Supply chain mapping

Supply chain mapping enables businesses to monitor their logistics operations. In a constantly changing market, controlling processes — from raw material procurement to finished product delivery — is crucial for anticipating risks and improving competitiveness.

What is supply chain mapping?

Supply chain mapping consists of recording information about the stages and stakeholders in a logistics network. It provides a comprehensive view of every step taken, from sourcing raw materials to delivering finished products to customers.

To create this map, organizations gather information about all the links involved in the supply chain. These can include suppliers responsible for raw material procurement, production facilities that process goods, and logistics centers dedicated to packaging and shipping orders. The supply chain roadmap also highlights the connections between all these players, such as how a company serves its customers through sales channels like physical or online stores.

In recent years, big data has become increasingly prominent in business management. Companies are leveraging vast amounts of data to create more accurate supply chain maps.

Why you should map your business supply chain?

Mapping your supply chain provides transparency and deep insights into the various logistics processes your organization performs, as well as the businesses involved in its operations.

Transparency is a fundamental requirement for consumers; they expect to be informed about how and where their products are made. Moreover, end-to-end visibility enables supply chain managers to detect and address vulnerabilities and potential service disruptions. With a process map in place, organizations can respond more quickly to unexpected issues, such as a supplier’s material shortage.

The transparency provided by the supply chain roadmap also helps identify and eliminate non-value-adding activities, thereby reducing operational costs. This is achieved while ensuring compliance with regulations and quality, safety, and sustainability standards.

What benefits and advantages can you obtain from mapping your supply chain?

Supply chain mapping offers several competitive advantages:

- Improved efficiency. Pinpointing and eliminating bottlenecks and redundancies will enhance operational efficiency and reduce costs.

- Agility and rapid responsiveness. Process mapping enables companies to pivot to changes in demand and address supply disruptions or market fluctuations effectively.

- Optimized decision-making. Supply chain managers can make more informed strategic decisions with accurate, up-to-date data.

- Smooth communication. All supply chain actors gain a clear understanding of their roles, responsibilities, and expectations, fostering teamwork and strengthening the supply network.

- Sustainability and social responsibility. Organizations can identify and mitigate negative environmental and social impacts, building up their reputation and meeting consumer expectations.

- Customer satisfaction. A well-managed supply chain ensures higher product quality, faster delivery times, and more competitive pricing, resulting in a better customer experience.

What businesses should ideally map their supply chain?

All companies can benefit from supply chain mapping. But it’s particularly valuable for those with complex logistics processes:

- Manufacturers. Industries like pharmaceuticals, automotive, and electronics require high precision and coordination to achieve just-in-time production.

- Retailers. These types of businesses — especially e-commerce retailers — rely on efficient logistics operations to manage inventory across multiple facilities and deliver orders on time.

- Food and beverage companies. Tracking the traceability of each product’s journey is essential for meeting regulations and customer expectations.

How can you map your supply chain?

The first step to creating a supply chain map lies in defining the project’s objectives and scope. This may include identifying inefficiencies, managing risks, and improving process visibility.

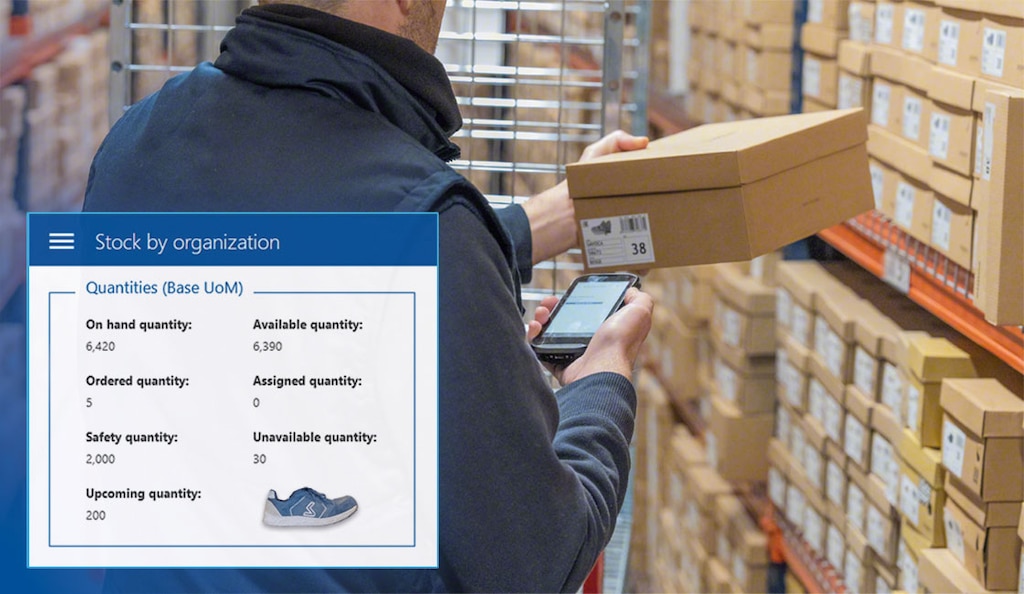

The next step involves gathering data on suppliers, manufacturing processes, storage, distribution, and deliveries. This information should be compiled on a single platform, kept up to date, and made accessible for thorough analysis by supply chain managers.

Interlake Mecalux offers Easy DOM for businesses with an omnichannel strategy. This software centralizes logistics operations for companies managing multiple distribution centers and high daily shipping volumes. This platform connects all supply chain actors: warehouses, ERP systems, marketplaces, call centers, points of sale, third-party logistics (3PL) providers, and carriers.

Effective supply chain management

Supply chain mapping helps businesses maintain effective control over their logistics operations. By using a map, organizations can enhance their operational efficiency and be better equipped to handle changes in demand. Are you looking to optimize your company’s logistics operations? Be sure to contact Interlake Mecalux to learn how our solutions can help you achieve your goals.