Warehouse simulation software

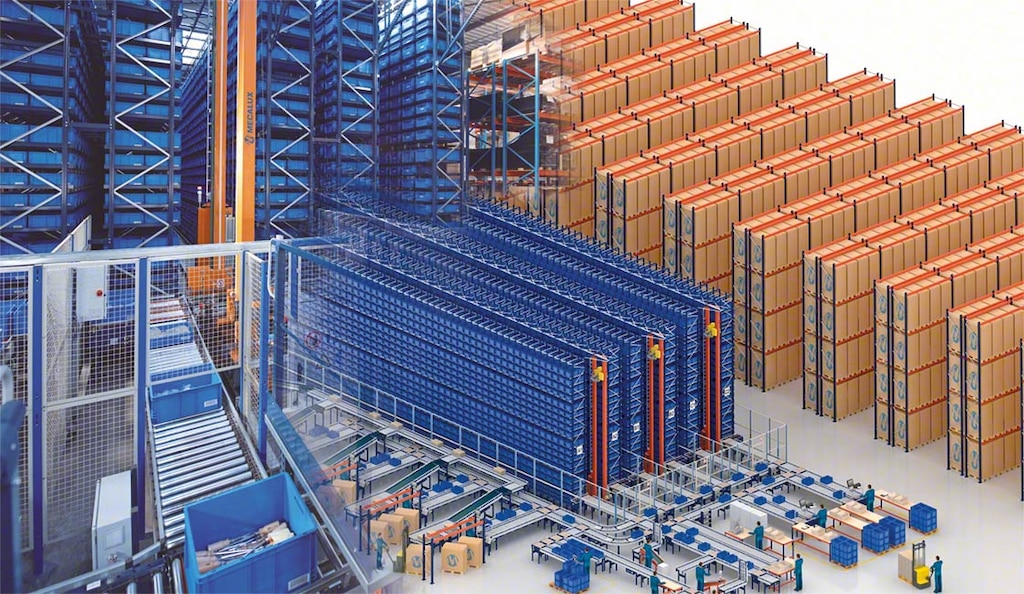

Warehouse simulation software is a program used to create a virtual representation of all the elements found inside a logistics facility that will play a part in its proper operation: the goods, the storage systems, and the handling equipment, among others. This technology runs a number of tests to predict the performance of the warehouse and check, for instance, whether the incorporation of new storage systems or logistics processes will affect productivity or whether bottlenecks could occur.

Real data from the logistics facility are added to the digital warehouse model. These include, e.g., the number of orders to be prepared and product inflows and outflows to foresee how operations will be carried out. With a warehouse simulator, you can design the solution that best adapts to anticipated requirements and verify that they will complete the required cycles and provide the highest possible storage capacity.

Once the virtual representation of the warehouse has been created, you can predict how the logistics facility will respond to different scenarios. This can be done even for specific situations, such as an increase in order processing due to the implementation of an omnichannel strategy or the arrival of peak season.

Why use warehouse simulation software?

Simulation is a very powerful resource that serves to design, predict, and optimize the warehouse layout. By creating a virtual representation, supply chain managers can identify improvement opportunities to get the most out of the different operations.

These are some of the elements that can be analyzed with warehouse simulation software:

- Storage systems. One of the simulator’s basic functions is to determine the optimal storage system. Taking into account the goods flows and the available space, the software comes up with a solution that houses all the products and facilitates operations.

- Handling equipment. In the virtual representation of the warehouse, you can choose the most appropriate handling equipment based on the available height, the width of the aisles, and other requirements particular to the facility. In the case of automated storage and retrieval systems (AS/RS), you can decide on the most suitable quantity and type of stacker cranes, for example.

- Optimal resources. The virtual warehouse model helps to improve operations and, thus, to foresee which resources are essential for performing each task. It also allows you to estimate the number of operators needed for the operations planned.

- Flow of movements. Simulation produces an animated 3D rendering of the entire facility in which you can see operators and unit loads in action. This solution simulates the ideal movement flows inside the warehouse so as to avoid, for instance, potential bottlenecks that would interrupt service. Likewise, it’s possible to represent increased flows throughout the facility or in specific operations.

