7 formulas for inventory management efficiency

There are multiple formulas for calculating key inventory management parameters in a warehouse. These include the calculation of safety stock for each SKU, product reorder points, the economic costs of a stockout, and the facility’s level of service.

Establishing a method for regularly calculating these key performance indicators (KPIs) is essential in order for logistics managers to make decisions based on the actual productivity of operations.

Main formulas for inventory management in the warehouse

Proper management of stock in a facility greatly boosts productivity in logistics operations and eliminates cost overruns. These are the main formulas for measuring success in inventory control:

1. Lead time

Also known in logistics as cycle time, lead time is an indicator that measures the time elapsed from the moment the warehouse issues a purchase order to a supplier until the goods are received.

Lead time formula:

Lead time = delivery date - order date

If a company issues an order for raw materials on the 15th of each month and receives stock regularly on the 23rd, the lead time would be:

23 - 15 = 8-day lead time

This logistics KPI, measured in days, gives the logistics manager insight into the efficiency of the company’s supply chain.

2. Safety stock

Safety stock is the amount of reserve inventory stored in the facility. These extra goods allow the organization to deal with unforeseen events such as spikes in demand for a product, unexpected changes in SKU turnover, and supplier delays.

Safety stock formula:

Safety stock = (maximum lead time - average lead time) × average product demand

For example, a production center requires 200 units of a product to fulfill existing production orders. If the average lead time is 5 days and the maximum time the supplier takes to deliver the goods is 8 days, the safety stock would be:

(8 - 5) × 200 = 600 units of safety stock

This safety KPI aims to guarantee a certain amount of stock in the warehouse to avoid stockouts, which is what happens when orders are accepted but can’t be filled due to a lack of stock.

3. Stockout

Stockouts occur when the warehouse receives a customer order but doesn’t have enough product to be able to meet that request.

Stockout formula:

Stockout = quantity of stock not supplied × unit cost of storage

That is, if a business can’t fulfill 30 orders, and each order has a value of $2.50, the cost of the stockout will be as follows:

30 × $2.50 = $75 stockout cost

This indicator is often calculated as a percentage, i.e., the number of stockouts per total orders received.

Stockout rate = (quantity of stock not supplied) / (total order quantity requested) × 100

Following the example above, we can calculate the stockout rate as a percentage. If the company is unable to supply 30 out of 300 orders, the calculation will be:

(30 / 300) × 100 = 10% stockout rate

Although this formula is used to show the percentage of unfulfilled orders requested, remember, failure to supply goods to customers leads to other problems, e.g., distrust in the logistics service.

4. Reorder point

The reorder point is a formula applied in warehouses to identify the ideal time for a company to place an order with suppliers to ensure smooth work or production flows and optimize storage space.

Reorder point formula:

Reorder point = safety stock + (average consumption x lead time)

Let’s look at an example that illustrates the reorder point: a business has an average daily stock consumption of 1,000 units and a lead time of 4 days. If the safety stock is 1,000 units, the reorder point will be:

1,000 + (1,000 × 4) = 1,000 + 4,000 = 5,000. Thus, 5,000 is the exact amount of stock to be used as the indicator for issuing a new purchase order to the supplier.

This datum, which needs to be reviewed periodically, provides the logistics manager with the optimal stock volume for goods procurement, taking into consideration the exact balance between investment in merchandise and the risk of stockouts.

5. Maximum stock level

Maximum stock level is the exact number of goods a warehouse can store without running up storage costs.

Maximum stock level formula:

Maximum stock level = (Reorder point + replenishment quantity) - (minimum demand × lead time)

To calculate the maximum stock level, let’s take the example of the company above, which has a reorder point of 5,000 units and a lead time of 4 days. If the replenishment quantity for each order is 8,000 units, and the minimum demand is 1,000 units, the maximum stock level would be:

(5,000 + 8,000) - (1,000 × 4) = 13,000 - 4,000 = 9,000 units as the maximum stock level in the warehouse

This indicator reflects the maximum level of stock a facility can store to provide customers with logistics service at the lowest possible cost.

