Today’s distribution journey: 5 ways to defy the odds in warehouse logistics

A revolution in how distribution logistics is run has been upending warehouse operations year after year. In charge of getting the finished product to the end customer, the warehouse is where you strike while the iron’s hot!

What layers does a logistics ecosystem have? Dealing with this question is vital to identifying the main challenges warehouses must face in logistics distribution and challenge the odds in today’s market.

A warehouse’s role in the distribution logistics journey

Like a river, distribution logistics flows through different stages, such as:

- Estimating demand: This is a highly useful skill to prevent stock-outs or lack of performance when faced with peaks in activity.

- Purchasing intelligently: Having and following a smart, proper buying plan stands as a central pillar in terms of purchasing power and cost savings. In this context, exact info on stored stock and carrying out an exhaustive inventory count is fundamental.

- Managing a warehouse: It includes the day to day operations carried out in your warehouse. From reception and location of goods to their delivery, organizing everything else in the entire order fulfilment and product packing process.

- Selecting transport and distribution channels: A warehouse’s or distribution center’s location is as big a decision to make as any because it will affect all activities or how your distribution river flows.

- Managing orders and receivables: Once you’ve successfully surfed the waves with your orders, pending receivables or payments need to be reeled back in.

Riding the rapids of today’s distribution logistics

To ride the rapids (the constant, changing currents) of distribution and its logistics, it is important to ID the challenges shaping the present and future logistics practices for distribution.

1. Optimize process planning to reach breakneck speeds

Damming off downtimes in distribution logistics is an aim that depends in large part on having a precise planning process or processes. Gauging and identifying areas that need improvement turns into a sink or swim situation when keeping your competitive edge afloat. So that’s why it is well worth adapting each of your operations to the specific requirements of each company or sector. Open-ended real-time info will help you make decisions and control in progress operations being executed down to the last detail.

2. Plug the dam, i.e., floor space shortages and their cost imply

Distribution logistics has created a subsector inside the real-estate market. Not surprisingly, industries and businesses have spent years renting and using larger and larger warehouses, mainly due to the overflowing demand from e-commerce.

This high demand for space converges in large logistics complexes within a country (e.g., Chicago, Dallas, Seattle) and has prompted a recorded-breaking flood in warehouse occupancy in the property sector, according to research by the American Transport Research Institute (ATRI). This trend deluges square footage costs with the challenge now being to recover and improve the installations’ productivity.

3. Resuscitate your storage spaces to get a solid grip on profits

But how do you max out space usage and cut operator task times in a warehouse? Tackling the design or redesign of ever-changing storage spaces is one of the main challenges that distribution logistics has to steer through.

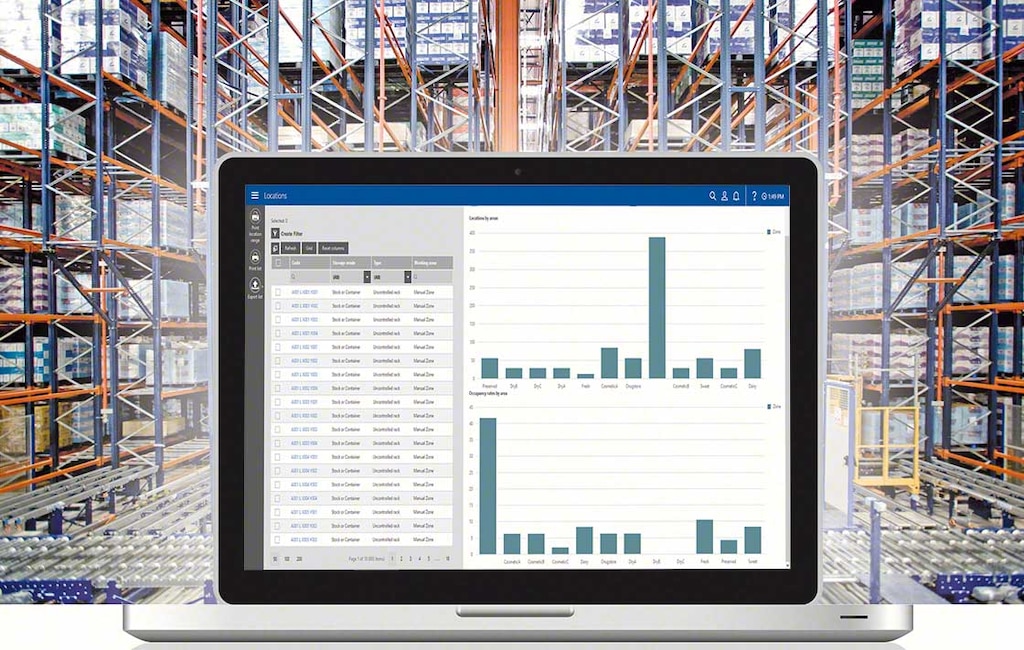

Storage can present a real design conundrum the more complicated the space or if tech-based operations dominate the waters, whether you’re talking automated storage system or a specialized software.

4. Getting good people to stay and motivating your team

Though it might seem like a stream of robots is taking over warehouses, the work done by operators continues to be fundamental for all types of warehouse labors. It’s not hard to find warehouses in which there are highly automated zones while other zones feature primarily manual operations (e.g., preparing orders).

Major objectives built into any global business strategy in distribution logistics always include suitable training and motivation, while also blocking off cost leaks.

5. Integrate and coordinate the twists and turns of distribution logistics

Lastly, a tightly linked distribution logistics chain is the widest river to swim. Transport systems, order commands, in-warehouse operations, payables, … Each process must flow into the next and, to do so, technology comes to the rescue to blend your logistics perfectly.

The rising tides of the market demands continue to transform operations linked to distribution logistics. However, the good news is that tech solutions are adapting to the new and changing business landscape.