Nowadays, it is possible to manufacture extremely tall high-rise pallet racking that can reach heights of more than 131.2 ft, although this determines the type of handling equipment required to manage the load in these facilities. Specifically, VNA trucks can be used for racking of up to 45.9 ft, while for higher racking AS/RS stacker cranes for pallets operated through automated systems must be used.

Tall racking is a good way of optimizing available space, since it offers a greater capacity in a limited space without losing the advantages of having direct access to any pallet. This is the ideal situation in any warehouse.

If the building has already been constructed, its height will determine the maximum dimensions of the racks used. If it has not yet been built, the facilities can be designed to allow for the required height and a rack-supported solution may be chosen (an excellent option particularly for buildings over 49.2 ft tall).

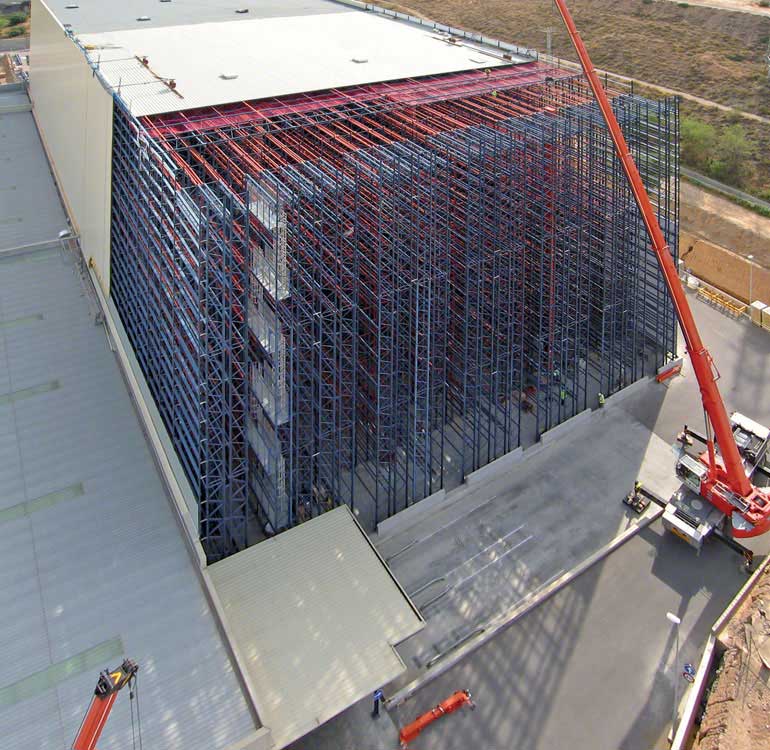

Rack-supported buildings are warehouses where the structure is formed by the racks themselves, which, in addition to housing the goods, also support the walls and roof. These are integrated and very strong buildings, given that the forces they have to bear from wind, snow, and earthquakes are calculated at the time of their construction.

A rack-supported warehouse for the manufacture and distribution of health technology products.

Inside an industrial building for the production and sale of ceramic products for construction.