates their construction, which begins by pouring a concrete slab on a compacted surface.

- Great height. Maximum building height restrictions are defined by local regulations, though it’s also crucial to consider the material handling equipment your company will use. Generally, these facilities are under 150' tall. That said, one way to maximize efficiency is to use stacker cranes or mini-load systems. These automated storage and retrieval systems (AS/RS) reach considerable heights without jeopardizing safety.

- Easy expansion. These structures, composed of assembled elements, can be extended very simply. Congelados de Navarra, a producer of deep-frozen vegetables, built a 118' tall clad rack warehouse for 27,000 pallets in partnership with the Mecalux Group. A major increase in sales led it to set up a second cold store with a capacity of 36,000 pallets attached to the first. Years later, it created another space with the same characteristics for semi-finished products.

- Safety. These buildings resist inclement weather such as wind and snow.

How does a clad rack warehouse work?

Clad rack warehouses can be tailored to individual customer needs, but by and large, they fall into three major categories:

- Automated clad rack warehouses. Incorporating AS/RSs such as stacker cranes for pallets in a clad rack warehouse leverages up to 150' of vertical space to store goods. Moreover, these automated facilities are typically operated using a warehouse management system like Interlake Mecalux’s Easy WMS. This makes them one of the most efficient intralogistics options.

- Clad rack warehouses for cold storage. These designs are compatible with cold stores for refrigerated or frozen products. They can be manual or automated.

- Manual clad rack warehouses. Operations in these types of rack supported structures are performed using forklifts.

How is a clad rack warehouse built?

The design and assembly of clad rack warehouses differ from those of conventional buildings. They normally involve these steps:

- Calculations. The building is designed considering the weight to support and other aspects such as standards.

- Foundation construction. The concrete slab is laid. It will support the structure and drainage systems.

- Racking installation. The racks are assembled, starting from the front end.

- Cladding. The enclosures (roof and facades) are attached as the work on the rack installation progresses, with the racks serving as the building’s structural components.

- Introduction of machinery. If the clad rack warehouse is automated, handling equipment (e.g., stacker cranes) is incorporated at this stage.

- Other areas. Receiving and shipping zones are set up in building annexes.

- Final. The remaining racks and cladding are assembled.

Companies with clad rack warehouses

More and more organizations from different industries are integrating clad rack warehouses into their logistics activities. They’re advantageous for companies in any sector, including automotive, food, pharmaceutical, transportation, and logistics providers. In addition to Congelados de Navarra, these are some companies that use them:

- BASF. Chemical manufacturer and distributor BASF has a large clad rack warehouse in the Brazilian town of Guaratinguetá. At 98' high and 331' long, it provides 15,070 ft² of floor space for storing chemicals.

- Cepsa. “We’ve integrated our manufacturing, packaging, and shipping processes into a single facility,” say Cepsa representatives. This energy group specializing in hydrocarbons reduced its logistics costs by building a clad rack warehouse in the Spanish town of San Roque.

- Würth. German company Würth markets all varieties of professional fasteners, joints, and assembly components. At its clad rack warehouse in Agoncillo, Spain, it handles tens of thousands of SKUs. Würth now stores 15,000 pallets in just 37,674 ft², which would have been impossible in its former conventional facility.

Interlake Mecalux clad rack warehouses

Are you looking to open a storage facility that maximizes space utilization, is easily expandable, and has annexes for production and shipping? If so, a clad rack warehouse could be the solution. At Interlake Mecalux, we have extensive experience in designing and assembling these types of logistics centers. We’ll guide you in planning and building the warehouse your business needs. Contact us, and we’ll help you transform your processes.