BY TERESA DE LA CRUZ

Project Manager, Zaragoza Logistics Center

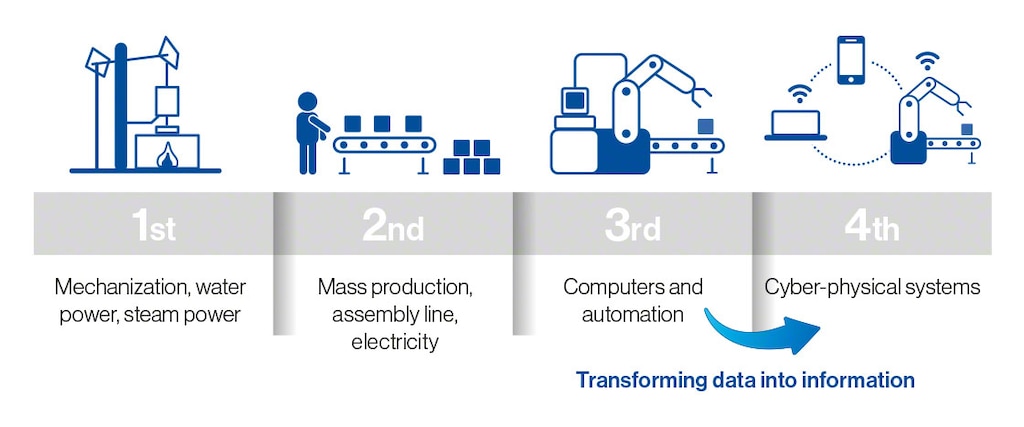

Over the past three decades, logistics has undergone a significant transformation. It started out as a purely operational role that reported to sales or manufacturing, devoted to ensuring the supply of production lines and the delivery of goods to customers. Today, it is an independent supply chain management role that, in some businesses, is already being led by a chief supply chain officer (CSCO or CSO). This transformation has evolved through the years, from the Third Industrial Revolution to the Fourth, and digitization has been key.

Source: Christoph Roser at AllAboutLean.com under the free CC-BY-SA 4.0 license.

Industry 4.0 has made digital transformation a common practice, revolutionizing numerous industrial sectors. For instance, the fields of information, communication, connectivity, analytics, and computing have been reshaped through the use of breakthrough digital technologies. Examples of these include the next generation of communication and networking (5G), the Internet of Things (IoT), artificial intelligence (AI), machine learning, predictive analytics, and cloud computing.

The supply chain and logistics response to Industry 4.0 is the Physical Internet (PI), a global goods transportation system that would work like the internet. This paradigm has been developed for a global logistics system that aims to move, handle, store, and transport supply chain products in a sustainable and efficient way. To achieve this goal, the PI requires a higher level of interconnectivity and interoperability in terms of physical, informational, and operational aspects. Following the principle of the digital internet, this is achieved through an interconnected network of intermodal hubs, collaborative protocols, and standardized, modular, smart containers.

Nowadays, supply chains experience unprecedented challenges. Adopting a PI approach would allow business gains such as lower costs, better customer service, real-time decision-making, and more efficient, resilient, and consistent management of the overall system. Digital trends have greatly impacted the logistics industry because, in the past, it had been entirely dependent on manual processes.

Digital acceleration

The democratization of emerging technology skyrocketed from 2018 to 2020. An MIT study revealed that enthusiasm for technologies such as AI is rapidly growing: 62% of organizations involved in the study increased their spending on AI projects in 2020 compared to the previous year. The pandemic has greatly accelerated enterprises' attention to digital changes. In fact, it has compelled many businesses to reinvent themselves and quicken their transition.

