Supercapacitors and their role in industrial automation

Supercapacitors are an innovative, revolutionary way to store energy, expanding the capabilities of traditional capacitors. Nowadays, they are seeing more and more applications in the industrial and logistics sectors.

What is a supercapacitor?

Supercapacitors — also known as electrochemical capacitors or double-layer capacitors — are systems made up of pairs of conductive plates separated by a dielectric medium. Their capacitance can be thousands of times greater than that of electrolytic capacitors, and their charge and discharge speed is directly proportional to their capacity.

The first supercapacitors, with a capacity of just one farad, were developed in the 1970s and 1980s. The Japanese multinational NEC started marketing them in 1978 to support computer memory. Today, these devices reach capacities of up to 5,000 F, outperforming batteries due to their high power and superior stability after long usage cycles.

Advantages of supercapacitors

- Shorter charging times. Like traditional capacitors, supercapacitors require time for charging and discharging. However, this process can take minutes instead of hours.

- More energy in less time. Supercapacitors store less energy than batteries. But they deliver a greater amount to consumers in the same time frame.

- Safety. Unlike electrochemical batteries — which are inherently unstable in the face of external variables such as temperature — these devices cannot explode.

How do supercapacitors work?

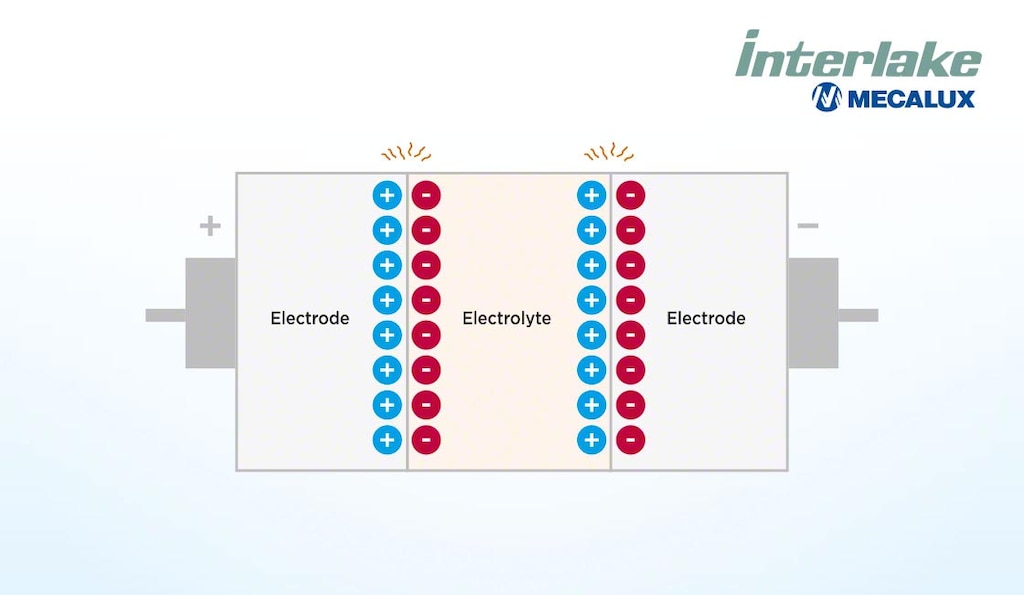

Supercapacitors store energy electrostatically, but they retain and release it differently than batteries do. They are made up of three key components:

- Electrodes. These are two facing plates that attract electric charges: one plate attracts positive charges and the other, negative. The amount of accumulated electric charge a supercapacitor can store — its capacitance — is proportional to the size of the plates and inversely proportional to the distance between them.

- Electrolyte. The plates are immersed in a liquid that aids the movement of electric charges within the supercapacitor. The electrolyte also provides conductivity and insulation.

- Insulator. The two electrodes are physically separated by a layer that prevents the two surfaces and their charges from coming into early contact. This insulator creates a magnetic field that helps store large amounts of electrostatic energy.

Supercapacitors vs. batteries

Supercapacitors are more energy-efficient than batteries. They are used to generate power surges and are made with non-toxic, non-corrosive materials, resulting in less waste.

| Supercapacitors | Batteries | |

|---|---|---|

| Lifespan (cycles) | >100,000 | <1,000 |

| Specific energy | Moderate (<10 Wh/kg-1) | High (13.5-68 Wh/lb-1) |

| Specific power | Very high (2 kW/kg-1) with 95% efficiency, low impedance | Moderate (0.5 kW/kg-1) |

| Charging time | Less than five minutes or even seconds | 10 to 60 minutes |

| Electrochemical reactions | Minimal activation polarization | Significant activation polarization |

| Storage mechanism | Physical | Chemical |

| Power limitation | Electrode surface area | Electrode mass |

What are supercapacitors used for?

Because of their characteristics, supercapacitors come in handy in multiple industries. They have a variety of applications:

- Energy support. They handle demand peaks without causing overloads in the power grid, smoothing energy supply and covering short-term supply interruptions.

- Solar panels and other renewable energies. Supercapacitors act as voltage stabilizers.

- Vehicles. Supercapacitors can serve as a power source for starting large engines. They can also be part of regenerative braking systems in diesel trucks or locomotives. Moreover, they are compatible with hybrid cars and hydrogen systems.

Where are supercapacitors used in a warehouse?

This technology is also increasingly employed in areas closely linked to logistics and manufacturing. One prime example is industrial automation.

High-density storage systems such as the Automated Pallet Shuttle are becoming popular in warehousing. Supercapacitors are their primary power source — especially when produced by top manufacturers. This ensures that the pallet-transporting shuttle cars are always available and can operate continuously (24/7). Companies like United Caps and Panificadora de Alcalá have already integrated them into their facilities.

Supercapacitors protect machinery and equipment from abrupt supply interruptions, optimize operational efficiency, and contribute toward creating efficient manufacturing environments. This makes them an appropriate choice for logistics and production settings.

Supercapacitors: an evolving technology

Since their invention in the 1970s, supercapacitors have continued to incorporate improvements and new materials. For instance, researchers at the Technical University of Munich have developed a highly efficient graphene supercapacitor. Meanwhile, engineers at the Massachusetts Institute of Technology have created a supercapacitor with three primitive materials commonly used since the Roman Empire: water, cement, and carbon black.

This invention could have significant applications in energy supply and the maintenance of electrical distribution networks, particularly if integrated into the foundations of homes. Additionally, efforts are underway to apply this technology in communication satellites, flight control systems, and electric propulsion for spacecraft.

Enhance your logistics performance with Interlake Mecalux

Are you looking to streamline your operations with the latest technologies in partnership with an innovative, resourceful team? At Interlake Mecalux, we’re here to help. Our company has upgraded its products continuously for over 55 years to optimize our clients’ capabilities. Contact us without obligation, and we’ll show you which storage and software solutions have the greatest potential to take your logistics operations to the next level.