Supply chain pressures and how to mitigate them

In situations of uncertainty, supply chain pressures can make companies’ logistics operations more complex. Consequently, businesses have to adapt their processes to respond to these market changes. Tools are available to gauge supply chain pressures, such as the Global Supply Chain Pressure Index (GSCPI) designed by the Federal Reserve Bank of New York (New York Fed).

Supply chain pressures are linked to disruptions that affect material prices, manufacturing costs, and demand levels. Against such a backdrop, organizations need to figure out how to guarantee supplies of products without incurring logistics costs that could undermine their performance. This is reflected in the article Global supply chains in a post-pandemic world, published in Harvard Business Review: “The challenge for companies will be to make their supply chains more resilient without weakening their competitiveness.”

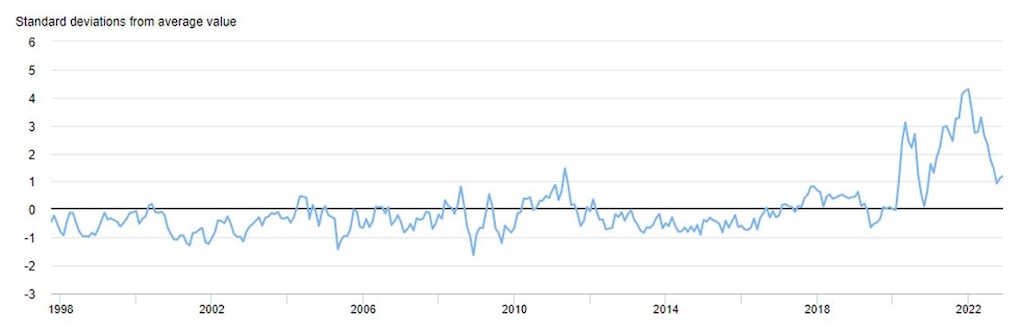

Analyzing worldwide supply chain pressures provides insight into the current state of international trade and logistics. A report from consulting firm Oxford Economics shows that although supply chain pressures are easing, new challenges lie ahead in 2023: “Inventory levels relative to underlying demand are generally improving since this same time last year … and are a good sign in the context of managing supply chain pressures. However, if they rise further amid a continuing demand slowdown, this could lead to a negative whiplash effect.” Supply chain pressures have increased since the start of the coronavirus pandemic, as indicated by the GSCPI.

Global Supply Chain Pressure Index

As mentioned above, the New York Fed created the GSCPI, which objectively measures the conditions of the supply chain worldwide. This tool combines several international variables relating to transportation and manufacturing, e.g., delivery times, raw material shipping costs, inventory volume percentages, and global customs costs. The barometer is based on metrics that aim to capture the factors that exert pressure on the supply chain, both nationally and internationally.

The purpose of the GSCPI is to help businesses, lawmakers, and consumers understand the state of the supply chain worldwide. “Our goal in constructing the Global Supply Chain Pressure Index (GSCPI) was to develop a parsimonious measure of global supply chain pressures that could be used to gauge the importance of supply constraints with respect to economic outcomes,” say the authors of Global Supply Chain Pressure Index (GSCPI).

The GSCPI works like this: a high value represents more supply chain pressure than usual, while a low value means there’s less pressure.

Economists from the New York Fed designed the GSCPI using data obtained from several sources: the Harpex Index, which measures worldwide container shipping prices; the Baltic Dry Index, which tracks raw material transportation costs around the world; and the US Bureau of Labor Statistics, which calculates the air freight costs for product imports and exports. This barometer also employs information gathered from the private sector. The GSCPI analyzes data such as the size of order backlogs and purchased stocks in companies operating in seven markets: the US, the UK, the Eurozone, China, South Korea, Japan, and Taiwan.

How to minimize supply chain pressures

Resilience is emerging as a key attribute for supply chains, especially in times of high pressure. An analysis by economists from the International Monetary Fund (IMF) indicates that “supply chain disruptions in the wake of the pandemic have brought to light the importance of resilience — that is, the ability of supply chains to continue to operate even when hit by shocks.”

So, how can businesses limit disruptions through resilience? “To prepare for disruption, you have to map your supply chain to know who the organizations upstream are. You have to prepare ahead of time and know what you’ll do if you can’t deliver everything to your customers and have to prioritize some customers over others,” says Yossi Sheffi, Director of the MIT Center for Transportation and Logistics. “You also need to centralize all the information and the decision-making process to make sure decisions account for all the system-wide effects.”

Technology stands out as an effective solution for managing supply chain pressures. In a context in which businesses need to shorten delivery times and bring down logistics costs, process digitization can help to improve responsiveness in the face of disruption. Investing in logistics software provides greater visibility of supply chain operations. The use of applications such as a warehouse management system (WMS) fosters flexible and resilient logistics capable of adapting to changes in product demand.

A study from the Berlin School of Economics concludes that new technologies are an effective way to cushion supply chain pressures: “The impact of digitalization on resilient operations and the [supply chain] can be quite complex. Consider some interplays. Risk in the [supply chain] can be mitigated by the descriptive and predictive use of big data analytics in gaining visibility and forecast accuracy, reduction in information disruption risks, and improved contingency plan activation. Reductions in supply and time risks can be achieved by using advanced trace & tracking systems, leading to real-time coordinated activation of contingency policies.”

Tools to cope with supply chain pressures

When faced with supply chain pressures, companies are opting for solutions that make their logistics operations flexible and resilient. Implementing digital management applications facilitates visibility of everything happening in your supply chain. And this results in more efficient logistics planning.

A program such as Interlake Mecalux’s Easy WMS minimizes the risk of error in raw material procurement, stock control, and order processing and dispatch. The software provides logistics managers with up-to-date, real-time information on warehouse performance.

Interested in digitizing your operations to optimize your supply chain? Don’t hesitate to contact us. One of our expert consultants will advise you on the best solution for your company.