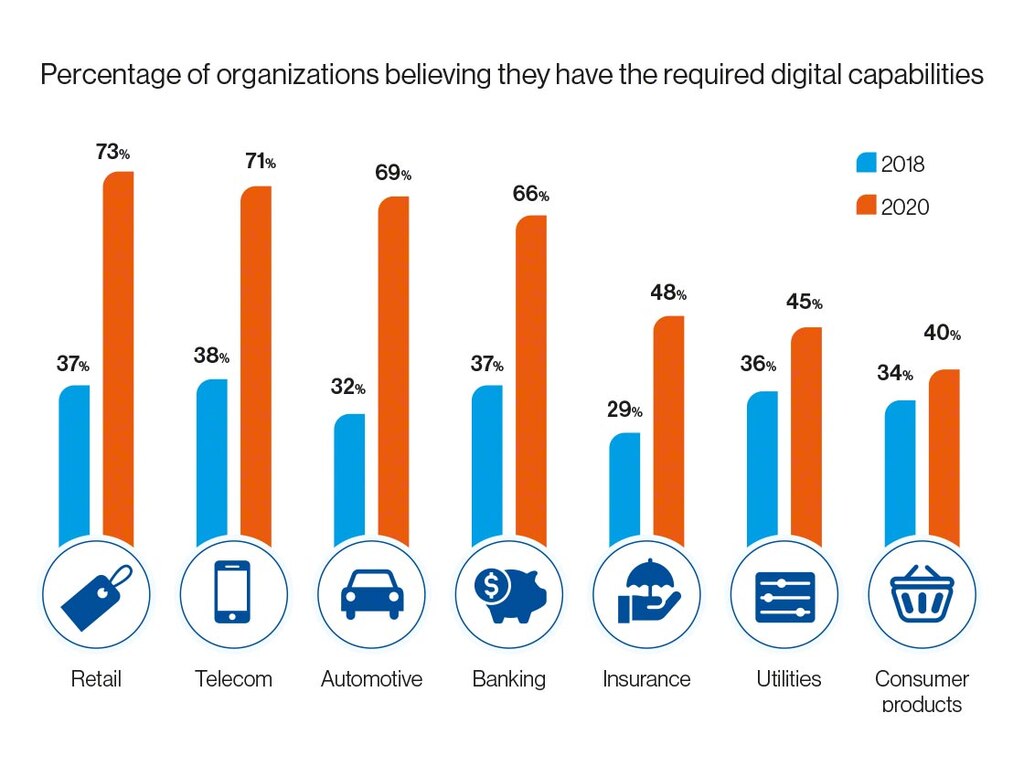

A study by the Capgemini Research Institute shows that 68% of firms think Covid-19 has already accelerated digitization or will continue to do so. All sectors have made strides in their digital capabilities. Among them, however, technology adoption is uneven. In 2020, retail surpassed all other sectors, with 73% of organizations saying they have the digital capabilities required for transformation, up from 37% in 2018. Retailers who recognized the rising consumer demand for online shopping services and embraced e-commerce drove this increase.

Source: Digital Mastery 2020: How organizations have progressed in their digital transformations over the past two years (Capgemini Research Institute).

Adoption of supply chain technologies

Looking towards the near future, there will be an increase in the adoption of digital supply chain technologies as well as technologies that improve human decision-making. For example, according to consulting company Gartner, 75% of large enterprises will have incorporated some form of intralogistics smart robot in their warehouse operations by 2026. These robots address the need to automate certain processes to supplement the human workforce. Compared to more conventional forms of automation like conveyor sorting or automated guided vehicles, robot implementation is quicker and less costly.

Traditional supply chains function according to rules based on historical data, while supply chains integrated with digital technologies function in real time. An article published in Harvard Business Review further explains these dynamics: “For decades, enterprises have embarked on these projects to reshape their supply chains and operations, investing billions of dollars in enterprise resource planning (ERP) systems to achieve efficiency and cost reductions. These systems should have prepared (or provided the foundation for) organizations to handle the cascading disruptions that beset supply chains. However, ERPs may have exacerbated the problems these disruptions cause, because they are designed for static business environments.” New technological platforms allow users to tailor their supply chain requirements through applications that use tools such as AI or machine learning and integrate data from IoT devices.

