Warehouse management system examples in business

Numerous examples of warehouse management systems illustrate how this software is instrumental in controlling, coordinating, and optimizing flows, processes, and operations in logistics facilities.

What are warehouse management systems in logistics?

Warehouse management system (WMS) examples include software solutions designed to organize and supervise tasks within facilities such as distribution centers. Their primary function is to oversee inventory levels, optimize storage, and streamline the flow of goods and their processing for shipment. These systems enable organizations to boost productivity, maximize available space, reduce storage costs, and improve order accuracy and speed, ultimately leading to higher customer satisfaction.

WMSs can also monitor automated elements through predictive maintenance. Through sensors and the Internet of Things (IoT), they track equipment performance to detect anomalies, preventing potential failures to ensure smooth operations.

Types of warehouse management systems

Most WMSs offer two types of architecture: on-premise or the SaaS model.

- SaaS WMS. The software-as-a-service (SaaS) model stores WMS data in the cloud. In this setup, the servers hosting the software are owned by the provider, while the user pays a monthly subscription fee for the license. Spanish electric charger manufacturer Wallbox adopted this model in its Barcelona facility, implementing Mecalux’s Easy WMS to enhance its operations.

- On-premise WMS. This option involves physically installing one or more servers on the company’s premises. The warehouse management system is hosted on-site, and the licenses are owned by the client. The French fashion retailer Espace des Marques chose this approach, installing Easy WMS to streamline its order packaging, labeling, and shipping processes.

What are the most common warehouse management systems?

The most widely used warehouse management systems are powerful tools designed to support multi-facility networks. These WMSs feature intuitive, user-friendly interfaces that allow teams to operate efficiently without needing to memorize SKU locations or codes. This significantly improves safety while providing full traceability of inventory.

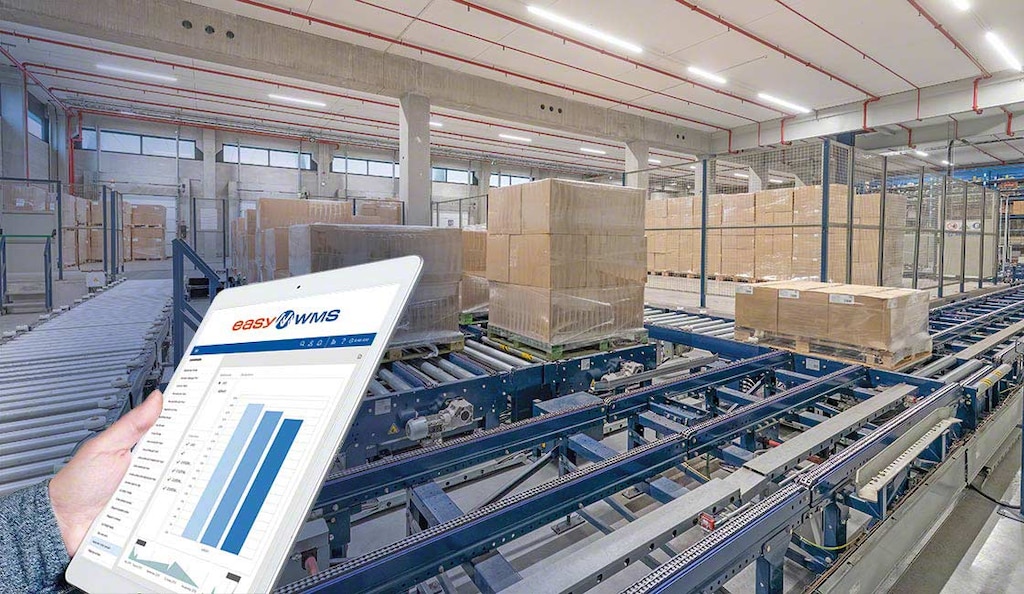

Easy WMS is a warehouse management system continuously evolving to meet the needs of modern logistics. It was developed by the intralogistics experts at Mecalux, a global leader in storage solutions since 1966. This software powers the operations of hundreds of facilities across 36 countries and is supported by teams dedicated to implementation and technical assistance.

Advantages of the most powerful WMSs

Top warehouse management systems address critical operational needs, including:

- Intelligent warehouse management. They assign storage locations, sequence tasks, and automate information flows. These features offer real-time inventory visibility and streamline the receiving, order picking, and shipping processes.

- Seamless integration with other systems. A reliable WMS integrates effortlessly with leading ERP software and automated storage and retrieval systems (AS/RSs).

- Flexible, scalable implementation. The best solutions receive continuous updates without requiring service interruptions, ensuring adaptability as business needs evolve.

Additionally, adopting a WMS enables the integration of voice picking systems. This technology guides warehouse associates through verbal instructions for enhanced efficiency and reduced errors.

WMS software examples in business

Hundreds of companies are using Mecalux’s Easy WMS, but not all leverage the same applications. This is because the end-to-end system designed by warehousing experts features advanced modules that expand its capabilities according to business requirements. So, what warehouse management system examples exist based on company type?

- Multi-Carrier Shipping Software. GreenlandMX, an online store for off-road motorcycles and spare parts, installed Mecalux’s Easy WMS in its facility in Valdorros (Spain). The warehouse management system organizes shipments with carriers through the Multi-Carrier Shipping Software module, which generates labels, packing lists, and all necessary transportation documentation.

- WMS for 3PL. The German industrial services company WISAG uses this advanced Easy WMS feature to provide its clients with complete control over their inventory, tailor logistics processes to their specific requirements, and create detailed billing reports.

- WMS for Manufacturing. Moderna Products makes “smart plastics for happy pets.” It implemented the WMS for Manufacturing module in its Izegem (Belgium) plant. This capability integrates its automated rack-supported building by Mecalux with its production lines, ensuring the traceability of raw materials.

- Value-Added Services (VAS). The French fashion brand Rouje, created by and for women, personalizes some of its shipments to provide a unique customer experience. Using Easy WMS’s VAS functionality, associates can determine, for instance, whether an order should be delivered in a tote bag and know exactly where to place it in the package.

Optimize your logistics operations with Interlake Mecalux’s WMS

The Mecalux Group developed Easy WMS to help you organize your operations more efficiently, with total visibility. If you’re looking for comprehensive control over your facilities and inventory while ensuring seamless logistics operations, get in touch with us. With over 55 years of experience in intralogistics, more clients are satisfied with our services every day.