Reducing movements is a great way to improve the efficiency of operators’ work, but it’s not your only option. To go one step further and do away with delivery notes, you could make use of pick-to-light devices.

Example of a pick-to-light system at a pharmaceutical lab

How does pick-to-light work?

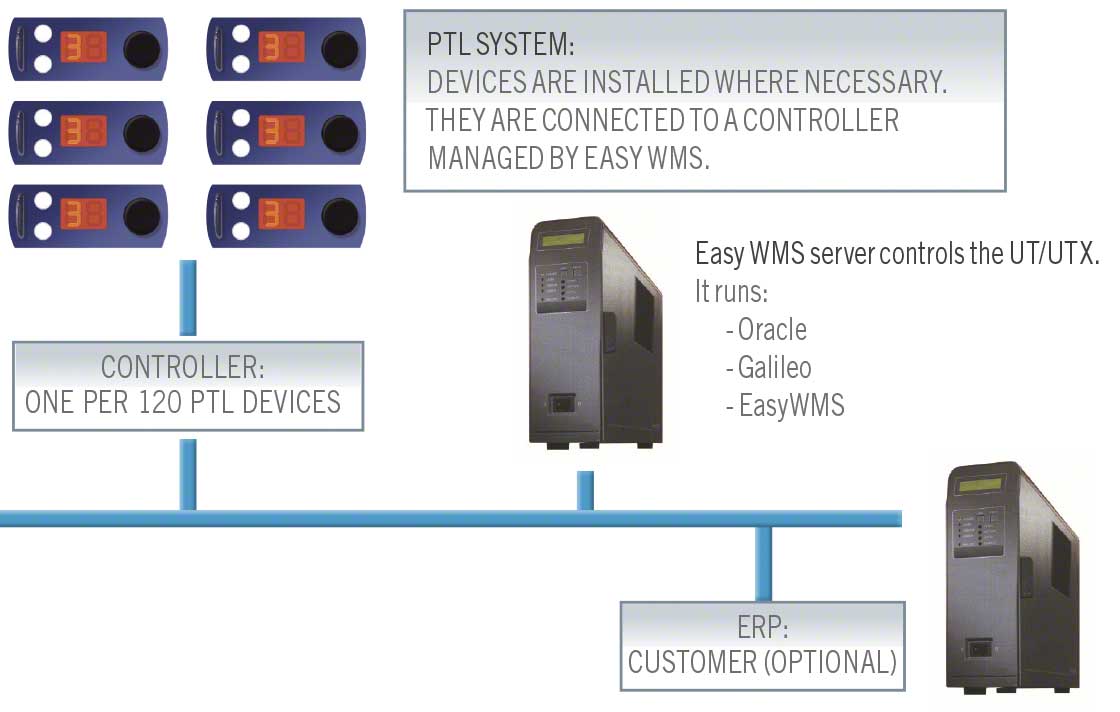

The front of each carton flow channel is equipped with a numerical display with buttons. These devices are controlled by the warehouse management system (WMS). This software lights up the display, prompting the operator to remove goods from that channel and indicating on the screen how many units of the SKU in question to pick.

The operator then scans the location that will receive the goods (this could be the shelf of a picking cart, a crate, or the actual package containing the order). When finished extracting the corresponding units, the worker presses a key to confirm that the operation has been carried out. This informs the WMS, and the light is turned off. When a new order needs to be prepared, the new locations from which products need to be extracted are automatically illuminated.

Pick-to-light devices are extremely versatile and can be used:

- To prepare various orders at once, with one or more operators fulfilling tasks simultaneously (it’s possible to assign a different light to each worker). In fact, the more operators there are working at the same time, the greater use you’ll make of the system.

- With zone picking methodologies, since each worker is assigned to a specific area. This eliminates unnecessary movements and limits the number of devices to install.

- In conjunction with automatic solutions such as the miniload system and roller conveyors, which streamline the transportation of boxes.

- To complement the pick-to-cart method, either because the operators deposit SKUs in picking carts or because the carts are equipped with these types of light-up devices.