6. Economic order quantity (EOQ)

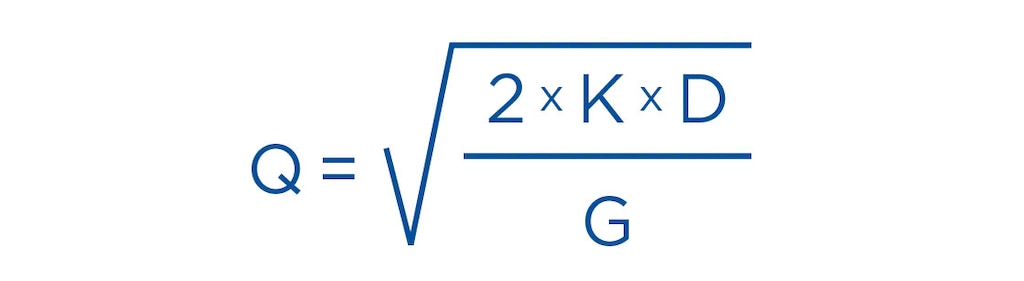

Economic order quantity is a logistics concept that determines when to place an order with a supplier and in what quantity. It is calculated by means of the EOQ formula, also known as the Wilson formula.

Q = optimal order quantity

K = cost of placing each order

D = annual demand quantity of the raw material / product

G = cost of storing the raw material in the warehouse

To simplify the explanation, let’s take this example: an organization needs 500 lb of product to meet the annual demand of its production lines. If the cost of placing each order is $2,500, and the cost of storing the raw material is $25,000 per year, the EOQ will be:

√(2 x 2,500 x 500 / 25,000) = 10 lb is the economic order quantity for having the optimal amount of raw material without increasing storage costs.

The EOQ formula also makes it possible to deduce the number of orders that need to be made annually to satisfy demand. According to the above calculations, the company should place 50 orders a year of 10 lb to reach the 500 lb of product required to fulfill production orders.

7. Stock turnover rate

Stock turnover is a logistics KPI that denotes the number of times inventory was sold over a specific period of time, typically a year. In other words, this parameter measures the number of times that stored products complete the entire business cycle, i.e., they’re sold, leave the warehouse, and payment is collected.

Stock turnover rate formula:

Stock turnover rate = value of SKUs sold / average stock value

For example, if a company sells all its products in a year for a total of $1,600,000, and the average value of the stock in the warehouse is $400,000, the stock turnover rate would be:

1,600,000 / 400,000 = 4 is the stock turnover rate.

Thus, this company has a stock turnover rate of 4, which means it changes its inventory four times a year (once per quarter).

Software for automating stock management

Logistics 4.0 has brought about new challenges in stock management. Nowadays, more and more businesses employ omnichannel strategies ― or multichannel, at least ― whereby orders are dispatched via online sales channels as well as in physical stores. In this panorama, logistics managers are relying on digital solutions that enable them to automate control over their inventory and ensure product traceability. One example of this type of application is warehouse management software such as Easy WMS from Interlake Mecalux. This WMS manages operations in the facility based on parameters such as safety stock, average inventory, and the reorder point.

Additionally, this software from Interlake Mecalux features the advanced Supply Chain Analytics Software functionality. This module monitors the throughput of warehouse operations and automatically collects all information produced in the facility. With these data, the logistics manager can calculate key parameters — e.g., economic order quantity and stockout costs — in a more agile and reliable way.

Stock management formulas: control over everything happening in the warehouse

Logistics managers make use of multiple formulas to know firsthand the status of stock in the warehouse, the costs involved in storing a product, and the price of a stockout.

But more and more managers are implementing warehouse management software to assist them with inventory control. These programs digitize information, automate tasks, and allow management to have all the information they need to make strategic decisions for the facility.

Interested in digitizing your warehouse operations to optimize processes and boost efficiency in inventory management? Don’t hesitate to contact us. One of our expert consultants will advise you on the best solution for your company.