Fleet management software: nexus between the warehouse and robotics

Fleet management refers to the effective organization of a company’s commercial vehicles. The increasingly rapid expansion of robotics in logistics environments has led to the development of new systems for controlling groups of mobile robots: fleet management software.

What is fleet management software?

Fleet management software is a computer program that assigns tasks to a group of robots and monitors their traffic in a warehouse, factory, or distribution center. It enables users to configure the machines to transport goods and collaborate in tasks such as order picking. These vehicle fleet tracking systems are essential in automated warehouses. They ensure that devices like autonomous mobile robots (AMRs) coordinate seamlessly with other machines and humans.

What does fleet management software do?

Generally, fleet management programs analyze which robot present in the warehouse meets the following criteria:

- Selection of AMR model. The fleet manager chooses the most suitable AMR for the type of load (pallets, boxes, or racking) and the transfer to be made. Transfers can be performed manually or automatically, via roller or chain conveyors.

- Location of the nearest AMR. The most advanced software programs know which robot is closest to the starting point of the movement to be produced. This optimizes available resources, execution time, and battery life.

These systems also let users configure part of the working environment where the robots will move. AMRs can be issued certain directives such as where to charge, which areas to avoid, and which aisles to travel at a reduced speed. Their navigation routes are defined by an automatic algorithm.

In addition to identifying the right robot for the job and locating it, fleet managers are capable of monitoring other relevant aspects of warehouse operations:

- Load management and optimization. When an AMR is running low on battery, fleet management software can ensure that the only order it receives is to move to the charging area before returning to work. Likewise, these systems leverage off-peak activity periods to recharge, guaranteeing maximum robot availability.

- Advanced mapping. After an autonomous machine has mapped a facility using its sensors and scanners, fleet management software enables users to edit that initial version of the layout. This way, it’s possible to specify certain details to the fleet, such as which zones are off-limits and which areas are designated workstations they can interact with.

How does fleet management software work?

Fleet management software communicates with the various robots in the group. These machines incorporate at least one central processing unit (CPU) responsible for their management. However, they may have several to distribute tasks and ensure low cycle times. For example, one processing unit might control the robot’s movements while another processes information sent by the fleet manager. The fleet manager also receives orders from the warehouse management system (WMS) to coordinate with the company’s other logistics operations.

Users can obtain information about the robot fleet at a glance through the manager. For instance, they can learn details such as:

- Robot status, e.g., whether they’re in automatic, mapping, or manual mode.

- Real-time position and orientation via a SCADA (supervisory control and data acquisition) view, which displays the robots on the map.

- Robot task execution data, such as information on the origin, destination, and goods to be moved.

Benefits of fleet management software

Choosing robot fleets that are compatible with management software offers multiple advantages. Firstly, it saves you from having each robot map the warehouse or workplace individually. Instead, they simply share the path scanned by one machine. Equipping yourself with one of these programs has several other plus points:

- Easy scaling. Often purchased along with the robots, these computer systems make it very easy to integrate a new unit into an existing fleet.

- Saved configurations. You might organize your warehouse differently throughout the year according to seasonal campaigns. By saving your various robot and layout settings, fleet management software allows for simple modification of the work map.

- Increased efficiency. In under a second, a fleet manager can identify the optimal unit for carrying out a task, reducing operational times significantly.

- Unattended operation. These programs enable robots like AMRs to navigate freely without requiring employee supervision. They operate within the work environment configuration set by the implementer and can detect and avoid fixed and moving obstacles. This autonomy frees staff to focus on other tasks.

Fleet management with Interlake Mecalux

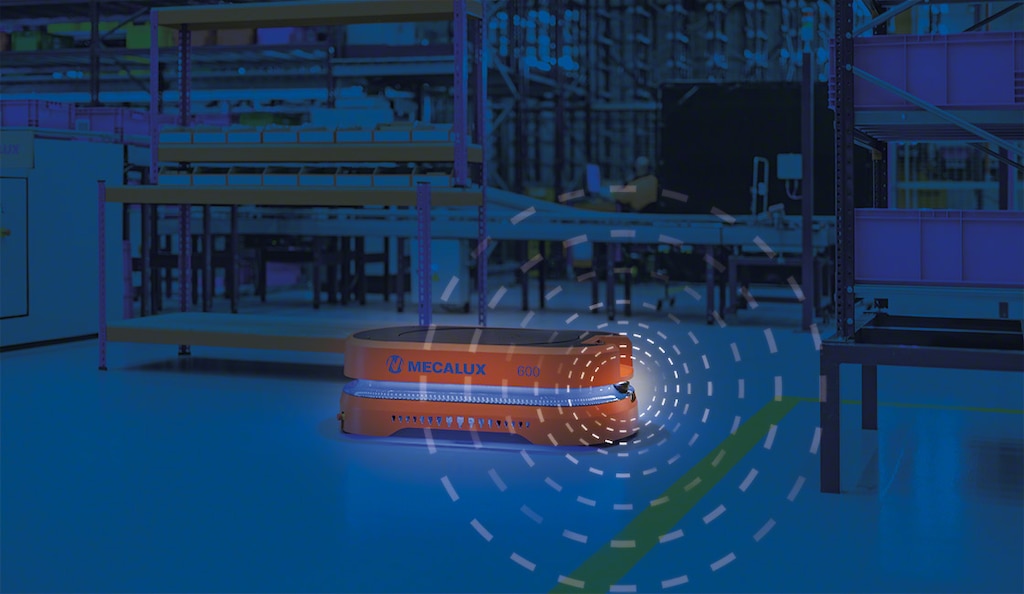

Intelligent vehicles like Interlake Mecalux’s AMRs navigate warehouses independently and streamline internal transport through vehicle fleet management software. It enables users to know the real-time status of each unit (through color codes). They can visualize robots’ locations, whether they’re carrying a load, and what tasks they’re performing. Clients with Interlake Mecalux AMRs have an application to interact with their fleet manager. Among other functions, they can use this tool to create vehicle profiles, edit maps, and send instructions to these robots semi-automatically if desired.

Are you looking to integrate robots in your warehouse and coordinate them to make the most of your investment? At Interlake Mecalux, we can help you with that. Contact us, and we’ll analyze your company’s logistics needs to offer you the solution that matches them. We’re backed by over 55 years of experience and the testimonials of thousands of satisfied clients.