Zone picking: sectioning off the warehouse for efficient order prep

How do you improve picking operations to cut down on unnecessary operator travel and boost productivity? One way to achieve this is through zone picking, an order prep method in which the warehouse is broken up into different areas, with one or more operators assigned to each section. The aim of this strategy is to reduce the distances operators travel in the warehouse to enhance efficiency in order picking.

In this post, we delve into zone picking, its main pros and cons, which types of warehouses or logistics centers can benefit from it, and, most importantly, how to implement it.

What’s zone picking?

Zone picking consists of dividing the storage area into different sections based on multiple criteria such as product type, demand level, warehousing conditions, and SKU volume. Each zone is assigned a certain number of operators tasked with picking any product found in that area, which optimizes the time spent preparing orders.

Zone picking is generally implemented in companies with a high number of varied orders, such as e-commerce retailers, where each order can be made up of items of various sizes, uses, or sections. Assigning the products to specific sections prevents unnecessary movements of both operators and goods in the facility.

Types of zone picking: sequential or simultaneous?

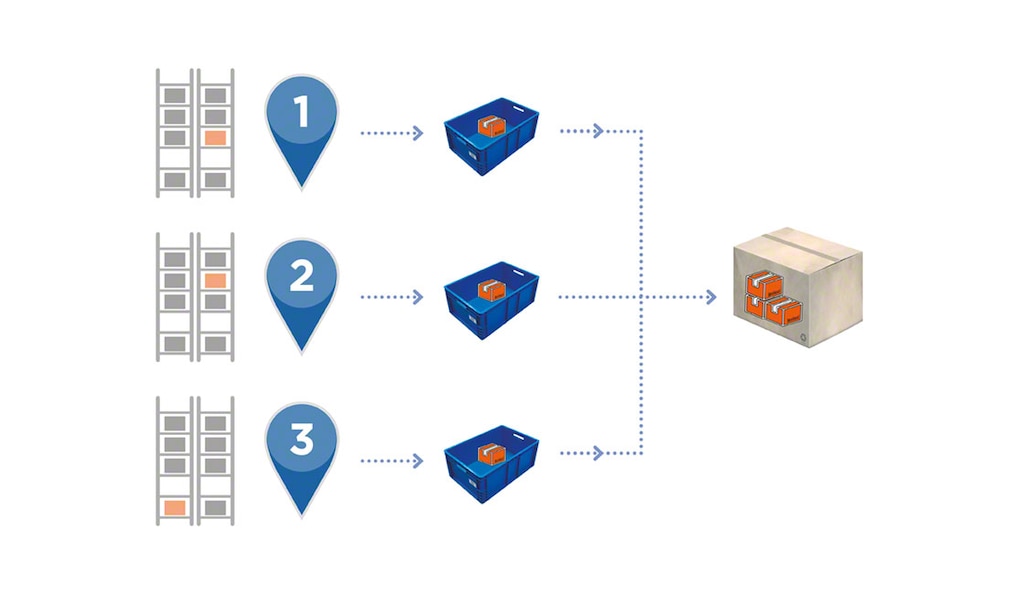

In zone picking, the warehouse is divided into areas, each of which is reserved for a specific number of operators. When an order requires products from various sections, this picking method can be sequential or simultaneous, depending on the number of orders to be prepared at the same time.

Sequential zone picking (pick and pass): this technique involves a single container per order, which moves through the various areas (by means of a conveyor, for instance). The operators in charge of each storage area deposit the items indicated on the delivery note or RF scanner into the container. When the container reaches the end of its journey, the order is already consolidated.

Simultaneous zone picking (pick and merge): in this case, the operators in each section work on the same order simultaneously, each with their own container. This way, the operator in one zone doesn't have to wait for the employee in the previous section to finish to be able to work on the order. Once all the operators have finished their tasks, the order is consolidated in another space (the products from the different areas are grouped together into the corresponding orders). As there is no interference between employees, this strategy saves time and streamlines the final packaging process.

Benefits (and drawbacks) of zone picking

Zone picking ensures:

- Efficient routes. It minimizes operator movements in the facility, enabling workers to prepare the maximum number of orders in the shortest time possible.

- Error reduction and speed. The warehouse management system (WMS) tells the operators the exact product quantities to place in each container, expediting their tasks and limiting errors that could be made.

- Elimination of gridlock. Zone picking facilitates better organization of the facility. Less operator travel in the building prevents traffic jams as well as accidents.

- Productive slotting. Breaking up the facility into different areas guarantees more orderly location management while reducing bottlenecks. The WMS automates warehouse slotting, ensuring that the goods are deposited and extracted according to criteria predefined by the logistics manager.

- Efficient management with high SKU density. Zoning is ideal in facilities with a high number of SKUs, as it minimizes the risk of errors and unnecessary movements on the part of staff.

- Operator specialization. The division of the warehouse into various sections makes it possible to train operators on the characteristics and conditions of the zone assigned to them. This provides them with more in-depth knowledge of the product and enhances their productivity.

- Versatility. This method can be combined with other picking techniques as the logistics manager sees fit. These include batch picking, wave picking, and semiautomated order prep systems.

However, zone picking does have the odd disadvantage. Its implementation entails limited flexibility when faced with unexpected rises in demand: the division of the warehouse in line with preset criteria prevents more operators from being assigned to a specific section, which could lead to uneven workloads.

How to implement zone picking in a warehouse

The first step to setting up zone picking is to restructure your warehouse layout design. That is, it’s essential to divide it into different areas based on logistics criteria such as product demand, storage conditions, and other rules.

Additionally, for zone picking to be effective, it’s vital to have a warehouse management system (WMS) to coordinate the movements of the operators and the goods automatically — in other words, the system that organizes all the picking phases. The operators, equipped with their RF scanners, merely have to read the label on the container to know which SKUs are assigned to that order and then place them in the bin. The WMS, in fact, replaces all the manual management work: it centralizes all the purchase orders, administers item locations based on rules and predetermined criteria, organizes the warehouse areas, and, lastly, gives operators step-by-step instructions on which products to pick and which container to put them in.

On the other hand, it’s crucial that the warehouse management system (WMS) chosen be equipped to automate the slotting of the SKUs. This way, the software shows the operator where to place each SKU as per criteria established in advance by the logistics manager.

To complement the digitization process, it’s also advisable to swap manual handling equipment and carts for automated systems such as conveyors for boxes, totes, and bins. This equipment connects the warehouse zones, streamlining the container movements. Indeed, warehouses are normally designed with high-turnover products stored close to the automated equipment; this accelerates the flow of the goods to the workstation where the orders will be consolidated and packaged.

In facilities that aren’t automated, zone picking is done with standard carts, small carts with locations for each order, roll containers, or order pickers.

Warehouse zoning in line with logistics criteria

Zone picking is an order preparation method widely used by businesses with high volumes of SKUs in the warehouse. This is because it avoids unnecessary movements by assigning an operator to a specific zone. Nevertheless, putting it in practice calls for a WMS that coordinates operator and product movements, doing away with errors stemming from manual management.

Interested in boosting your efficiency in order prep? Don’t hesitate to get in touch. Easy WMS, the warehouse management system from Interlake Mecalux, is ideal for automating processes in your facility, including picking and slotting.