Warehouse organizational chart: purpose and elements

One of the most critical aspects of warehouse management has to do with the capabilities and organization of the personnel responsible for receiving, storing, and shipping goods every day. How is all of this arranged?

What is a warehouse organizational chart?

A warehouse organizational chart is a graphical representation of the structure of this department. It typically includes the roles, responsibilities, and names of the people who compose and lead it, illustrating their hierarchical relationships in a diagram. This tool provides a clear and organized way to visualize how functions and activities are distributed within the warehouse.

According to the Institute of Science and Innovation in Mechanical and Industrial Engineering (INEGI), warehouses and their management are becoming increasingly vital for the supply chain and business outcomes. As a result, the positions in this field have more responsibility and autonomy. Almost all companies have some kind of warehouse, regardless of their size, level of technology, or complexity.

How has the warehouse organizational structure changed in recent years?

The rise in online sales has forced warehouses to evolve — often through automation — to handle quicker, more flexible deliveries without increasing costs.

Customer expectations in terms of service quality are ever-heightened, and order processing involves greater personalization. In today’s changing environment, the warehouse, its organizational chart, and its optimization are crucial for the success of business operations.

How does the warehouse organizational chart impact management?

Traditionally, warehouse management has depended on departments that also encompass other tasks and employees, such as Procurement, Manufacturing, and Logistics. Nevertheless, it might play a more prominent role in organizations whose main activities are related to storage, e.g., logistics providers. Alternatively, it might fall to a lower level in the hierarchy of other types of companies.

These are some ways in which the organizational chart affects warehouse management:

- Definition of responsibilities

- Coordination of activities

- Process optimization

- Improved internal communication

What to consider when creating a warehouse org chart

There’s no single organizational chart model applicable to all companies. An appropriate structure enables your business to achieve its goals using its material and human resources, whether existing or to be incorporated. The basis of a good warehouse department organizational chart is to determine the functions to be performed, design the job positions, group them, and establish relationships between them.

Managers and roles to include in an organizational chart

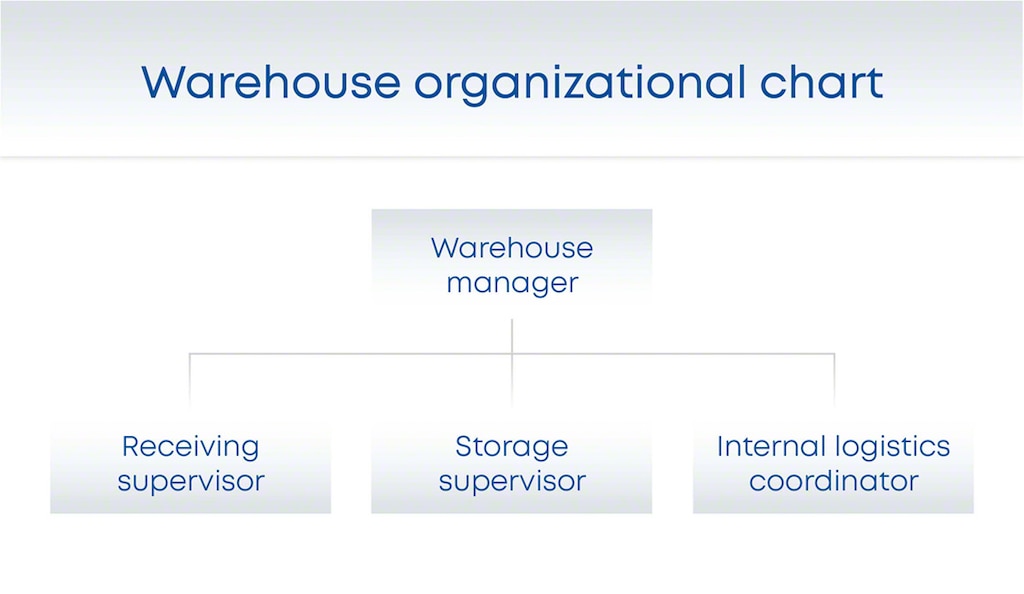

One option for putting together your warehouse organizational chart is to start with your logistics processes and assign a manager to each. This way, the warehouse manager would have the most decision-making authority. At the next level would be the people in charge of subprocesses, such as receiving, storage, and internal transport.

- Receiving supervisor. This individual oversees procedures for inbound goods, from their arrival to their storage. The process includes assigning or scanning an identifier code or RFID tag, which is often incorporated by the manufacturer. This method — together with the use of a warehouse management system (WMS) — ensures full visibility of all products in the facility.

- Storage supervisor. This professional is responsible for assigning goods to the ideal locations, either manually or with management tools. Storage supervisors can assign predetermined slots or use random organization.

- Logistics coordinator. This individual verifies compliance with goods transport rules, both internally and for outbound shipments. The logistics coordinator supervises proper material handling methods for each operation, monitors order fulfillment, and manages production supply.

- Warehouse manager. This professional controls and coordinates all other warehouse operations. These include handling supplier interactions, overseeing staff reporting to them, managing the relationship with Procurement, identifying material needs, preparing reports, and following up on everything pending delivery. Warehouse managers must stay informed about all supply chain links in their business and correct any inefficient processes.

These tasks, relevant to any logistics facility, can be distributed among a supervisor and three intermediate positions. However, you can also assign them to a single person, two workers, or other configurations. Another option is to divide the work of the facility into zones, whether by operating temperature, final destination of the goods, or other criteria.

The ultimate objective of the warehouse organizational chart is for information, products, and raw materials to flow as smoothly as possible in this space within your company. Its structure will depend on the specific needs and characteristics of your business.

Another critical task is keeping the facility clean and orderly. In addition to enforcing occupational health and safety standards, the work environment will be more pleasant.

Adapt your warehouse to its organizational chart

Creating a warehouse staff organization chart and distributing roles among employees and supervisors are essential for successful logistics operations. As mentioned above, there’s no cookie-cutter organizational model applicable to all businesses. Despite that, it’s advisable to use this tool to develop your own organizational chart. You’ll optimize processes, coordinate activities, and improve internal communication in your facility.

Beyond creating your organizational chart, having a modern, automated warehouse adapted to workloads is also a must for supplying production lines, shipping orders, and meeting customer expectations successfully.

Automating and digitalizing your supply chain fosters successful business logistics. The Mecalux Group develops warehouse automation and management solutions that drive efficiency in all types of logistics centers. In fact, we’ve been manufacturing our own metal racks since 1966. Get in touch to find out how to take your warehouse team’s performance to the next level.