Warehouse layout design

The layout of a warehouse must establish the following areas: loading and unloading, reception, storage, order preparation, dispatch and services.

Warehouse design must include the organization and distribution of space into different operational zones and storage rack areas. Generally, a central warehouse must consist of six sections: reception, quality control, adaptation of unit loads, storage, order preparation and dispatches. Usually, these six sections or departments can be grouped together into three areas: reception, storage and dispatches. These are explained below.

This area covers the receipt of goods, quality control and, where required due to the nature of the product or goods, the adaptation of unit loads.

The reception area must be adjacent to the unloading docks, and of an appropriate size to manage all goods that could arrive in the warehouse during a normal working day. If possible, there should be an additional area large enough to deal with any possible unscheduled increases in goods received.

If it is necessary to adapt received unit loads, the surface area must be increased and the resources required to carry out this task must be made available. This includes having the necessary personnel, suitable working benches and tools, reserving part of the storage space for empty packages and having a system to remove the original packaging.

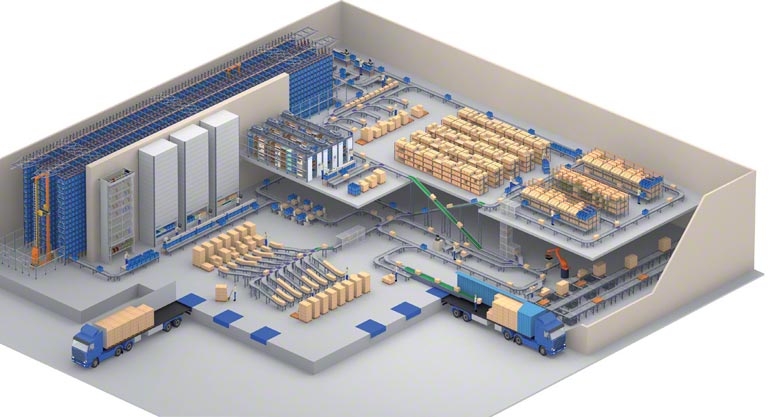

Warehouse designed for an express transport and distribution business

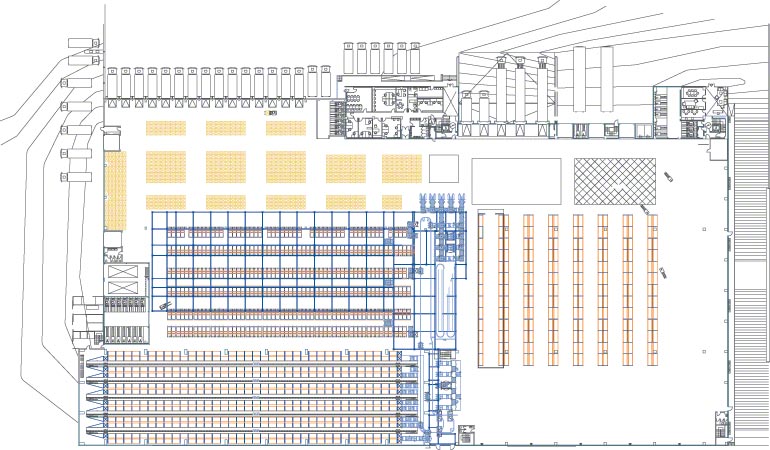

Central warehouse for food product distribution

The design of the storage area will depend on whether or not orders will be prepared in the installation and whether this preparation will take place at the racking bays.

In a central warehouse, this area can be made up of one or more sections. Since the objective of this article is to provide the reader with as much information as possible about the different options, here it considers, for example, an installation that receives various types of products, in different quantities, with a number of different rotation ratios and with complicated storage requirements.

To design a warehouse with these characteristics, the first step is to study the products’ rotation ratios, sorting them into three categories: low-, medium-, and high-rotation. The determination of these three categories is, of course, very subjective. Nonetheless, it can and must be determined by creating an average ratio as the point of reference. Products with a ratio close to this will be classified as medium-rotation. Those with much lower figures will be classified as low-rotation, while those with much higher figures will be classified as high-rotation.

