What is cross-docking? Types and how it works

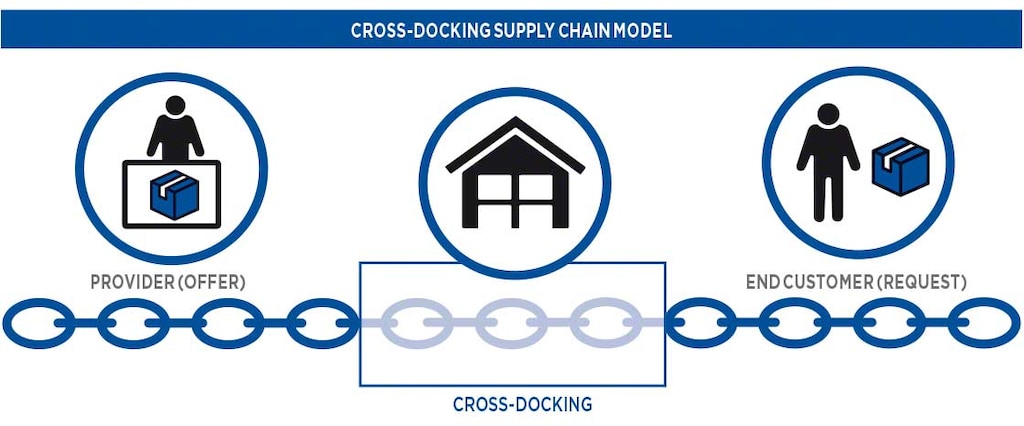

Cross-docking refers to a type of order preparation in which goods are distributed directly to the user without going through a pre-storage period. It makes little difference whether the products are raw materials, finished goods or components destined for factories, physical stores or end customers. Cross-docking can be adapted to any of these situations.

Following the cross-docking strategy means the goods remain in the warehouse for a very short time after receipt. In addition, the goods are not placed on your racks and, therefore, the picking process is skipped. The term originates from this alternative process, as the operation simply requires crossing the docks.

Let's take a closer look at what this logistical activity is good for and the most commonly used types of cross-docking.

How do cross-docking operations work?

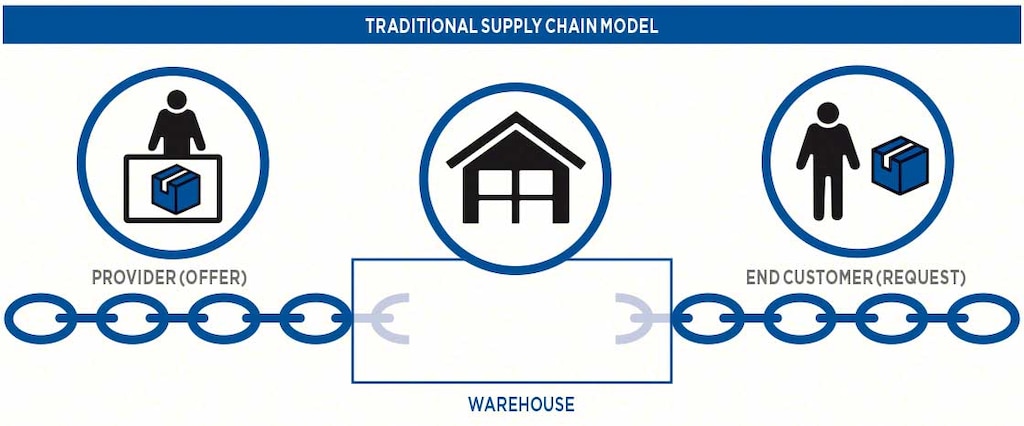

In a traditional supply chain, the warehouse represents a key link that connects providers (supply) with consumers (demand). This flow is discontinuous, since supply and demand are not synchronized and the warehouse fulfills the role of a central hub. The goods are stored there until demand gives the green light.

