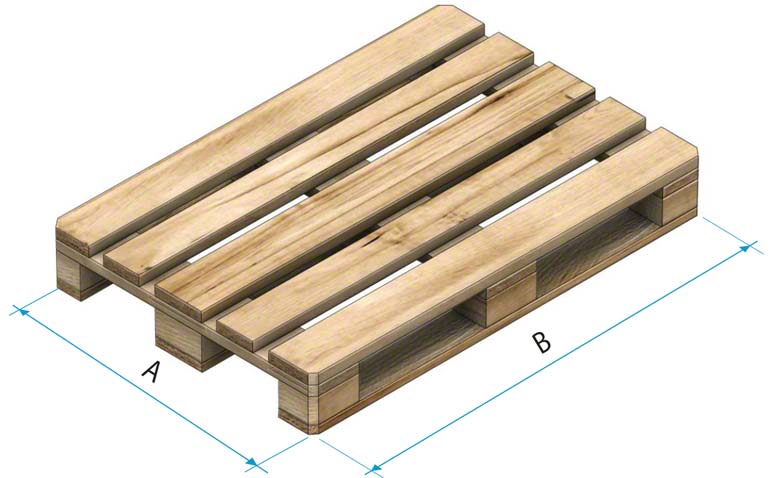

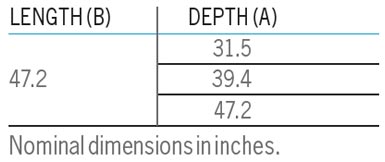

Wooden pallets have widespread use and are built, mainly, in the five models described below. Although the 31.5 in x 47.2 in Euro pallet is the most used pallet size, there are also other common measurements, which include the 39.4 in x 47.2 in and the 47.2 in x 47.2 in pallets. According to the type of load, especially in the sector distributing consumer products, 23 in x 31.5 in pallets are also frequent, and called half pallets as they are half the size of a Euro pallet.

Pallet Type 1

This is the most commonly used model and is the only one that can be used interchangeably in all storage systems, as long as its skids (the lower supports bearing the flat platform where the load will rest) are perpendicular to the beams of the racking units, the support rails or the roller conveyors, as shown in the following illustration:

In each case they must be handled using the side which makes this possible (see the illustration above):

Side A: storage in a pallet racking unit, flow racks and with roller push-back.

Side B: Storage in drive-in pallet racks, push-back with trolleys and Pallet Shuttle systems. Cross-ties for pallets are required in pallet racking units.

| Any type of forklift or pallet handling element can easily handle these pallets. |

| They are ideal for AS/RS warehouses. |

| The only precaution to be taken when using them is to ensure they are of the appropriate quality. |

| There is a European standard which specifies how they are produced. Pallets that meet these specifications are called europallets (see below). |

| Not all 31.5 in x 47.2 in pallets are europallets. Europallets are identified by a circular logo with the letters EUR inside. |

|

39.4 in x 47.2 in and 47.2 in x 47.2 in pallets produced in accordance with europallet specifications and quality are called “europallet type”. |

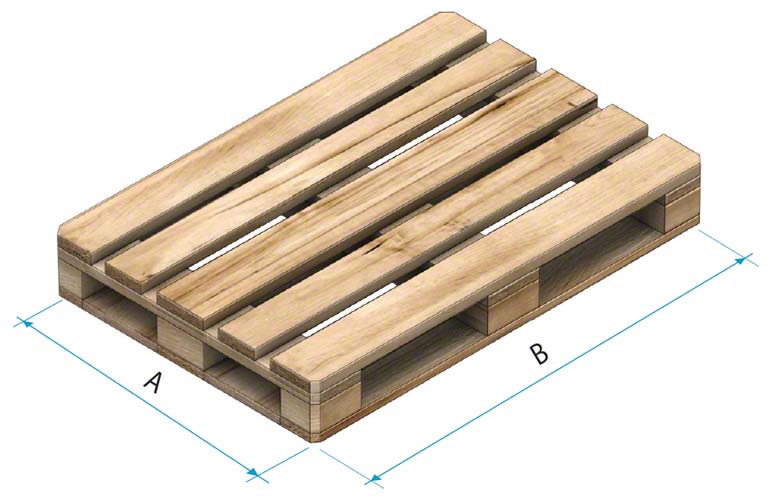

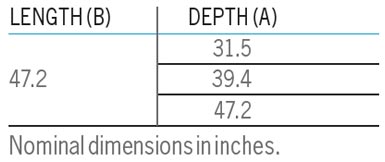

Pallet Type 2

| Type 2 pallets |

| The use of these pallets is quite widespread in some countries (mostly 39.4 in x 47.2 in). |

| They can be stored on pallet racks, drive-in pallet racks, trolley push-back, and Pallet Shuttle racking units. |

| They can cause problems in systems operated by gravity and in roller push-back systems. |

| They are not ideal for use with stacker cranes or bilateral forklifts, except when lifted by the lower part (the bases that link the skids). |

| They are not suitable for handling with stackers. |

| They are not the most suitable type to be used with automated roller conveyors; it is advisable to use automated chain conveyors instead. |