Once the products, their volumes, and their corresponding rotations have been established, the next step is to position them inside the warehouse. In doing so, three factors must be taken into account:

Thus, a central warehouse with these characteristics could include:

- Block storage or a compact storage area, used for high-rotation products where volume is more important than accessibility or picking speeds. Based on the quantity of the product and capacity available, it is possible to use a configuration in blocks or any of the compact storage systems.

- An area with racking units which, based on the quantity of high-rotation products that exist, can be just storage (where the load is only positioned) or mixed, with picking racking units built in.

If it is purely storage, there are a number of options in terms of handling equipment to use, including conventional forklifts (which need 11.5' to 13' wide aisles), reach trucks (aisles must be 8' to 10' wide), VNA trucks (aisles 5.6' to 7.2' wide) and stacker cranes (aisles of less than 5.6'). The choice of handling equipment is not determined simply on the basis of the space required between racking units, but also, fundamentally, on the relationship between the storage volume required and that available. It is also essential to take into account the different lifting height limits of each type of machine (see "Forklift equipment").

Sketch of the different sections in a central warehouse

Another very important factor is the investment required if adopting one system or another. The more sophisticated the handling equipment used, the greater the cost. Similarly, one must not forget the return on investment, since the most sophisticated systems, with a largest initial cost, can be the fastest to generate a positive return on investment (ROI).

On the other hand, if the number of products with a high rotation is very significant, a mixed storage area can be useful. Given that the fastest picking is normally carried out at the lowest possible height, while the most profitable storage is at the greatest possible height, it is useful to design a configuration of racking units with the preparation of small pieces at medium height (and storage in the rest), or to install automated systems.

This area contains both the order preparation department (with orders prepared on the ground or from racking units) and the dispatch department.

This is the area that must be used for the preparation and, where necessary, the packaging of orders received from the rest of the warehouses in the chain. To this end, it must have the right resources and no expense must be spared on these resources under any circumstances, since this is the part of the warehouse that has the greatest bearing on the company’s public image and reputation. If the preliminary preparation of orders is carried out on the racks, this simplifies the work of this area significantly.

In any event, order preparation personnel must report to the dispatch department, since it will be responsible for regulating their activities in response to external demand.

Order consolidation in the dispatch area

In terms of operation, if the warehouse has a management system and this has been programmed correctly, the task of preparing orders is limited to placing the products in batches in an area set aside for that purpose.

Orders classified by customer or route

This space reserved for the load must be sufficient to store all items being dispatched on a normal work day. However, it is both useful and necessary to plan an expansion area that can absorb unscheduled peaks in demand. This outbound dispatch area must be as close as possible to the loading docks.

When orders are prepared in a separate area (particularly for picking or individual boxes), an appropriate consolidation area is required. Sorting conveyors that distribute the picked units by order or route can be added nearby.

Buffer zone with completed orders in dispatch area with automatic sorting

Other alternatives to conveyors for taking consolidated loads to the dispatch area are pallet trucks, forklifts, and auto-guided vehicles (AGV and LGV). The above image shows an example of the use of laser-guided vehicles. These LGVs leave the pallets on five tables with rollers, from where they are collected by a shuttle which, in turn, deposits the loads in one of the various disbursement lines fitted with accumulating conveyors.

The layout of a warehouse must establish the following areas: loading and unloading, reception, storage, order preparation, dispatch and services.

A warehouse regulates the incoming and outgoing flows of materials. How complex it may be depends on each business, if product turnovers are high, medium or low, etc.

When paving the floor of a warehouse the loads it must withstand, its composition, joints, and the substrate it will be supported by, etc. must be kept in mind.

A high degree of floor planimetry is crucial in warehouses to prevent handling equipment from breakdown and damage to the rack bays.

Properly designed warehouse access points decreases the risk of interference between vehicles in operation and personnel on foot.

Applying the "just-in-time" concept and using large sized trucks affect the design of warehouse cladding.

Multiple factors determine the number and distribution of loading docks in each warehouse installation, which are either technical, esthetic or organizational in nature.

The technical features of forklift equipment must be kept in mind (height, width, etc.), to properly design an installation.

Racks must fulfill certain clearances to avoid blows from machinery and to place the load correctly in the locations.

What are the most used cladding and roofing for rack-supported warehouses?

Facts like the available space, the customer's needs and resources, among others, are the main data that are collected when planning out a warehouse.