However, the advancement of information systems and software applied to logistics has led to increasingly agile and integrated supply chains. It is in this context that cross-docking finds popularity, since the perfect coordination of all those involved is a prerequisite for it to work successfully: suppliers, warehousers, transporters and end users.

Even within the warehouse itself, a powerful warehouse management system is required as an indispensable tool to respond effectively to cross-docking requirements.

Phases of cross-docking

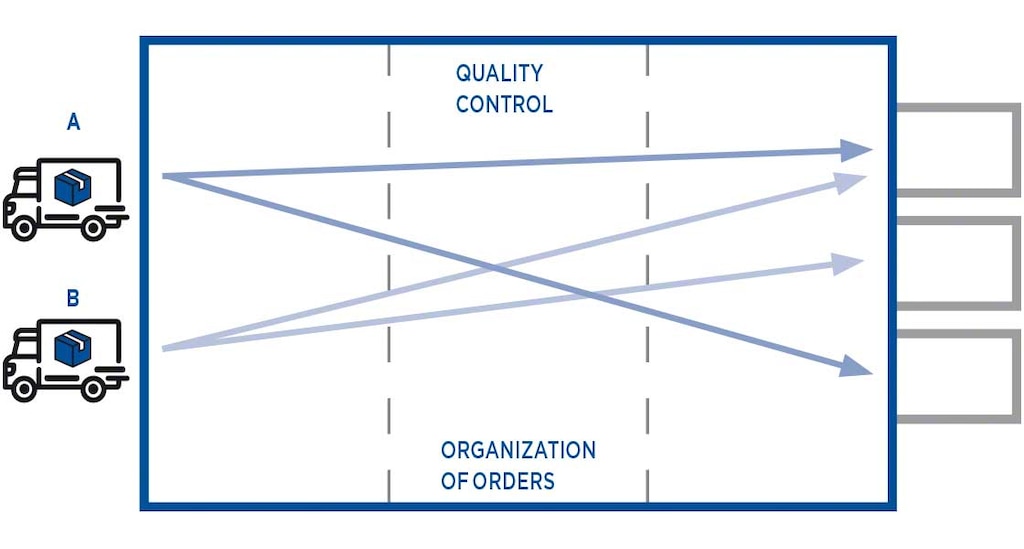

In general, we can conclude that the main phases of a cross-docking operation are:

- 1. Programming of distribution by suppliers.

- 2. Receipt of goods in the warehouse.

- 3. Recording and review of the received load as part of the quality control process.

- 4. Repacking, order consolidation (if necessary) and dispatch of the goods.

Cross-docking types

Cross-docking activities can be carried out with different unit loads (pallets, boxes, kits, etc.). There are different ways to organize the different types of cross-docking, but taking into account the steps required to do so, we would especially highlight:

1. Predistribution cross-docking

Predistribution represents the most basic cross-docking model. In this mode, unit loads are already prepped and organized by the supplier taking into account the final demand. Therefore, the cross-docking operation is "reduced" to receiving the goods and dispatching them without further involvement by warehouse workers.

2. Consolidated cross docking

In a consolidated cross-docking scheme, goods must be handled in to adapt them to the end customer’s requirements. Then, the received unit loads are moved to a cross-docking or conditioning zone where they are examined and adjusted to the requested orders.

- This may involve arranging pallets from smaller unit loads or vice versa: dividing the goods into individual packages or product kits.

3. Hybrid cross-docking

This is a more complex type of cross-docking that involves preparing orders in the conditioning zone by taking part of the goods from the received truck loads and come from stock already stored in the facility. In these cases, the received goods can be moved to a temporary storage area instead of directly applying cross-docking.

It is a more flexible type of cross-docking, which allows a greater variety of situations to be dealt with, but also requires effective coordination of all the tasks linked to this operation.

Cross-docking is not a new concept, but many companies are using it to meet the needs of their omnichannel supply chain. In any case, before adding it to your order picking strategies it is important to know the advantages and disadvantages of cross-docking and the situations in which it has proved to be a successful business tactic. Only then will you be able to assess the suitability of this practice in your company.