Pallet type 2

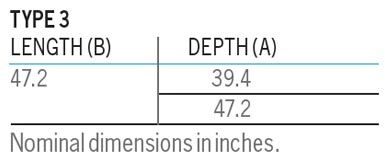

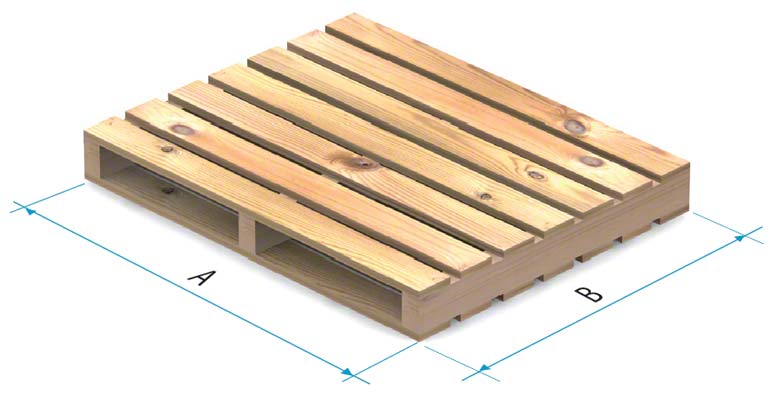

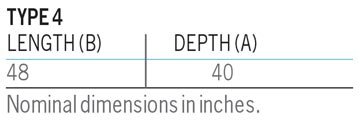

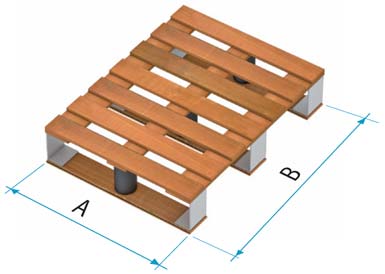

Pallet Type 3 & 4

| Type 3 & 4 pallets |

| These can be stored on pallet racks or drive-in racks, trolley push-back systems, and racking units. They cannot be used in systems with gravity or roller push-back systems. |

Pallet type 3

Pallet type 4

When they are stored on pallet racking units care must be taken with the edges, as the two scenarios described below could occur. These two situations are entirely unacceptable, since they put the safety and reliability of the facility and the load at risk.

The pallet is not well supported by the beam, so it could fall.

The beam is very close to the lower board so the forklift, upon picking up the pallet, could push it and deform the beam.

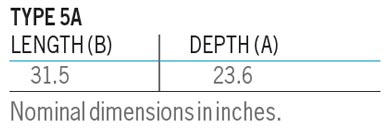

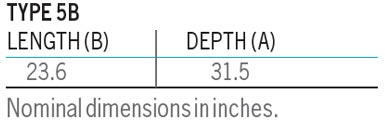

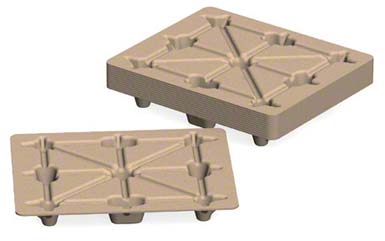

Pallet Type 5A & 5B

| Type 5A & 5B pallets |

| These platforms are also called half-pallets, as their measurements are half those of a 31.5 in x 47.2 in pallet. |

| These pallets are frequently used in the distribution sector for consumer products, since they facilitate distribution of the most appropriate quantities for sale. In addition, thanks to their size, they are ideal for being handled at a point of sale (such as in supermarkets). |

| Equivalent to half a europallet. |

| To store these in pallet racking units, cross ties or a support surface must be placed on the beams. |

| Only 5A pallets can be stored in flow racking units, although with some restrictions. |

| For other uses, they must be positioned in pairs on normal 31.5 in x 47.2 in europallets (when used in this way, these lower pallets are called slave pallets). |

| Any type of forklift can be used to handle them without restrictions, although it is necessary to take into account the measurements of the forks. |

| Unless used with slave pallets, automated conveyors must be specifically designed if these pallets are to be moved. They must either have more rollers than standard automated conveyors or have four chains. |

Pallet type 5A

Pallet type 5B

Other types of pallets

| Other pallets |

| The five types of wooden pallet discussed above are the most frequently used, but not the only ones. |

| There are different standards whereby attempts have been made to establish internationally recognized criteria for production in terms of dimensions, shapes, types of wood, nails, etc. The europallet is the result of such standardization, as will be discussed later. |

| However, there are other pallets that do not comply with this standard, such as those illustrated below. Although they have external measurements similar to those of the europallet, they are not produced to the same specifications and, as a result, may not be strong enough nor have the expected strength. |

| There is a wide variety of formats available other than those of types 1, 2 and 3 (as regards both measurements and construction). All of these cause problems when stored on racking units or when handled using handling elements. This means that specific handling is required and complementary pieces must be fitted to the racking units. |

| Particular care must be taken with platforms described as “single use” or disposable pallets. Although these are of standard measurements, the wood used may be of a thickness and quality which makes them unsuitable for storing directly on racking units. |

These are examples of pallets which could cause difficulties.

Chipboard pallets.

Two openings, double-sided, reversible.

Four openings, double-sided, reversible.

Four openings, double-sided, not reversible (single use).

Two openings, double-sided, not reversible.

Two openings, double-sided, not reversible.

Two openings, single-sided, not reversible.

Four openings, double-sided, reversible.