Volumetric weight and its effects on storage and shipping

Due to the importance of volumetric weight in logistics, companies must take into account the size and volume of the goods they move.

What is volumetric weight and what is its purpose?

Volumetric weight is a widely used measurement in the transportation and logistics sector. It determines how much space goods occupy and thus how to store or transport them. Courier companies calculate this to obtain a realistic estimate of the cost of sending a particular order and set the price for this service.

Also called dimensional weight, volumetric weight considers the size and volume of the load and reflects the space required for these products on a rack, truck, ship, plane, or any other vehicle. This indicator is essential for optimizing supply chain efficiency.

Where is volumetric weight used?

Volumetric weight plays a fundamental role in warehouse layout planning, as it makes it possible to design strategies and facilities that multiply the available space. Sectors such as air, sea, and land transportation also employ this measure, while techniques such as palletization and freight consolidation help reduce it.

How does volumetric weight affect shipments?

There is a direct relationship between volumetric weight and the cost of shipping or storing goods: this calculation determines the means of transportation or warehouse resources to be employed. Knowing the allows optimal use of the available cubic feet and avoids deploying vehicles with a greater tonnage than necessary. Here are some of the benefits of calculating it:

- Avoid loading limitations. Volumetric weight is crucial when filling vehicles, but even more so when filling ships or planes. If the load takes up more space than expected compared to its actual weight, this can cause difficulties during the trip.

- Optimize the space. Choosing the most suitable transportation to deliver the goods in question avoids wasted trips or half-full loads. This reduces costs and improves operations, including storage and packaging. Knowing the volumetric weight of the products an organization typically works with can help warehouse experts plan these facilities in the most suitable way. It also makes it possible to utilize lighter wrapping without compromising the safety and security of the items and to facilitate unloading and freight deconsolidation.

- Specify rates. Logistics companies use volumetric weight to set their prices. In this way, they estimate the actual occupancy that the package will have in relation to the vehicle before it’s added to the delivery note.

Volumetric weight calculation and formula

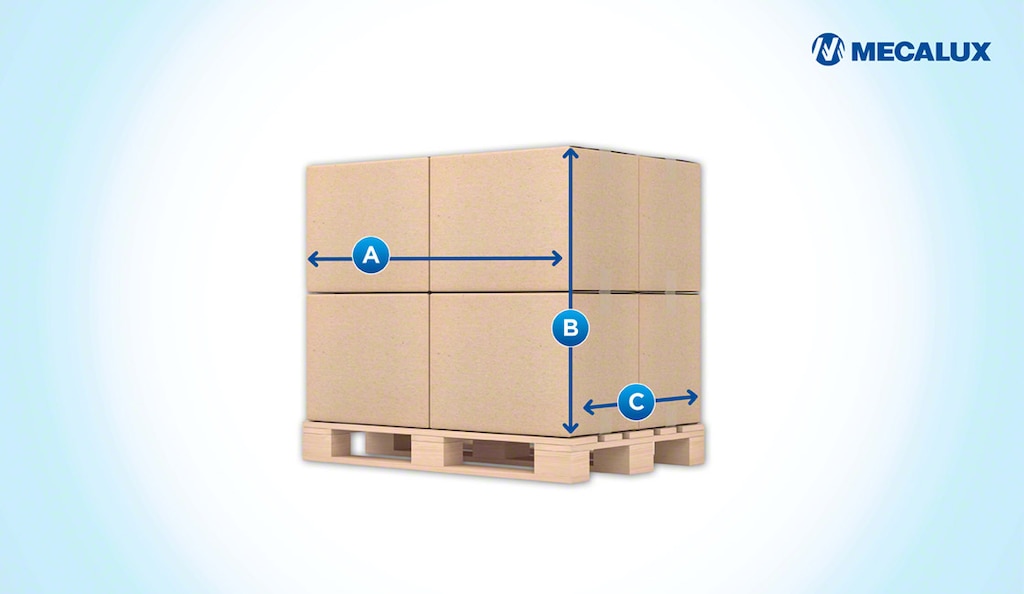

The formula to determine the volumetric weight of an object is very simple. The volume factor that applies may vary depending on the units of measurement used, mileage, and the characteristics and regulations of some sectors. It’s generally used to convert units of measurement to a standard that is expressed in cubic meters per unit of weight (kg/m³ or lb/ft³).

| Volumetric weight = (Length x Width x Height) / Volume factor |

All dimensions in the formula for volumetric weight must be in the same unit of measurement. Once the calculation has been obtained, it should be compared with the actual weight. The higher value is normally the billable weight used to determine the shipping price.

Stackable and non-stackable goods

Another aspect that courier companies take into account when calculating volumetric weight is stackability. Stackable materials are those that can have another load added on top of them during a transportation or storage process. They’re usually uniform, flat, and resistant objects protected by packaging. When the goods cannot be stacked — for example, when they’re over 4' high — the height is no longer relevant for calculating the volumetric weight.

What are the differences between actual weight and volumetric weight?

Actual weight and volumetric weight are related, and the greater of the two is the figure that freight transportation companies consider when calculating their rates.

- Actual weight. This refers to the number of pounds an object weighs. This data is obtained using a scale or measuring equipment and is based on its mass. The actual weight may exceed the volumetric weight if the item is small but heavy.

- Volumetric weight. Measured in volume per unit weight— kg/m³ or lb/ft³ — this determines the space that a load occupies. The volumetric weight of large but light packages may exceed the actual weight.

Although they weigh the same, a pound of straw doesn’t take up the same amount of space as a pound of lead. Some ways to reduce volumetric weight are by using vacuum packaging and avoiding excessively large boxes by opting for more compact formats.

Maximize your warehouse space with Interlake Mecalux

If you’re looking to optimize your logistics facility, at Interlake Mecalux, we’re here to help. As experts in warehouse automation, we developed Easy WMS, a warehouse management system that boosts operations and maximizes the space allocated to stock. Additionally, our Easy DOM, an advanced order management software solution, streamlines processes for companies with multiple distribution centers and omnichannel strategies. Contact us for advice on this and other storage solutions.