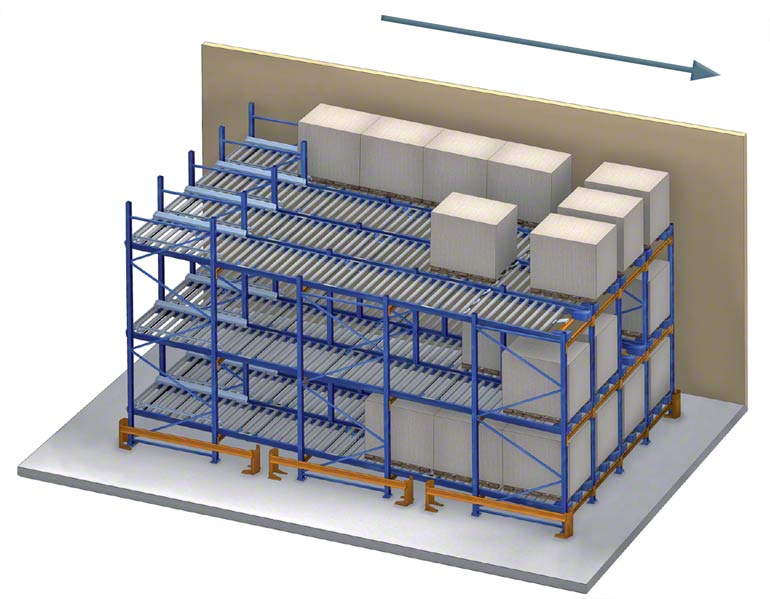

Flow racks are an ideal high-density racking system since using them brings all the storage advantages mentioned in other rack systems.

It is a straightforward system. Each level of each lane is used for a single SKU and has a strip of slightly inclined rollers.

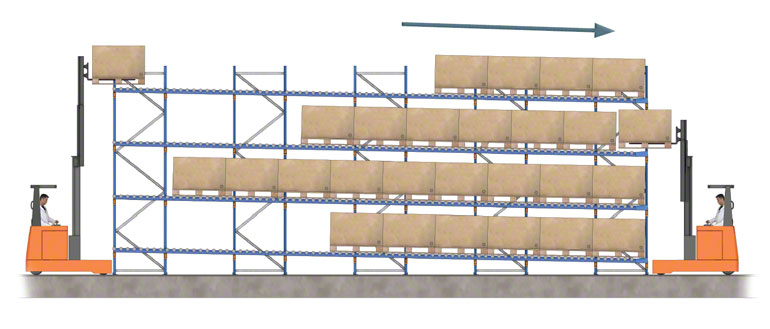

The pallets are placed on one side of the strip and gravity moves them over the rollers until they reach the other end of the strip (which is why they are also called gravity systems). The goods are removed from this far side. The forklifts do not have to move inside the lanes.

With this method, the first pallet that enters the level is the first to exit (FIFO system), which makes for perfect product rotation.

Flow racks use gravity to move the pallets.

Lanes that are more than 65.6 ft deep can be installed. However, the pallets used must be in good condition and have to be of good quality and weight.

This type of solution is best used for storing high rotation perishable goods and continuously flowing consumer goods (constant entry and exit). Two factors must be taken into account when considering this storage system.

The first is that, since the pallets are positioned on a slant, it requires more height than the other compact options, which in some cases can mean the loss of a load level. Furthermore, greater depth requires greater height.

The second observation is that, depending on the size of the warehouse, this can be the most expensive high-density system.

Entry and exit of goods in pallet flow racks.