According to Gartner, 75% of large enterprises will have incorporated some form of smart robot in their warehouses by 2026

Digital maturity

Digital transformation can be described as the set of systemic processes necessary for applying digital technologies. It uses data, information, and intelligence to improve performance and the capacity needed to adapt quickly to disruptive changes generated in the environment.

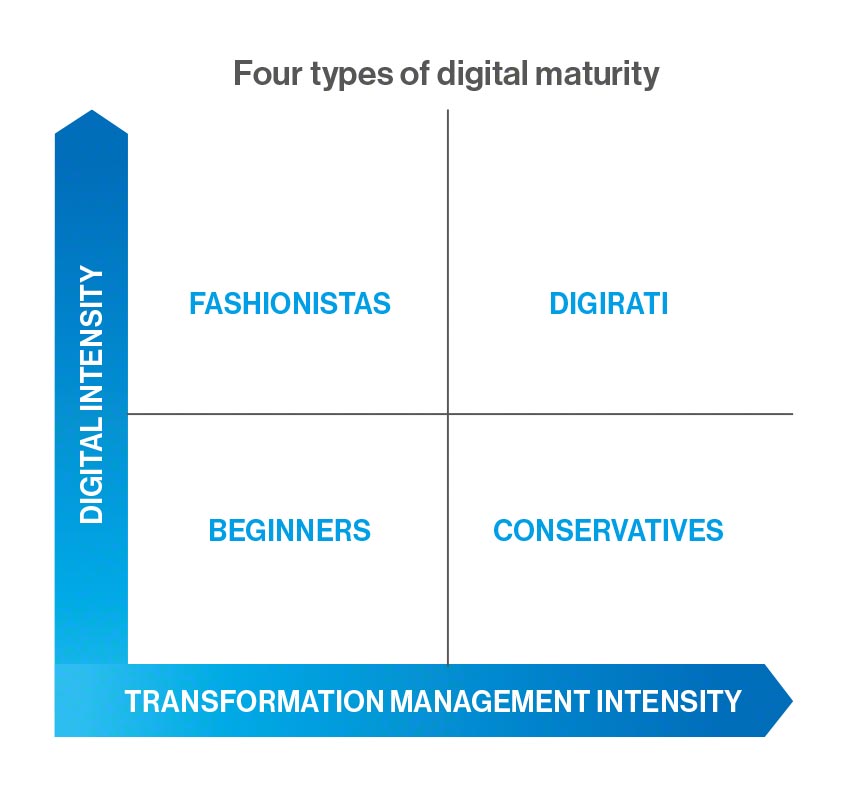

The concept of digital maturity can be separated into two areas. The first is digital capabilities, which indicate the intensity of digital initiatives. The second is transformation management capabilities, which address managerial aspects that drive digital transformation (i.e., leadership, culture, change management, and governance). Companies with strong digital capabilities and weak transformation management capabilities are dubbed fashionistas, while businesses with strong transformation management capabilities and weak digital capabilities are coined conservatives.

Logistics companies face several barriers when implementing technological innovations within their organizations. These include the complexity of the logistics system and underlying processes, a lack of resources (namely skilled resources), technology adoption, resistance to change (both institutional and individual), and data protection/security breaches.

A recent DHL trend report found that the vast majority of logistics workers believe technology has been helpful thus far and feel positive about the growing use of it to support their roles. While technology is viewed as beneficial, most facility operators and office workers felt uneasy about future advancements in automation and AI. However, logistics leaders see a gradual 30-year period of change in which more roles will collaborate with technology instead of competing with it. Digitization offers a wide range of labor market opportunities for higher-skilled workers and those capable of adapting to changed skills needs. Workers with lower skills are encouraged to embrace the transition to digitization and upgrade their qualifications.

This is a challenge not only for the affected workers but also for employers — faced with skills shortages and the need to support workers in adapting to altered production and service provision processes — and institutions.

