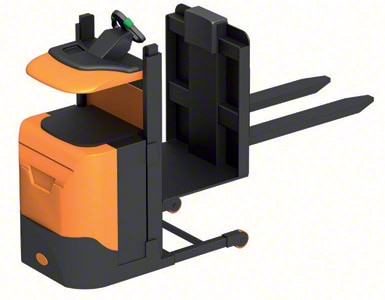

Order pickers are a further development of forklifts and electric stackers. They are specially designed to help with the preparation of orders, allowing the operator to access the machine’s controls from one side and the pallet or load from the other, speeding up the goods collection process from storage racks.

Some pickers work at ground level and others can rise. Both types have three basic characteristics.

First, the pallet truck must be capable of housing the operator, so the body of the machine is separated from the load forks. A small platform on which the driver can stand opens up in this space.

Second, the operator must access the controls from this position, so the configuration of the shaft has been changed, turning it 180º with respect to how this element is assembled on standard pallet trucks and stackers.

Finally, for the most common use for these machines, it is helpful, but not essential, to use the versions with extra-long forks (63 to 94.5 inches), since this allows two or three orders to be prepared at the same time.

There is a wide variety of machines available on the market with very different characteristics. However, they can be grouped into three main types.

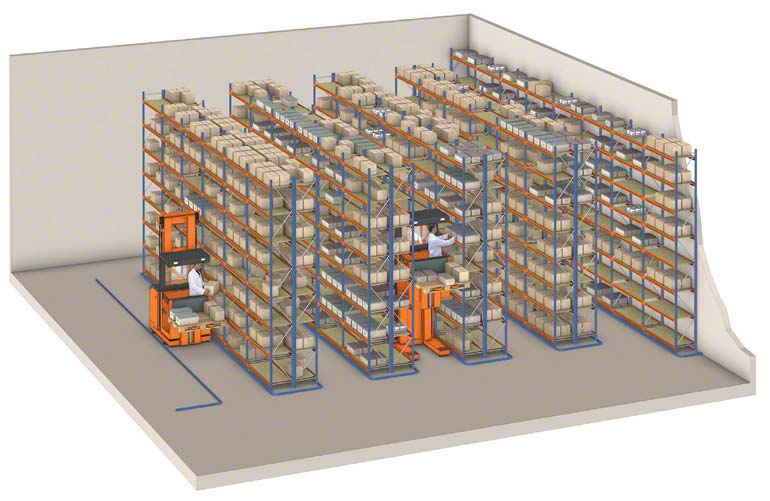

Order pickers operating in a pallet rack installation.

| Ground level pickers |

|

The most basic type of picker is the one which works with loads at ground level. Although these can only pick items on the first level (racking unit, on the ground, etc.), some models have a small platform on which the operator can stand to access higher spaces. The machine has space for a driver and can transport one or two pallets. Pickers with extra-long forks can manage two or three pallets at the same time. |

| Low level pickers |

|

The second type of picker is the one which works at a low level. Given the need for operators to be able to access higher levels, these machines have been developed using those working at ground level as their starting point. |

|

There are two options for this type of machine. The simpler option has a non-slip platform at the top of its structure. Since this is usually fairly high up, a small intermediate ladder must be installed between the operator’s platform and the upper platform. This ladder can be either fixed or foldable. |

| Another, more expensive option consists of adding an electrohydraulic lifting system to the platform where the operator is, so that the operator can be raised as required. |

| Mid- and high-level pickers |

|

This type of picker can reach medium and high levels. Mid- and high-level pickers consist of a body with a traction motor, a hydraulic pump, a battery, and control devices. This body is connected at its base to two support legs mounted on small wheels. A lifting mast is also attached to the body, and the cabin in which the operator stands moves up and down this mast. |

|

Two forks can be welded to the cabin; in this case, the lifting height is limited to what can be reached by the floor height of the operator’s cabin. Another option is for the forks to be mounted on a trolley on a second lifting mast incorporated into the cabin, so that the operator can raise and lower the load to the most convenient working height. |

The aisle width required to operate these machines can be ±45.3 inches when pallets face forward, and ±59 inches when pallets face sideways. The maximum lifting height that can be reached by the highest pickers is 32.8 feet or 36.1 feet.

One alternative to this type of machine is the combi type VNA truck, which has a maximum lifting height of over 39.4 feet.