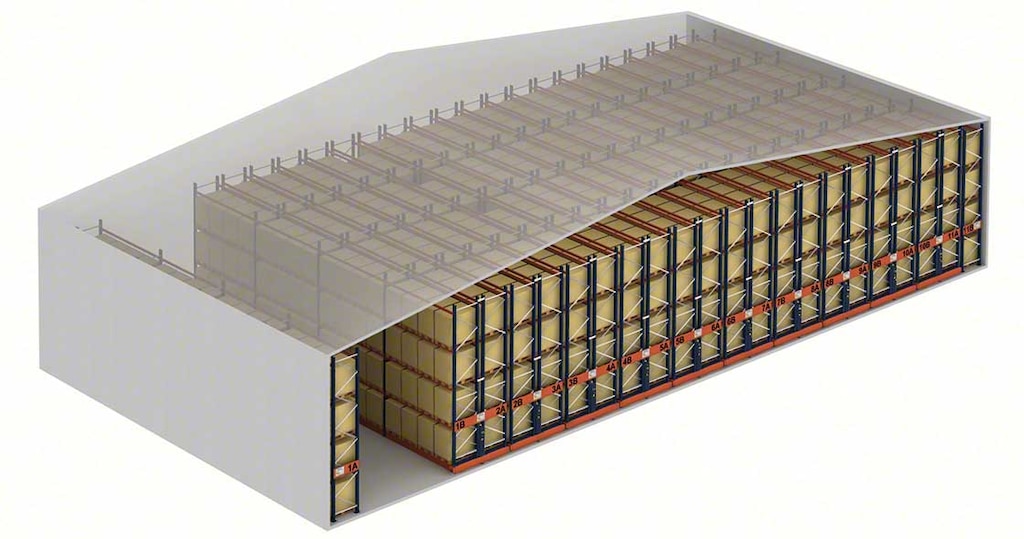

Mobile Racking Systems: Take advantage of every inch of space

Although static racking is one of the most versatile warehouse installations, its storage capacity can be significantly less than other more innovative options such as mobile racking systems. Take advantage of this advanced system to fully optimize available storage space by eliminating the necessity of multiple static aisles.

How do mobile racking systems work?

This storage strategy can initially seem complicated, however its unique characteristics and adaptable design make it easier to install and operate than you might expect.

- The system is composed of moving blocks of racking units.

- Operators have direct access to multiple shelves by entering a single working aisle.

- Mobile bases are guided on rails installed in the flooring and can be controlled manually or electronically.

- Operation speeds can be increased when mobile racking units are controlled by computer so that the opening and closing of aisles is programmed.

- Safety systems automatically stop the movement of mobile racking if an obstacle or person is encountered in its path.

What are the advantages of investing in mobile racking?

Despite the fact that mobile racking technology has been around for quite some time, many distribution facility managers don’t fully grasp how significantly it can have a positive impact on their operations and costs. Here we summarize some of the various ways mobile racking systems can greatly improve your warehouse strategy.

- Allows for direct access to pallets.

- Versatile design permits for storage of load units of varying sizes.

- Are typically designed with a single aisle, however several blocks with multiple aisles can also be considered when racking units must be accessed more frequently or if there are a very large number of racking units.

- Increased product safety thanks to airtight seals between racking units.

- Operating times and labor costs are reduced, while simultaneously improving overall productivity.

- Throughput is enhanced due to the reduction in operating times and the increase in the number of products placed and picked during a given period of time.

When should mobile systems be used?

Mobile racking systems have a variety of different storage applications, however there are certain factors that you should consider when deciding if this is the appropriate solution for your company.

- An excellent solution when there is a need to increase warehouse capacity.

- Recommended for operations which only require a minimal number of forklift trucks.

- Ideal for storing low and medium rotation products.

- Is not considered appropriate for storing pallets which must be moved very frequently.

- Especially useful for small and medium-sized cold chamber warehouses. The total volume of storage space to be cooled is reduced significantly, thereby increasing energy savings and positively affecting the return on investment. Discover how Havi Logistics took full advantage of mobile racks to double the storage capacity of their distribution center.

There’s no argument that conventional static racking can be an effective storage solution for many facilities and that it offers a certain amount of versatility for various warehouse operations. Nevertheless, the unique characteristics of mobile racking systems bring the possibilities of storage space optimization to an entirely new level. This, along with increased product security and reduced operating times, makes it an ideal solution that more and more logistics experts are turning to.