Once all these areas of activity have been verified with the help of the warehouse simulation software, the logistics managers can plan the day-to-day operations in the facility. Through simulation, routes and processes can be optimized to make the warehouse effective and profitable.

Warehouse simulation software from Interlake Mecalux

When Interlake Mecalux carries out a project, it uses three programs to simulate and configure the operation of its facilities: Easy M, Easy S, and Automatic Warehouse Studio (AWS).

With this technology, Interlake Mecalux’s technical team tests the operation of the facility, confirms the validity of the theoretical calculations for the required flows, and detects areas for improvement (i.e., bottlenecks) before putting the warehouse into service. This software’s primary function is to shorten project implementation times.

For simulation to be as realistic as possible, Interlake Mecalux’s technical team analyzes data for each project, such as daily number of entries and exits, number of items available, and stock turnover.

The Interlake Mecalux technical team employs each of these three systems in different stages of the project:

Planning: Easy M

When a customer considers installing a new storage solution, Interlake Mecalux uses Easy M. This technology simulates facilities equipped with the Easy WMS warehouse management system. It also validates the productivity of solutions to be implemented in the facility so that any necessary improvements can be made before start-up.

Through simulation, Interlake Mecalux’s technical team can guide customers that need to carry out highly complex projects on the most appropriate storage solution to achieve their objectives. Easy M also lets users reproduce situations in which the customer’s requirements are stepped up; for example, it can increase the number of orders and movements in the warehouse.

When the simulation is finished, Easy M generates a report specifying possible flows of movements in the warehouse, the workload, and downtime. The report is supplemented by an animated 3D rendering of the entire designed facility, in which the unit loads can be seen in motion.

Configuration: Easy S

Once the decision has been made to implement the project, the Interlake Mecalux technical team uses Easy S software to run advanced simulations that more accurately reflect the warehouse’s future throughput. This tool configures and designs automated warehouses equipped with Interlake Mecalux management software.

With this technology, the team can decide on the best location for the racks and the movements that the automatic handling equipment should make (namely, the stacker cranes and conveyor systems). To configure the facility, Easy S applies real data from the warehouse and the Easy WMS management software. This allows Interlake Mecalux’s technical team to produce much more exact 3D simulations and to validate the solution in much more detail before launching the product.

Easy S also includes another key function: it optimizes operations in warehouses that are already up and running, implementing improvements in design and testing their throughput.

Development and start-up: Automatic Warehouse Studio (AWS)

To ensure the correct operation of the automated warehouse, Interlake Mecalux also uses Automatic Warehouse Studio (AWS). This software configures and tests the automated handling equipment. AWS provides an extremely reliable 3D simulation of the project. The representation is highly realistic and shows how the warehouse machines will move.

During the project development phase, Interlake Mecalux engineers perform tests to verify the performance of the handling equipment with the help of AWS. The software generates a simulation representing the real performance of the machines. The technicians can then make all the necessary changes to the handling equipment, e.g., modify the position of the sensors.

Once the project has been implemented, with the machines already operational in the warehouse, the AWS simulation serves to continue checking the correct operation of the handling equipment and fine tuning it, for example, adjusting the variable-frequency drives.

With the facility up and running, the AWS simulation also helps warehouse managers to check the status of operations. Warehouse users can verify the performance of the handling equipment and detect malfunctions, if any.

Warehouse simulator: security in the face of uncertainty

Logistics is a demanding industry that modernizes itself constantly to adapt to market changes. The priority of any company is to have an effective warehouse that provides the desired level of service.

To design a logistics facility, warehouse solutions providers leverage the advantages offered by warehouse simulation software. This makes it possible to predict future operations and make the right decisions in advance.

At Interlake Mecalux, we have extensive experience using software to simulate our customers’ projects and find the perfect storage solution to meet the most challenging logistics needs. Be sure to get in touch; we’ll show you how to drive operational excellence in your facility.