Differences between pick-to-light and put-to-light

Both the pick-to-light and put-to-light methods are based on the use of light signals and operate through their connection to warehouse management software. Physical devices, in fact, can be configured to function as pick-to-light and put-to-light equipment. The difference between these two modalities, however, lies in the sequencing of operations:

- Pick-to-light system:

The display lights up, indicating which and how many products need to be extracted from the shelves. Once the operator picks them and deposits them in the corresponding container, the light turns off. Generally speaking, the package is moved by a conveyor for boxes located in the main aisle or below the picking shelf itself.

One example of an installation that implements pick-to-light in this way is that of AS Healthcare (Arvato Bertelsmann), which was designed by Mecalux.

- Put-to-light system:

With the put-to-light system, the luminous display shows the number of SKUs to place in each package or crate on the shelf. Therefore, this system is very useful during the replenishment phase. It’s also used as a device to assist picking.

In this vein, put-to-light can serve to streamline the final stage of order prep. The operator picks products, placing them in a box on the shelf while guided by the put-to-light system. Once the goods have been placed in the box, the worker presses the button, switching off the light.

This implementation of put-to-light is also usually combined with the use of conveyors and other automatic systems, such as miniloads or AS/RS stacker cranes for boxes. In this case, the stacker crane would perform the picking. Once all the SKUs were collected, the operators would arrange them in packages to be subsequently dispatched.

When should I use pick-to-light at my warehouse?

Pick-to-light is designed for:

- Installations with very intense picking activity concentrated in a very specific area that’s limited in size. This way, the cost of setting up the devices won’t break the bank.

- Goods with a medium/high turnover that require very fast shipping.

- Small products that are easy to handle manually. That’s why we talk about packages and crates — most of these products are packed in boxes.

- Installations that already use a warehouse management system. This software activates the lights, displays the messages on the devices integrated into the shelves, manages the stock and updates the database in real time.

Pick-to-light advantages

The implementation of a pick-to-light system reaps major benefits:

- It makes your operations far more flexible by decreasing the number of operator movements. In addition, it takes advantage of the time previously spent on reading, writing down and checking information to prepare more orders, thereby increasing employee productivity.

- It drastically decreases errors made in order preparation. Since verification is immediate, percentages of 99.5% of accurate orders are achieved.

- It’s the assistive picking technology that requires the least training for new hires. This facilitates the integration of operators into your installation.

- It updates inventory information in real time. The system transmits stock movements to the WMS, which records them in the database.

- It consists of mature technology that has incorporated more and more possibilities for the design of the devices and the nature of the messages it displays. This, consequently, provides you with enhanced customization options.

Pick-to-light versus other technologies

Pick-to-light is one of the most established technologies, along with voice picking. Even though these systems vary in terms of their operation and hardware, both voice picking and pick-to-light are geared toward boosting picking ratios, reducing errors and improving overall process efficiency. They represent a natural evolution of radiofrequency picking, which, indeed, resembles paper picking operations (paper is replaced by the terminal display).

Nevertheless, when deciding between one method and the other, it’s always a good idea to take into account the environment in which you’re going to use it: the particular characteristics of the storage installation and of the goods flows.

Let’s compare both methods more in detail:

| Pick-to-light | Voice picking | |

| Number of SKUs |

Designed for high concentrations of SKUs in a specific zone with limited dimensions, as the devices are installed in the shelves.

|

Most effective in large installations with vast inventories, since it allows operators to cover greater distances. |

| Flexibility |

Obtains optimal results when the design of the picking areas remains stable over time, as the device is integrated into the shelf.

|

Allows for changes in picking locations and renovations, since operators carry the devices (here, they’re not attached to the shelves). |

| Solution cost | Proportional to the size of the zone to be equipped because these elements are affixed to the shelves. |

Proportional to the number of operators, since each one carries a device. |

| Productivity | Enables you to reach ratios of 350 order lines per hour and even more; the light makes it possible for operators to anticipate their movements. |

Achieves generally less than 300 order lines per hour. |

| Picking precision |

Nearly 100% accurate thanks to enhancements made to pick-to-light devices.

|

Nearly 100% accurate because checks by voice strengthen the process. |

| Technology maturity |

Mature technology that has continued to evolve since it was first implemented in the 1980s.

|

Mature technology that has improved enormously with voice-recognition software and the elimination of background noise. |

Pick-to-light helps to dispatch orders on time and without error, thus, resolving two of warehouse managers’ chief concerns. The combination of pick-to-light technology with carton flow racks makes this one of the most powerful solutions for installations with small products, many units per SKU and a high turnover.