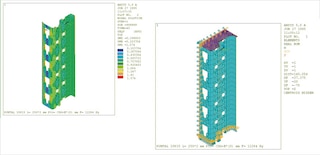

Seismic calculations for racks in Europe

November 2, 2017The highest seismic hazard values and the likelihood of earthquakes occurring converge typically in regions close to the edges of Earth's tectonic plates. In Europe, the countries with the greatest seismic risk are Italy, Greece, Turkey, Cyprus and Iceland. At the same time, in each country, there are areas at higher risk than others. Prevention, as well as the compliance with European standards regarding the design and construction of storage systems, is fundamental for the earthquake-proofing of racks.