Retrofit: Reconditioning the warehouse

A retrofit is an opportunity to modernize a warehouse that, for various reasons or simply due to the passage of time, no longer meets its customers’ demands.

What is a retrofit?

Retrofitting involves updating the components that comprise a facility. These might be storage systems, electrical and mechanical components, software, or programmable logic controllers (PLCs). Warehouse renovation allows companies to adapt to new needs and requirements for products, markets, and customers. It’s often a mandatory investment to prevent the original configuration from becoming obsolete.

What is a retrofit in a warehouse?

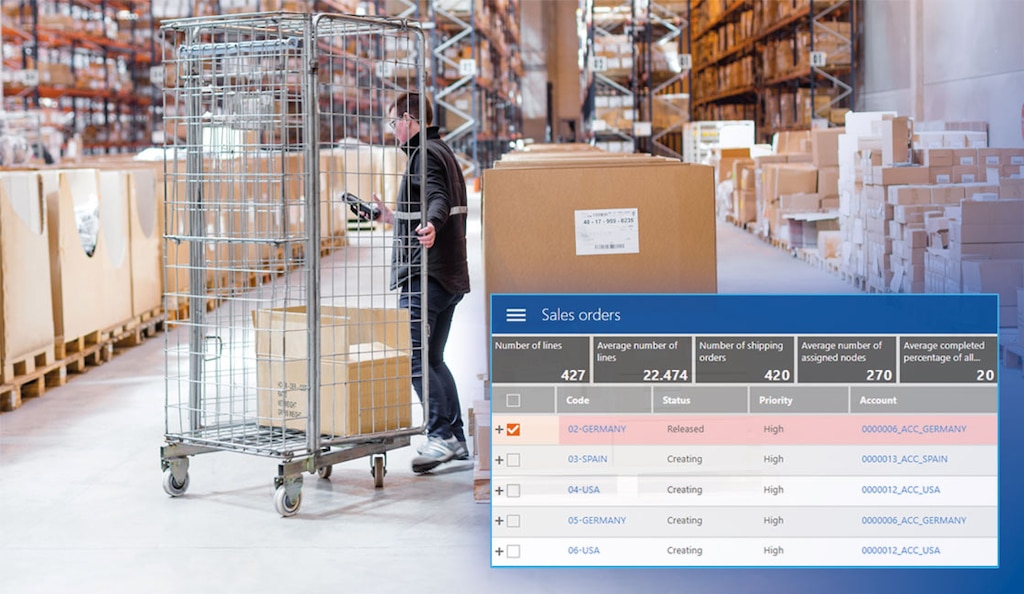

Typically, warehouse modifications linked to a retrofit maintain the original structure and respect designated storage, distribution, and internal transport areas. However, individual elements are modernized to achieve higher throughput and smoother system operation, transforming them, for example, into automated storage and retrieval systems (AS/RSs). In addition to replacing parts such as beams and frames, a retrofit also involves updating the software used in operations.

What is the purpose of a retrofit?

Warehouse reconditioning is necessary to prepare for the future, but it can also have other aims, such as reusing existing resources or increasing productivity. This approach fosters energy savings and emissions reduction without negatively impacting current operations. It almost always allows logistics facilities to continue operating while adjustments are made (if not in full, at least in part).

When should a retrofit be performed?

When assessing whether a retrofit is worth undertaking, it’s important to consider whether the facility’s use remains cost-effective after applying preventive maintenance and whether the retrofit would bring potential savings.

A key indicator of productivity is, for example, the number of items picked per hour. It’s also crucial to consider whether the speed requirements demanded by business logistics, e-commerce, and omnichannel strategies are being met. Warehouses have undergone a real transformation driven by technological advances in recent years. Looking to the future, it’s time to consider whether it’s worth leveraging cutting-edge equipment such as picking robots or autonomous mobile robots (AMRs).

What are the advantages and disadvantages of a retrofit?

Modernizing an existing warehouse instead of building one from scratch in a greenfield project provides multiple benefits to companies:

- Savings and reduction of operating costs. The investment required to retrofit a warehouse is usually less than the cost of equipping one from the ground up. New components also facilitate maintenance and upkeep tasks.

- Nonstop operations. Correct performance means only scheduled stops are carried out, avoiding downtime and lost productivity.

- Improved safety. Modern hardware elements such as positioning systems with computer vision contribute to the protection of goods and operators. Likewise, updating software creates a better defense against cybersecurity breaches.

- Supply of parts. Using systems recommended by expert storage companies guarantees a more secure supply of original spare parts.

- High-density storage. Automated storage systems optimize the use of small spaces, making it easier to accommodate new SKUs. Moreover, in combination with warehouse management software, it’s possible to maintain optimal stock levels in these AS/RSs for successful order fulfillment without overstocking.

Among the disadvantages of a retrofit is that, since some old components will remain in the system, these elements will likely have to be removed before the rest. In short, these are the differences between implementing a retrofit design or opting for a greenfield project:

| Retrofit | Greenfield | |

|---|---|---|

| Advantages |

|

|

| Disadvantages |

|

|

Example of a retrofit warehouse

IKEA Components, responsible for supplying the accessories and spare parts used by the IKEA Group, opted to automate its storage systems in Malacky (Slovakia) without completely interrupting its operations at any point. With the help of Mecalux, IKEA Components automated a pre-existing manual storage system with trilateral stacker cranes for pallets, automatic conveyors, and the Easy WMS warehouse management system. The process was rolled out in four phases and has provided staff with increased real-time inventory visibility.

Retrofit your warehouse with Interlake Mecalux

With its warehouse modernization and consulting service, Interlake Mecalux offers you the opportunity to transform your intralogistics operations through updating, improvement, and redesign processes. Interlake Mecalux advises its customers on how to adapt their logistics operations to market and supply chain demands, either by retrofitting existing facilities or starting projects from scratch.

Are you looking to streamline your operations with the support of an innovative team and leverage the latest technologies? We can help. With over 55 years of experience in intralogistics systems, we know how to optimize our clients’ capabilities. Contact us obligation-free and we’ll find the storage and software solutions with the most potential to take your company’s logistics processes to the next level.