Success factors for digital transformation

When it comes to digital transformation, the top critical success factors are leadership, an organizational culture that favors this transformation, the engagement of employees and partners in the process, and IT and business teams working together towards a common vision and goal. Good leadership is a critical aspect that, likewise, would foster the other success factors. In this context, leaders are seen as orchestrators of change able to inspire and motivate people to play an active part in the digital transformation process. In addition, leadership is also about providing stakeholders with a vision that clarifies the direction in which the organization is headed and helps guide employees and business partners.

In the larger context of the digital transformation endeavor, a lighthouse project is a brief, well-defined, quantifiable model that acts as a guide (i.e., lighthouse) for additional initiatives of a similar nature. To gain early support from stakeholders, companies should start with projects that have the potential for large benefits with manageable risk.

This is the case of innovative industrial players involved in EU-funded research and innovation projects. The PLANET project investigates novel ways to coordinate complex supply chains through multimodal corridors involving private and public stakeholders. Three real-world living labs were established connecting different TEN-T (Trans-European Transport Network) corridors with China through maritime and rail routes and deploying PI-enabling technologies and concepts. Among other goals, the project has set ambitious targets to improve forecasting, planning, and routing decisions, leading to reduced operating costs, lower CO2 emissions, decreased supply chain disruptions, faster collaborative decisions, and improved end-to-end visibility (including that of end-customers in addition to an improved customer experience).

Digitization, a source of competitive advantage

New technological trends continue to emerge, and businesses adopt them in a variety of ways in an effort to improve current processes and outperform competitors. Industry leaders recognize supply chain technology (both emerging and maturing) as a major source of competitive advantage. Indeed, digital masters have significantly better financial performance than their peers. In order to position themselves for advancements that are undoubtedly on the horizon, organizations are encouraged to modernize their legacy systems and integrate their technology portfolios.

As companies face new challenges in a changing industrial environment, new education curricula at all levels are also crucial. A successful digital transformation sees technology as a means and not an end, relying on a tailored strategy in line with the digital maturity of the implementing organization.

Dr. Teresa de la Cruz is a Project Manager at the Research Office of the Zaragoza Logistics Center (Zaragoza, Spain), where she performs research and management activities in the fields of urban mobility, sustainable supply chains, and transportation systems.

References

- Supply Chain 4.0 – the Next-Generation Digital Supply Chain | McKinsey. www.mckinsey.com. 27 October 2016.

- Maslarić, Marinko, Svetlana Nikoličić and Dejan Mirčetić. 2016. Logistics Response to the Industry 4.0: The Physical Internet. Open Engineering 6 (1).

- Milenkovic, Milos. 2022. Physical Internet: Disruptive Innovation for a Sustainable Supply Chain. Mecalux.

- Crummenerl, Claudia, et al. Digital Mastery – How Organizations Have Progressed in Their Digital Transformations over the Past Two Years. 2021. Capgemini. Paris: Capgemini Research Institute.

- Hippold, Sarah. Gartner Predicts the Future of Supply Chain Technology. Gartner. 20 April 2022.

- Why Legacy Tech Is the Biggest Hurdle to Digital Supply Chain Transformation - SPONSOR CONTENT from GEP. Harvard Business Review. 26 May 2022.

- Fernández-Villacañas Marín, Manuel Antonio. 2022. The New Concept of Disruptive Logistics: Global Sustainable Logistics 4.0 in a Future Post-New World Economic Order. In Handbook of Research on Emerging Business Models and the New World Economic Order, 99–124. IGI Global.

- Future of Work in Logistics. Dhl.com. 2020.

- Mandl, Irene. Employment Impact of Digitalisation. Eurofound. 15 December 2021.

- Home. PLANET Project.

- Westerman, George, Tannou, Maël, Bonnet, Didier, Ferraris, Patrick and McAfee, Andrew. 2012. The Digital Advantage: How Digital Leaders Outperform their Peers in Every Industry. Paris & Cambridge, Massachusetts.