All of the manual picking options and strategies discussed in the previous sections can be made more efficient with the addition of four technologies: voice picking systems, radio frequency terminals, pick-to-light and put-to-light. All of these can be used to pick from both pallets and boxes.

In the section about "The RFID run warehouse" it explains how the radio frequency system works and the importance of these very useful devices for improving warehouse management. It is important to choose the type of terminal (hand-held, wrist-mounted or truck-mounted) best suited to the work being performed, and to have a powerful and intuitive management program.

Voice picking

Voice picking is based on computer terminals fitted with voice synthesizers and voice recognition systems, whereby instructions can be given and confirmations received through oral communication with the operators preparing an order.

Each operator carries a terminal that includes a headset and a microphone, allowing personnel to keep their hands free. This leads to a considerable increase in the number of operations that can be performed. Furthermore, it is a very good solution for working in cold chambers, since the use of gloves makes it difficult to manage any other type of terminal (think, for example, how difficult it would be to use the buttons).

The voice picking system which is currently used in an automated logistics center

for the storage and distribution of frozen products.

Pick-to-light systems

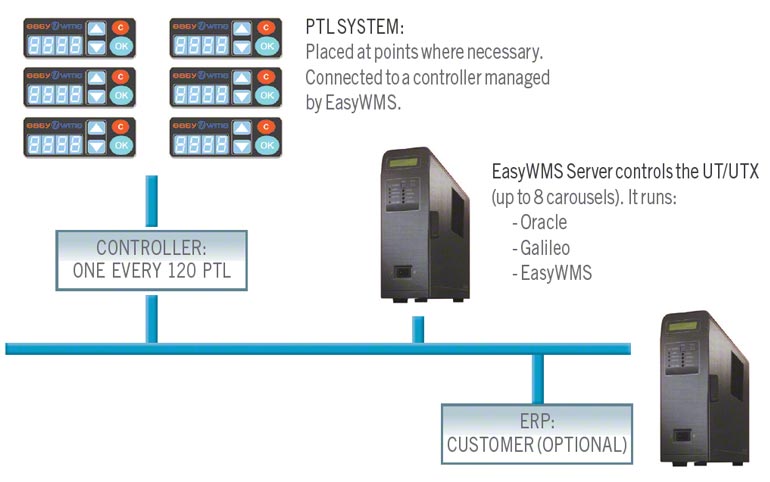

Regarding pick-to-light systems, they consist of several devices with lights and numbers that tell the operator the position they must collect the product from and in which quantity. They are connected to the WMS of the warehouse. In the section on “Storage systems”, the carton flow rack article describes how it works, and how, likewise, they can be used with pallet racks. On the other hand, pick-to-light devices can include lights of various colors, which lets several orders be prepared at once, assigning each color to a different order.

Warehouse built for a company in the pharmaceutical sector.

Put-to-light

The last type of system that can improve picking efficiency is put to light. Put-to-light works in exactly the opposite way to pick-to-light, with the device, which is of similar characteristics, used to indicate to the operator position the goods must be left in and what amount or number. Often these systems are combined. The put-to-light system can be used in fixed positions for pallets, or in mobile equipment in which more than one order is prepared.

How pick/put-to-light systems work.